Vacuum adsorption molding method for realizing continuous production

A technology of vacuum adsorption forming and forming area, which is applied in the fields of leather, applications, household appliances, etc., can solve the problems of shortening the forming cycle and low efficiency, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

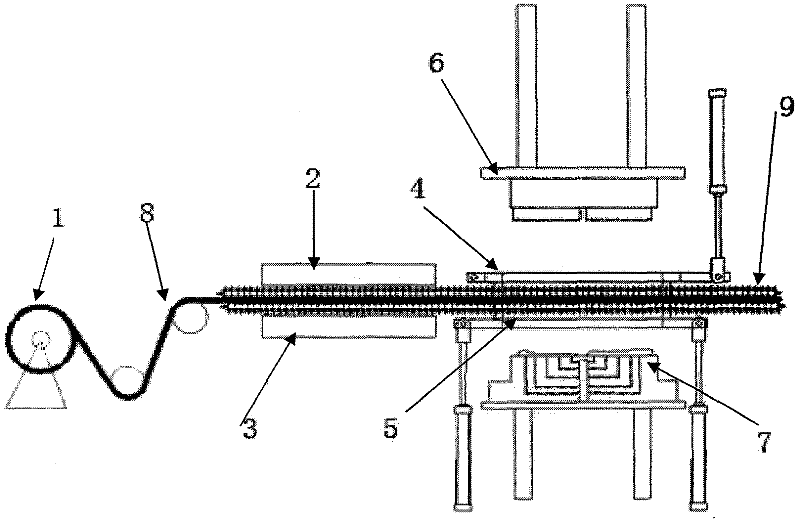

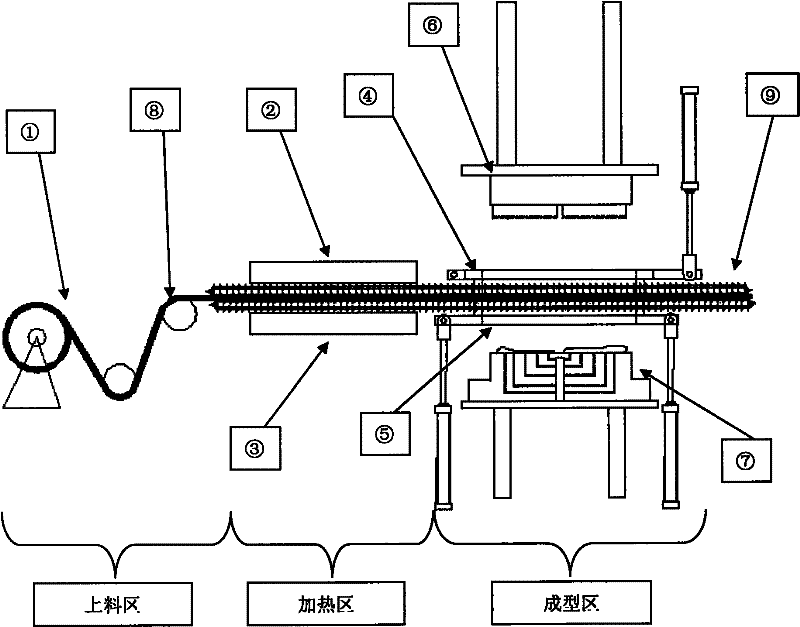

[0019] see figure 1 , the specific implementation process of this method is as follows:

[0020] ①First place the roll of leather material 8 on the film winding machine in the feeding area 1

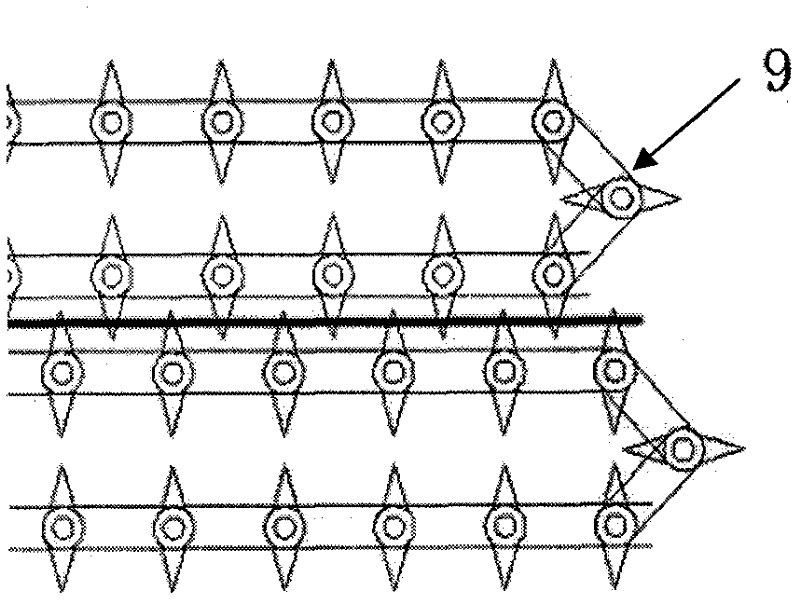

[0021] ②The leather material is occluded by the upper and lower racks 9 (see figure 2 ) to move into the baking zone,

[0022] ③Bake the leather in the upper furnace 2 and the lower furnace 3 in the baking area

[0023] ④ After the leather reaches the baking temperature, it is driven into the forming area by the rack 9 (at this time, the lower leather enters the baking area for heating)

[0024] ⑤ After the leather material reaches the forming area, the upper pressing frame 4 of the forming equipment moves downward under the drive of the upper pressing frame cylinder and clamps the leather material together with the lower pressing frame 5

[0025] ⑥After the lower mold 7 of the molding equipment is raised to the position driven by the lower mold motor, the lower mold is vacuumed, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com