Production equipment for comprehensively utilizing renewable energy resources of waste and old plastics, tires and waste engine oil

A technology of waste plastics and renewable energy, applied in the direction of mechanical equipment, solid waste removal, liquid hydrocarbon mixture preparation, etc., can solve the problems of single utilization and development, only discharge to the sky, waste of reusable resources, etc., to achieve Eliminate secondary pollution, low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

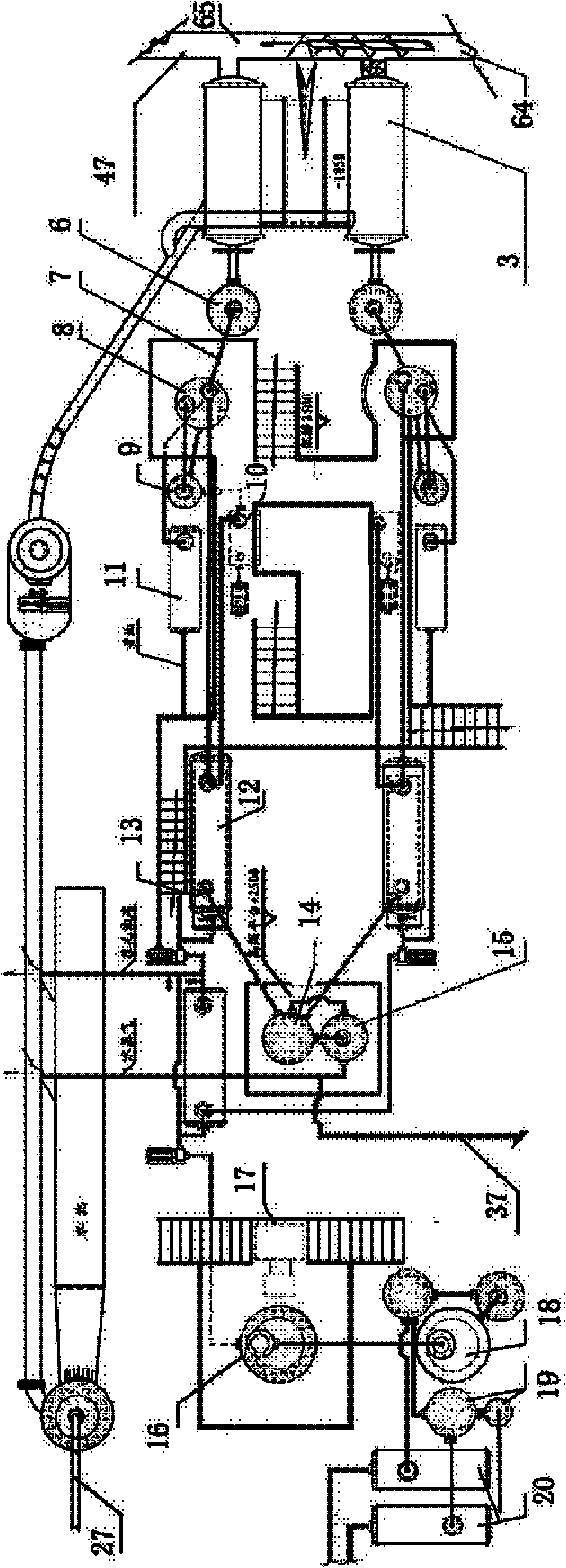

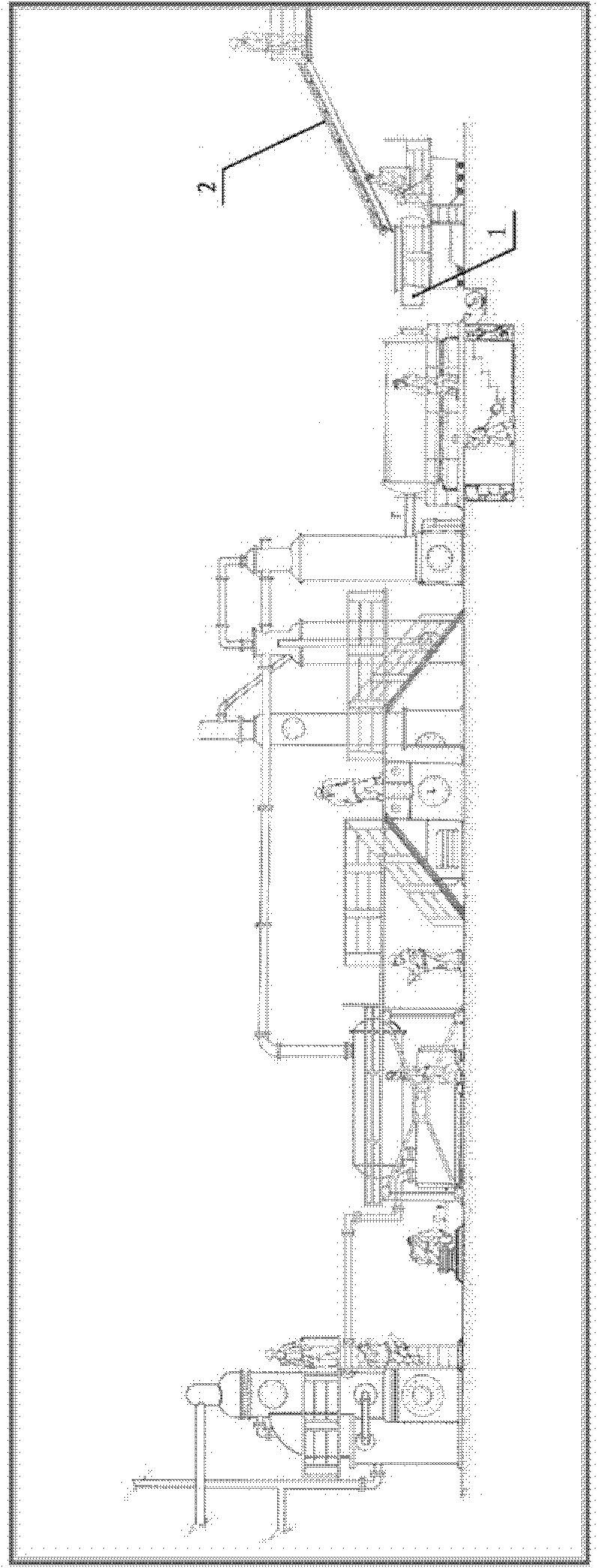

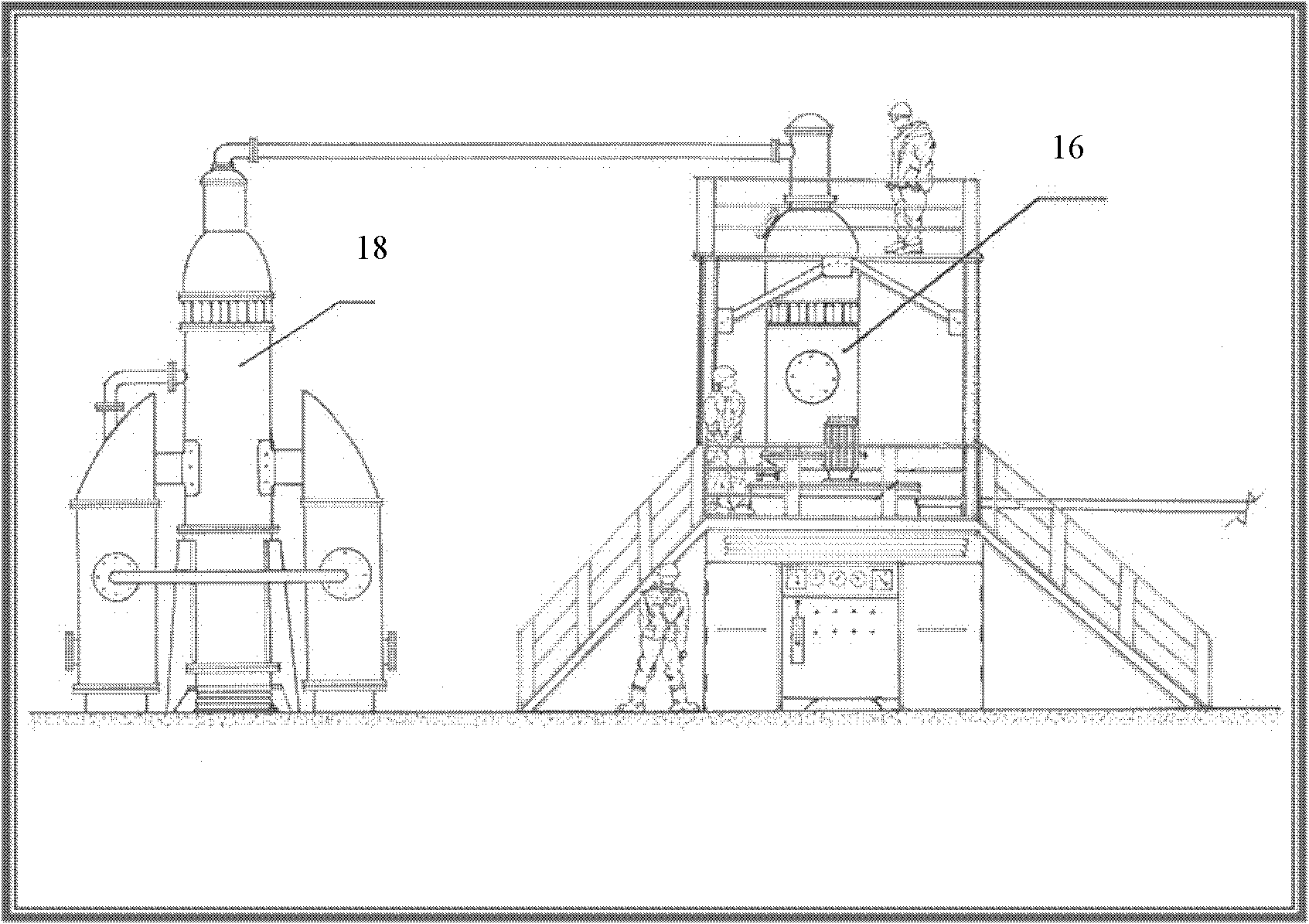

[0029] Such as Figure 1 to Figure 10 As shown, the comprehensive utilization of renewable energy production equipment for waste plastics, tires, and waste engine oil includes the main equipment, the second-level device, the third-level device, the cracking furnace tail gas treatment environmental protection system, and the reuse of combustible gas for power generation. system, hot gas recovery system, and environmentally friendly high-energy low-sulfur coal system.

[0030] The main equipment described therein includes: starting from the conveyor belt 2, the petroleum product waste is transported to the pneumatic automatic feeder 1 moved by the rail, and the raw material is pushed into the cracking catalytic furnace 3 for cracking and catalysis to obtain an oil-gas mixture. The catalytic furnace is equipped with a reactor 5 with scraper 4 which is automatically and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com