Biological organic mineral fertilizer and processing method thereof

A technology of organic mineral fertilizer and processing method, which is applied in the directions of organic fertilizer, animal carcass fertilizer, fertilization device, etc. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

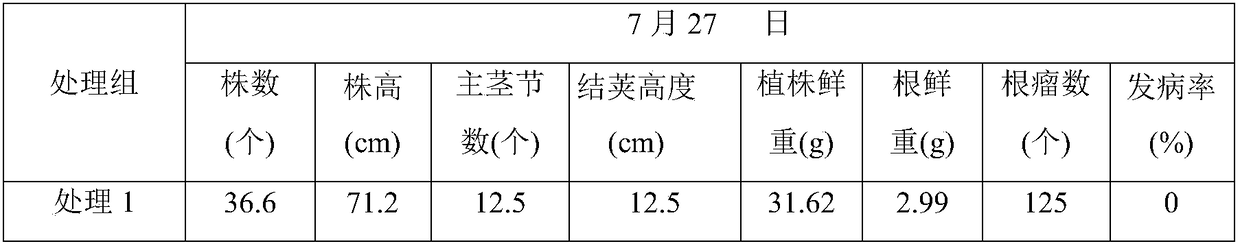

[0042] The processing method of embodiment 1. granular bio-organic mineral fertilizer.

