Oligomerization bioactivity factor combination, use method and application thereof

A bioactive factor and composition technology, applied in botany equipment and methods, horticultural methods, chemicals for biological control, etc., can solve the problems of affecting the normal yield of plants, improper composition ratio, prone to lodging, etc. , to achieve the effect of promoting absorption and transportation, safe use, and delaying plant aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

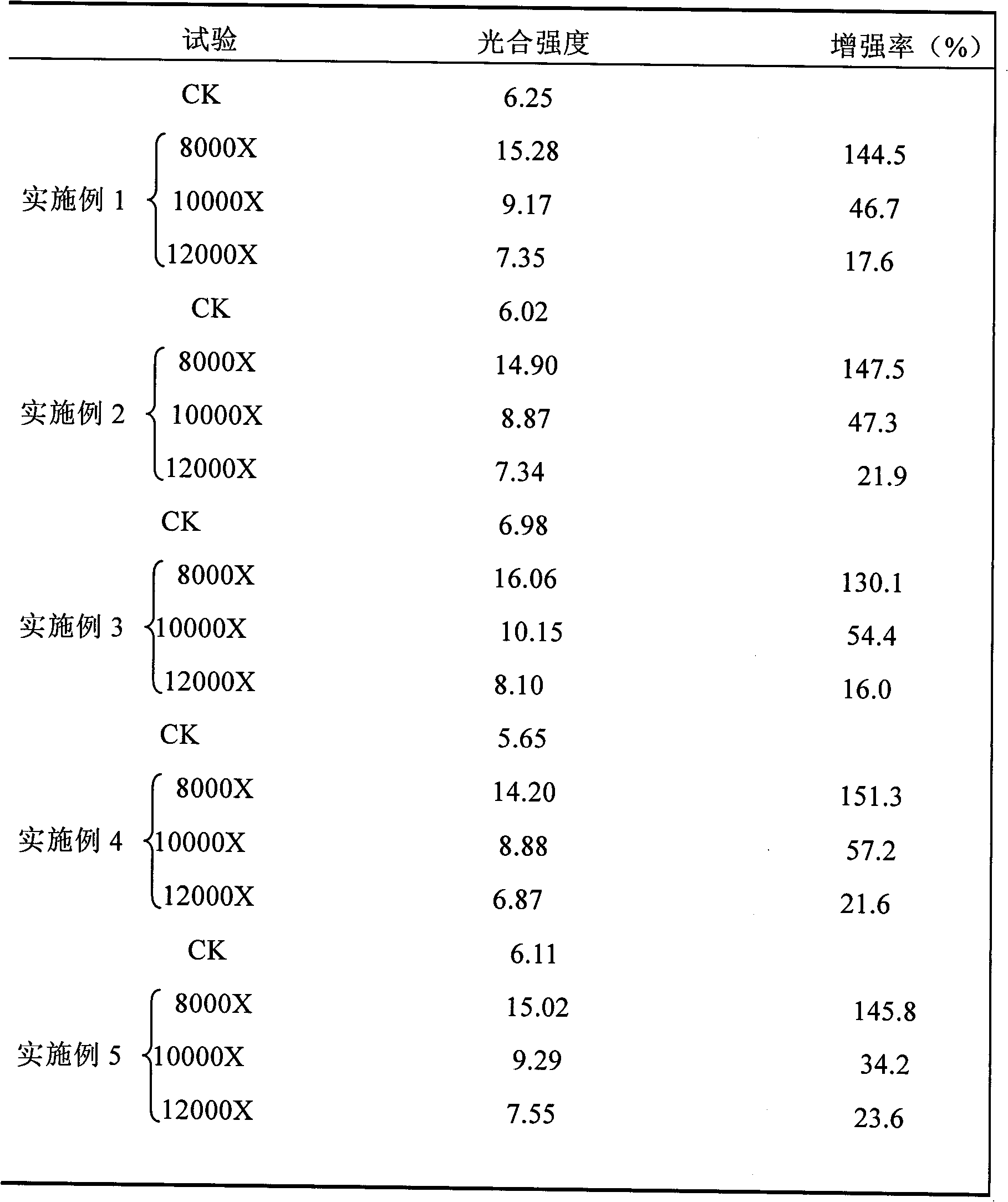

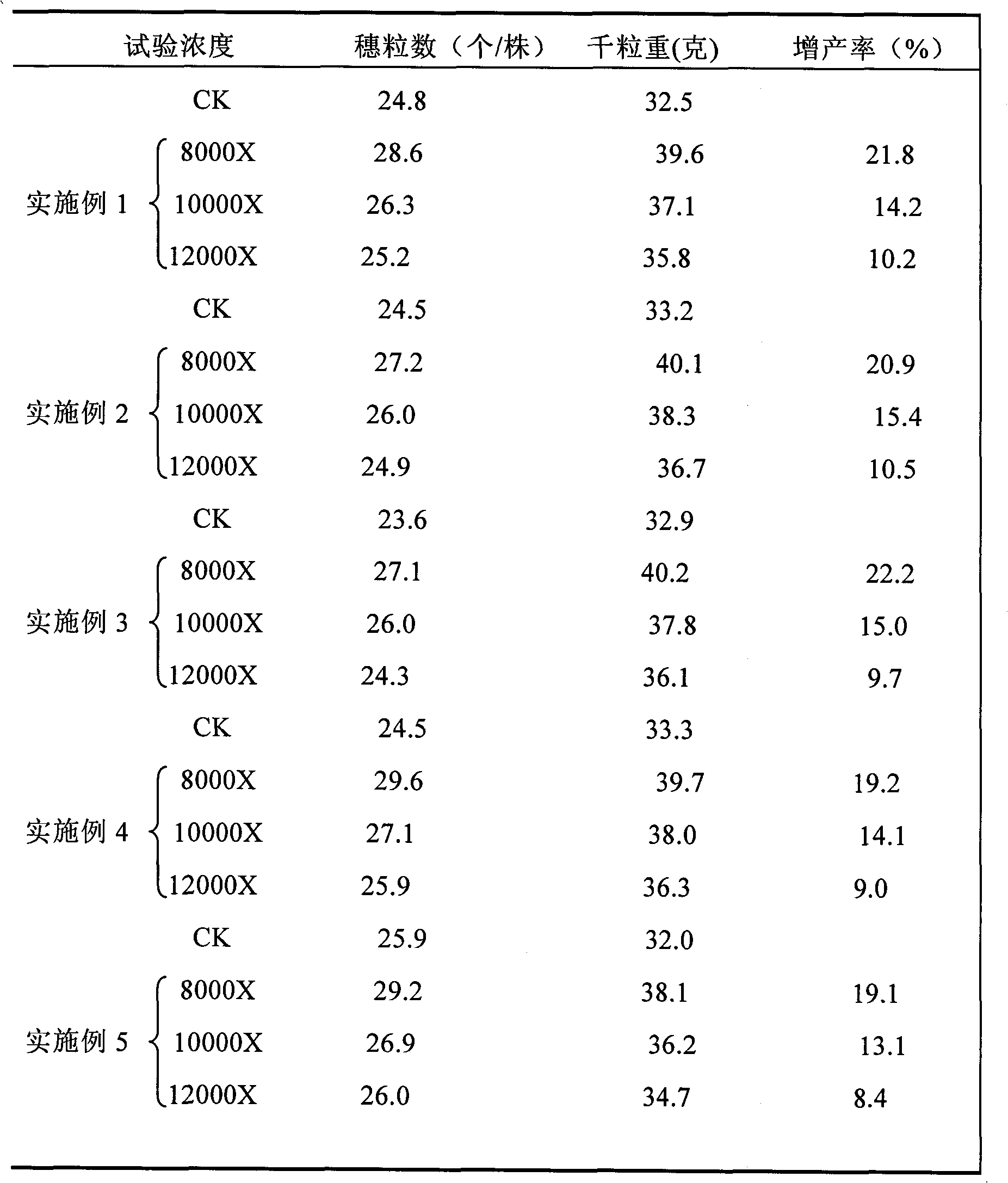

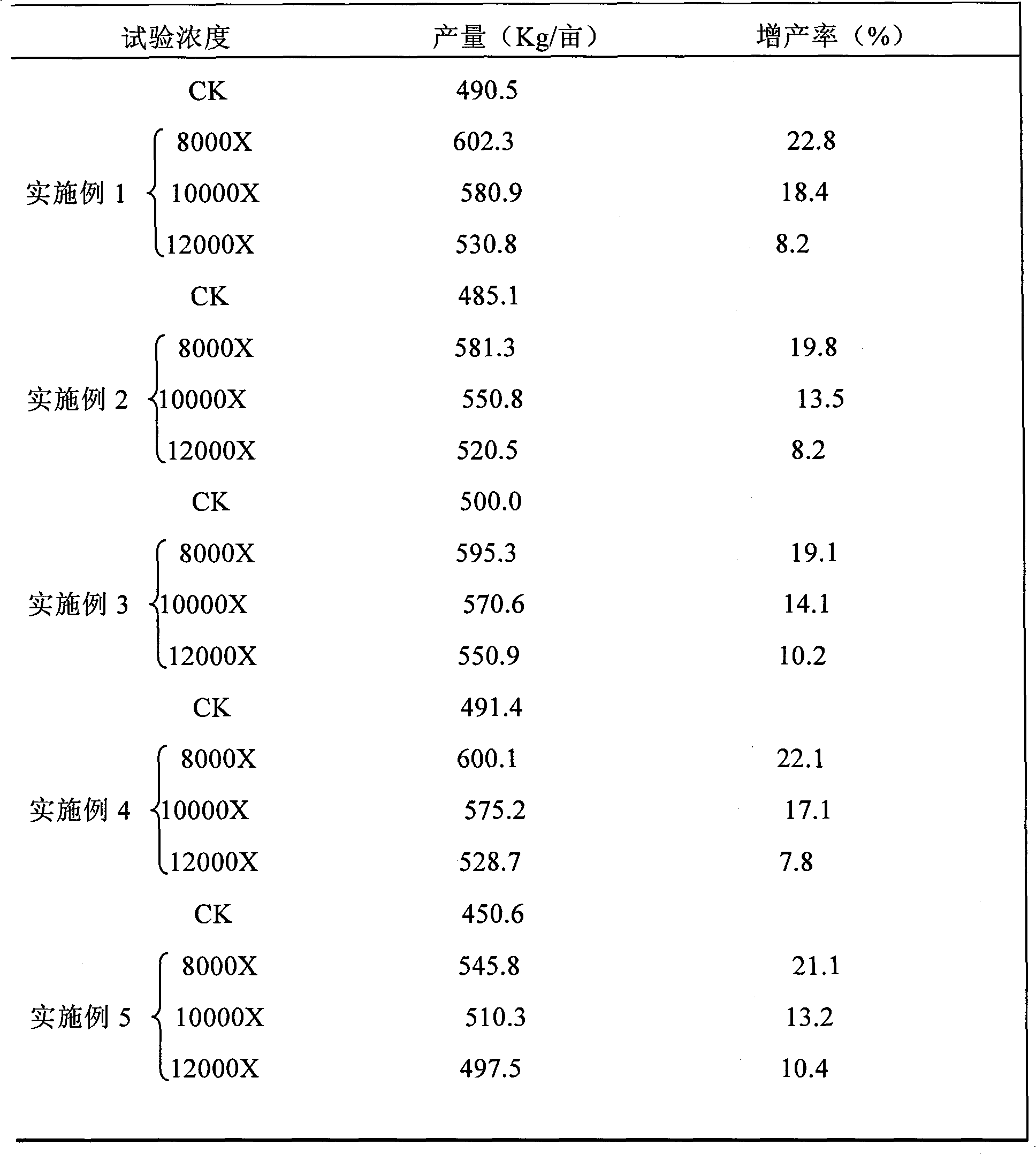

Examples

Embodiment 1

[0036] Weigh raw materials (grams) according to the following weights:

[0037] Take oligomeric acid potassium 500, oligosaccharide phospholipid 400, polypeptide 99, polyamine 0.1, indole acetic acid 0.2, paclobutrazol 0.5, boric acid 0.2.

[0038] 1 kg of product composition powder preparation method: get 500 grams of potassium oligoacid, 400 grams of oligosaccharide phospholipid, 99 grams of polypeptide, 0.1 gram of polyamine, 0.2 gram of indole acetic acid, 0.5 gram of paclobutrazol, and 0.2 gram of boric acid into a container , mix thoroughly in the container, and seal the package with aluminum foil products.

