Clean method for preparing borate intercalation hydrotalcite-like compound

A hydrotalcite compound and borate intercalation technology, which is applied in the direction of alumina/aluminum hydroxide, can solve the problems of washing water consumption and low use value, and achieve the effect of saving washing water and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step A: Mg(OH) 2 , Al(OH) 3 and H 3 BO 3 Mix according to the ratio of Mg / Al molar ratio of 2:1 and B / Al molar ratio of 3:1, take 10g of the mixture and place it in 80g of deionized water to make a highly dispersed suspension and transfer it to the reactor;

[0024] Step B: Control the temperature rise under stirring conditions. When the temperature rises to 105°C, remove the air in the reaction system through the exhaust valve, continue to heat up to 200°C, and react for 24 hours. The reaction slurry is directly filtered and dried at 70°C. 24h, get B with Mg / Al=2 3 o 3 (OH) 4 - Intercalated hydrotalcite-like compounds.

Embodiment 2

[0026] Step A: Mg(OH) 2 , Al(OH) 3 and H 3 BO 3 Mix according to the ratio of Mg / Al molar ratio of 2:1, B / Al molar ratio of 3:1, take 10g of the mixture and place it in 80g of deionized water to make a highly dispersed suspension and transfer it to the reactor;

[0027] Step B: Control the temperature rise under stirring conditions. When the temperature rises to 100°C, remove the air in the reaction system through the exhaust valve, continue to heat up to 220°C, and react for 6 hours. The reaction slurry is directly filtered and dried at 80°C 4h, get B with Mg / Al=2 3 o 3 (OH) 4 - Intercalated hydrotalcite-like compounds.

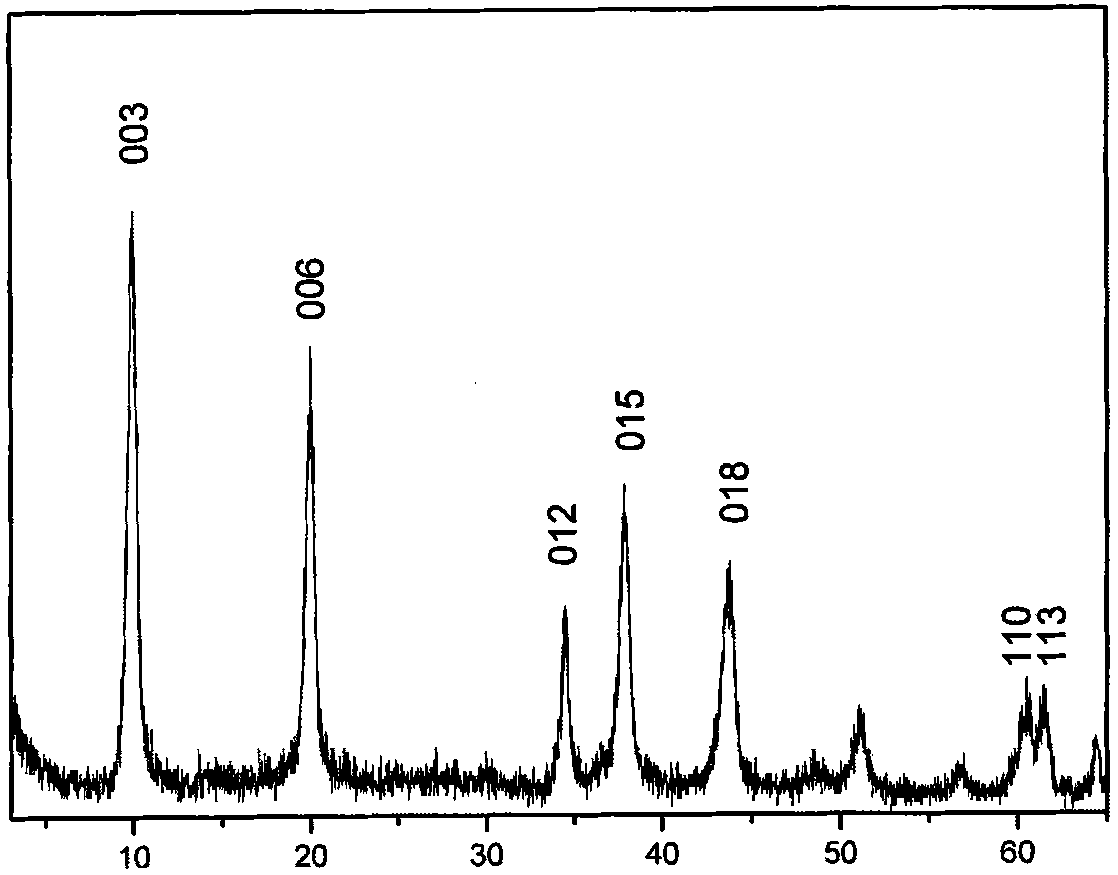

[0028] The crystal structure of the sample was characterized by XRD-6000 X-ray powder diffractometer from Shimadzu Corporation, Japan. figure 1 is the XRD spectrum of the obtained sample, as can be seen from the figure, (003), (006), (012), (015), (018), (110 ) and (113) crystal plane diffraction peaks appear at 2θ=10.1°, 20.2°, 34.6°, 38.0°, 43.8°,...

Embodiment 3

[0033] Step A: Mg(OH) 2 , Al(OH) 3 and H 3 BO 3 Mix by Mg / Al molar ratio of 3:1, B / Al molar ratio of 3.2:1, take 10g of the mixture and place it in 80g of deionized water to make a highly dispersed suspension and transfer it to the reactor;

[0034] Step B: Control the temperature rise under stirring conditions. When the temperature rises to 98°C, remove the air in the reaction system through the exhaust valve, continue to heat up to 220°C, and react for 4 hours. The reaction slurry is directly filtered and dried at 60°C. 4h, get B with Mg / Al=3 3 o 3 (OH) 4 - Intercalated hydrotalcite-like compounds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com