Multi-cavity steel tube concrete superposed column and preparation method thereof

A technology of concrete-filled steel pipe columns and concrete-filled steel pipes, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of weakening the advantages of steel pipe concrete inner columns, reducing the bearing capacity of steel pipe concrete composite columns, and reducing the useable area of buildings, etc., to achieve The building functions are fully reasonable, the space utilization rate is improved, and the effect of earthquake resistance is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

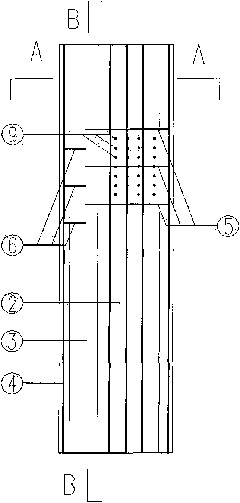

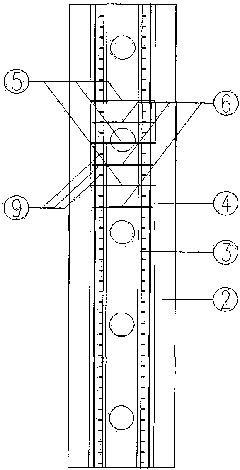

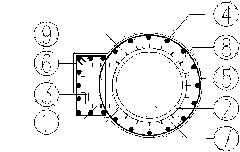

[0032] Schematic diagram of structural steel and reinforcement in a multi-cavity steel tube concrete composite column whose cross-section shape is a table tennis racket Figure 1 ~ Figure 3 shown. In this embodiment, a multi-cavity steel pipe 1 composed of a steel pipe 2 and a steel plate 3 is combined with poured concrete and a reinforced concrete outer column 8. The two strip-shaped steel plates in this embodiment are welded at a vertical angle to the longitudinal edge. And the third steel plate is welded on the longitudinal side to form a U-shaped groove, and the U-shaped groove is welded to the circular cross-section steel pipe in the longitudinal direction to form the multi-cavity steel pipe 1 in the steel tube concrete inner column. The steel pipe 2 and the steel plate 3 are reserved with holes to facilitate concrete pouring, and the steel plate 3 also has holes for binding hoops. Weld rivets 9 on the outer wall of the multi-cavity steel pipe 1, and then bind the longit...

Embodiment 2

[0043] The structure of this embodiment is basically the same as that of Embodiment 1, the only difference is that the cross-sectional shape of the multi-cavity steel pipe is different, such as Figure 4 ~ Figure 6 As shown, the multi-cavity steel pipe in this embodiment is composed of two strip-shaped steel plates and two steel pipes whose cross-sectional shape is an equilateral right triangle. The two long sides of the two strip-shaped steel plates are respectively welded to the longitudinal right-angled sides and the longitudinal acute-angled sides of the two equilateral right-angled triangular cross-section steel pipes, and the two long sides of the other strip-shaped steel plate are respectively welded to the longitudinal acute-angled sides of the two equilateral right-angled triangular cross-section steel pipes. The sides are welded at right angles to the longitudinal side, and the two strip steel plates are parallel to each other and perpendicular to the steel plates of ...

Embodiment 3

[0045] The structure of this embodiment is basically the same as that of Embodiment 1, the only difference is that the cross-sectional shape of the multi-cavity steel pipe is different, such as Figure 7 ~ Figure 9 As shown, the multi-cavity steel pipe in this embodiment is composed of two strip-shaped steel plates and two steel pipes with the same size and rectangular cross-section shape, and the two long sides of the strip-shaped steel plates are respectively welded to the longitudinal right-angle sides of the two rectangular cross-section steel pipes. , the two long sides of another strip steel plate are respectively welded to the opposite sides of the longitudinal right-angled sides of the two welded rectangular cross-section steel pipes, and the surface formed by the two welded right-angled sides on each rectangular cross-section steel pipe is perpendicular to the two strip steel plates In this way, a multi-cavity steel pipe with a diamond-shaped outer contour is formed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com