[0039] Method of use: Take 4 grams of the above-mentioned composition powder, dissolve it in 45 kilograms of water to make an aqueous solution, and spray the above-mentioned aqueous solution evenly to an acre of rice during the full earing stage of rice. The composition amount of 4 grams per mu is sprayed once.

[0040] Potassium oligomeric acid was selected from ...

Embodiment 2

[0044] Weigh raw materials (grams) according to the following weights:

[0045] Potassium oligomeric acid 450, oligosaccharide phospholipid 480, polypeptide 30, boric acid 10, indole acetic acid 1, salicylic acid 5, starch 24.

[0046] 1 kg of product composition granules preparation method: get 450 grams of potassium oligoacid, 480 grams of oligosaccharide phospholipid, 30 grams of polypeptide, 10 grams of boric acid, 1 gram of indole acetic acid, 5 grams of salicylic acid, and 24 grams of starch into In the container, mix well in the container, put it into a granulator to granulate, and seal it with aluminum foil products.

[0047] Usage method: take 3 grams of the above-mentioned composition granule, dissolve it in 50 kg of water to make an aqueous solution, and spray the above-mentioned aqueous solution evenly to one mu of wheat at the full earing stage of wheat.

[0048] Potassium oligomeric acid is selected from the degradation products of plant glucan and the product f...

Embodiment 3

[0052] Weigh raw materials (grams) according to the following weights:

[0053] Potassium oligomeric acid 460, oligosaccharide phospholipid 440, polypeptide 60, salicylic acid 10, citric acid 20, zinc stearate 10.

[0054] 1 kg product composition tablet preparation method: take 460 grams of potassium oligosaccharide, 440 grams of oligosaccharide phospholipid, 60 grams of polypeptide, 10 grams of salicylic acid, 20 grams of citric acid, and 10 grams of zinc stearate into a container , mixed evenly, placed in a tablet machine for tableting, and the product is sealed and packaged.

[0055] Usage method: take 5 grams of the above-mentioned composition tablet, dissolve in 45 kilograms of water to make an aqueous solution, and spray the above-mentioned aqueous solution evenly to one mu of wheat at the full ear stage of wheat.

[0056] Potassium oligomeric acid is selected from the degradation product of microbial dextran, which is combined with potassium hydroxide.

[0057] The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com