Color film base plate and manufacturing method thereof

A technology of a color film substrate and a manufacturing method, which is applied in the field of liquid crystal display and its manufacturing, can solve the problems of reduced voltage retention rate, reduced contrast ratio, and abnormal black display, so as to improve voltage retention ratio and contrast ratio, improve quality, and avoid leakage The effect of current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

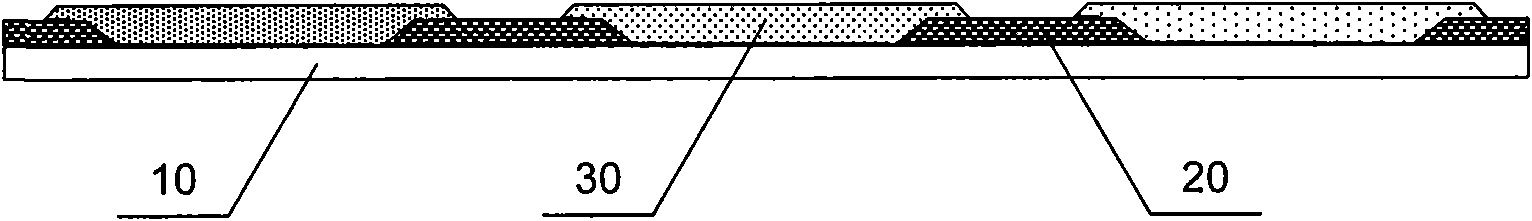

[0039] figure 1 It is a schematic structural diagram of the first embodiment of the color filter substrate of the present invention. Such as figure 1 As shown, the color filter substrate of this embodiment includes a substrate 10, a first black matrix 20, a color resin 30, a protective layer 40, a second black matrix 50, and a common electrode 60, wherein the first black matrix 20 and the color resin 30 are formed on On the substrate 10, the colored resin 30 includes three colors: red resin, blue resin and green resin, and the colored resin 30 of the three colors is sequentially formed between the first black matrix 20; the protective layer 40 is formed on the first black matrix 20 and the color resin 30 and cover the entire substrate 10; the second black matrix 50 is arranged in the groove opened on the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com