Outer circle grinding workpiece surface quality visualization real-time monitoring method

A workpiece surface, real-time monitoring technology, applied in the direction of the machine tool designed for grinding the rotating surface of the workpiece, the parts of the grinding machine tool, grinding/polishing equipment, etc., can solve the problems of signal interference and sensitivity, sensor installation difficulties, etc., to achieve The effect of improving grinding quality and improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

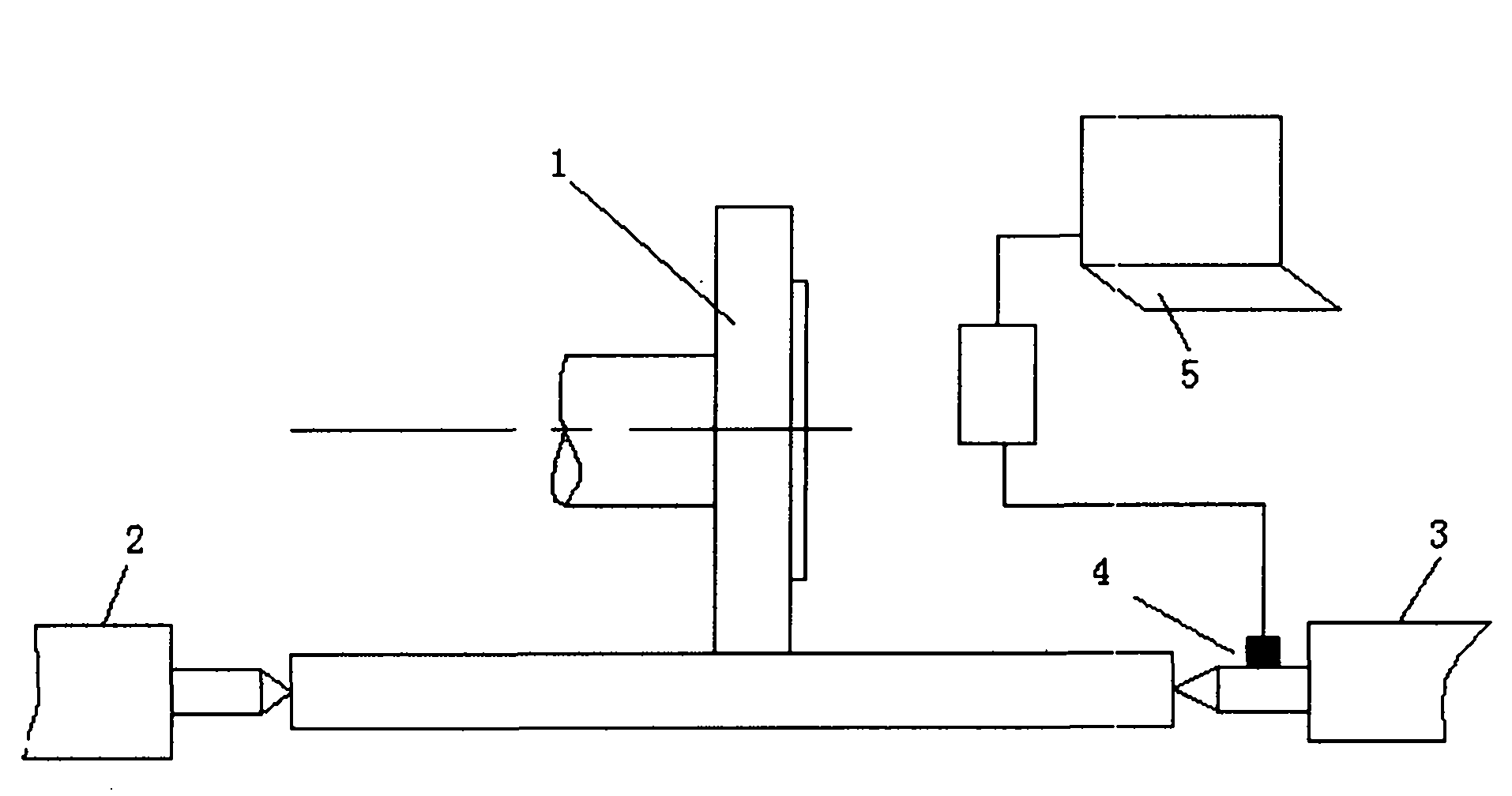

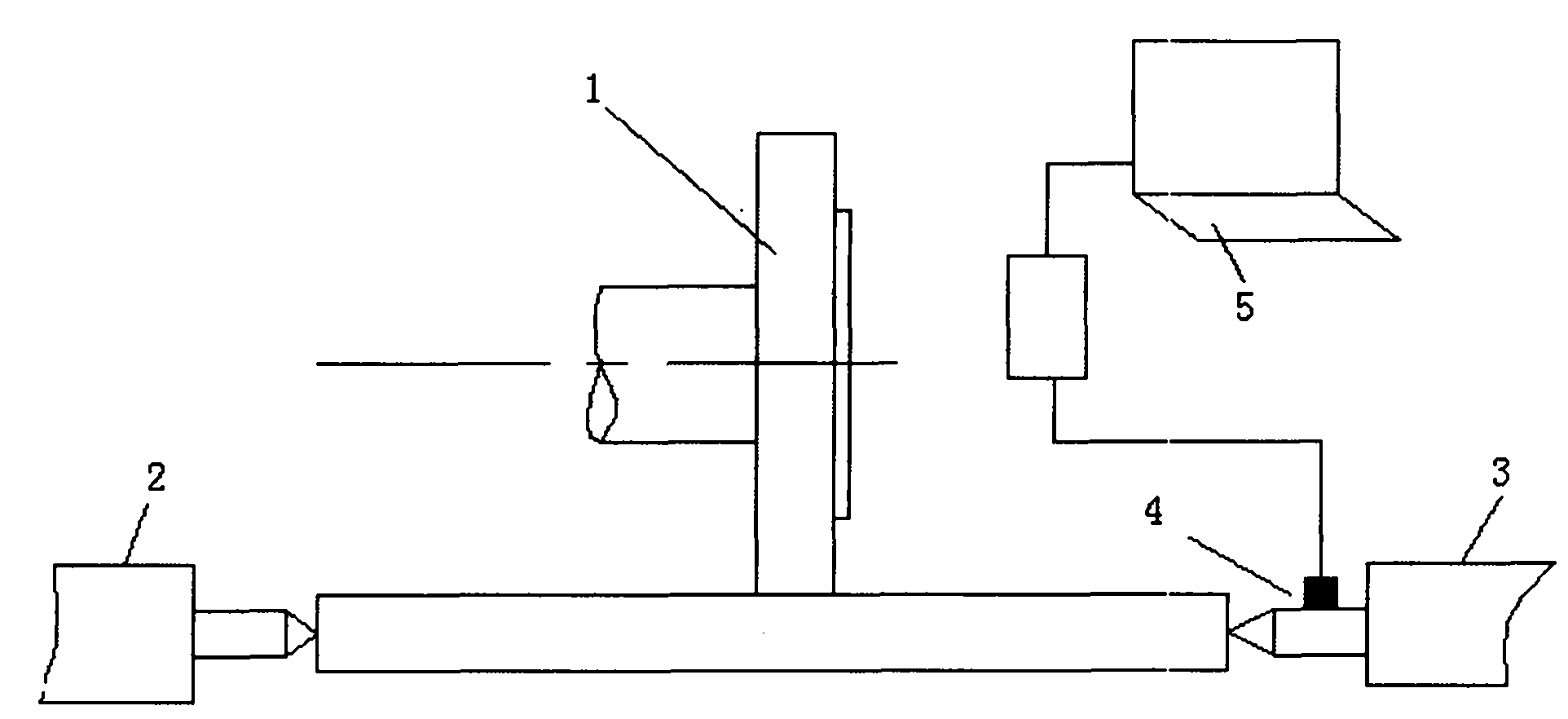

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

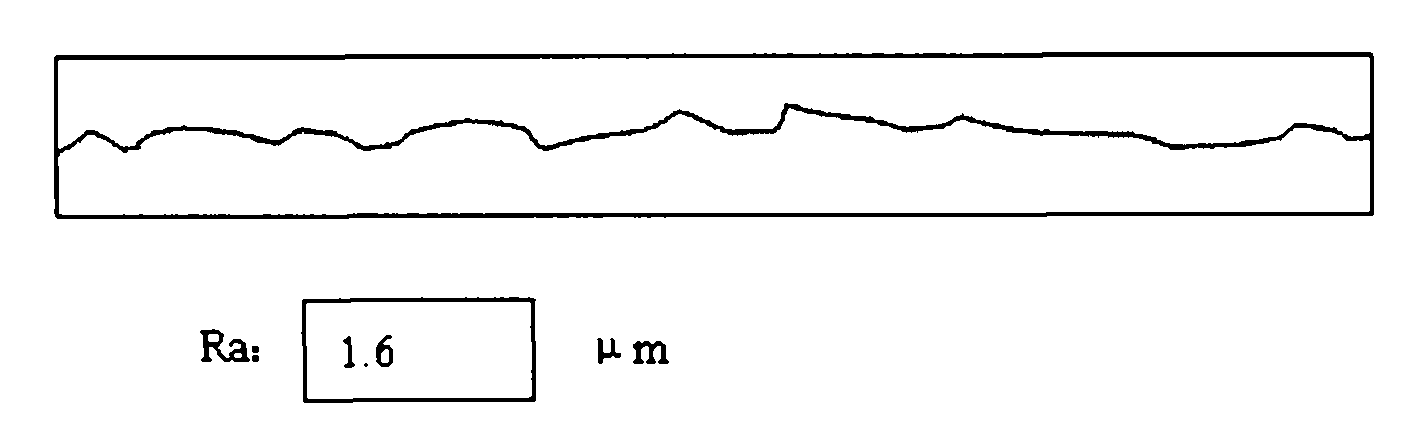

[0017] The method for visual real-time monitoring of the surface quality of the cylindrical grinding workpiece of the present invention, during the grinding process of the workpiece, the elastic contact between the grinding wheel and the workpiece, the rupture of the grinding wheel adhesive, the collapse of the grinding wheel abrasive grains, the friction between the grinding wheel abrasive grains and the workpiece, and the cracks on the surface of the workpiece can emit elastic waves. These factors are closely related to the workpiece material, grinding conditions, and the state of the grinding wheel surface. The change of these factors will inevitably cause changes in the amplitude of the acoustic emission signal, which allows us to judge the grinding state by detecting the change of the acoustic emission signal. The change range of AE signal is prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com