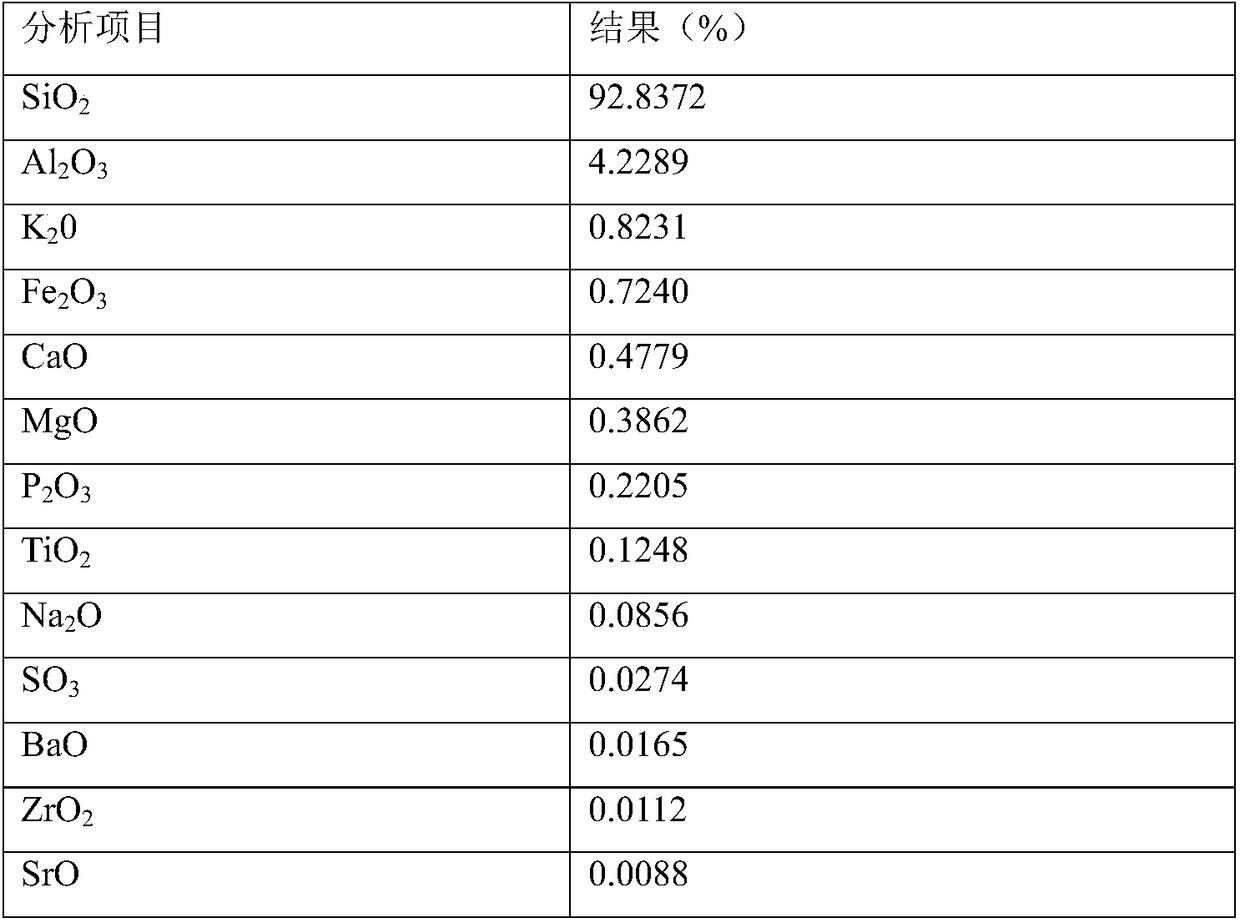

[0043] 1) Take 30kg of diatom shale and 15kg of volcanic rock and grind them into 2000-mesh and 200-mesh powder respectively by Raymond milling, and then calcinate at 600-800°C in a rotary calciner to obtain a mineral powder mixture.

[0044] 2) Quick-frozen chicken racks, duck racks, and minced pork, totaling 47kg, were crushed with frozen meat and minced meat into 300-mesh minced meat, mixed with 5kg lignite humic acid and 2kg 200-mesh soybean powder, and then steamed The autoclave is sterilized at 140°C and 0.260MPa for 40 minutes to form an organic matter mixture.

[0045] 3) Take 9kg of soybeans, put them into a vulcanization tank, sterilize them at 140°C and 0.260MPa for 30 minutes, and then grind them into mud with a pulverizer; add 1kg of subtilis with a live bacteria content of 20 billion / g to it The Bacillus bacteria powder is stirred and mixed, fermented at 24° C. for 2 days, a...

Embodiment 2

[0047]The processing method of embodiment 2. granular bio-organic mineral fertilizers.

[0048] 1) Take 50kg of diatom shale and 5kg of volcanic rock and grind them into powders of 2000 mesh and 200 mesh respectively by Raymond milling, and then calcinate at a low temperature of 600-800°C in a rotary calciner to obtain a mineral powder mixture.

[0049] 2) Quick-frozen chicken racks, duck racks, and minced pork, totaling 25kg, are crushed with frozen meat and minced meat into 300-mesh minced meat, mixed with 13kg of lignite humic acid and 2kg of 200-mesh soybean powder, and then steamed The autoclave is sterilized at 140°C and 0.260MPa for 40 minutes to form an organic matter mixture.

[0050] 3) Take 9kg of soybeans, put them into a vulcanization tank, sterilize them at 140°C and 0.260MPa for 30 minutes, and then grind them into mud with a pulverizer; add 1kg of subtilis with a live bacteria content of 20 billion / g to it The Bacillus bacteria powder is stirred and mixed, fer...

Embodiment 3

[0052] The processing method of embodiment 3. granular bio-organic mineral fertilizers.

[0053] 1) Take 45kg of diatom shale and 10kg of volcanic rock and make them into 2000 mesh and 200 mesh powder respectively by Raymond milling, and then calcinate at 600-800°C in a rotary calciner to obtain a mineral powder mixture.

[0054] 2) Quick-frozen chicken racks, duck racks, and minced pork, totaling 30kg, were crushed with frozen meat and minced meat into 300-mesh minced meat, mixed with 10kg lignite humic acid and 3kg 200-mesh soybean powder, and then steamed The autoclave is sterilized at 140°C and 0.260MPa for 40 minutes to form an organic matter mixture.

[0055] 3) Take 9kg of soybeans, put them into a vulcanization tank, sterilize them at 140°C and 0.260MPa for 30 minutes, and then grind them into mud with a pulverizer; add 1kg of subtilis with a live bacteria content of 20 billion / g to it The Bacillus bacteria powder is stirred and mixed, fermented at 24° C. for 5 days, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com