Nano calcium carbonate strengthened microcrystal polypropylene composite material synthesized by supercritical fluid rapid diffusion method

A nano-composite material and nano-calcium carbonate technology, applied in the production of bulk chemicals, etc., can solve the problems of difficult material performance stability, unfavorable environmental protection production, etc., and achieve the effect of reducing the size of spherulites, improving optical properties, and reducing shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

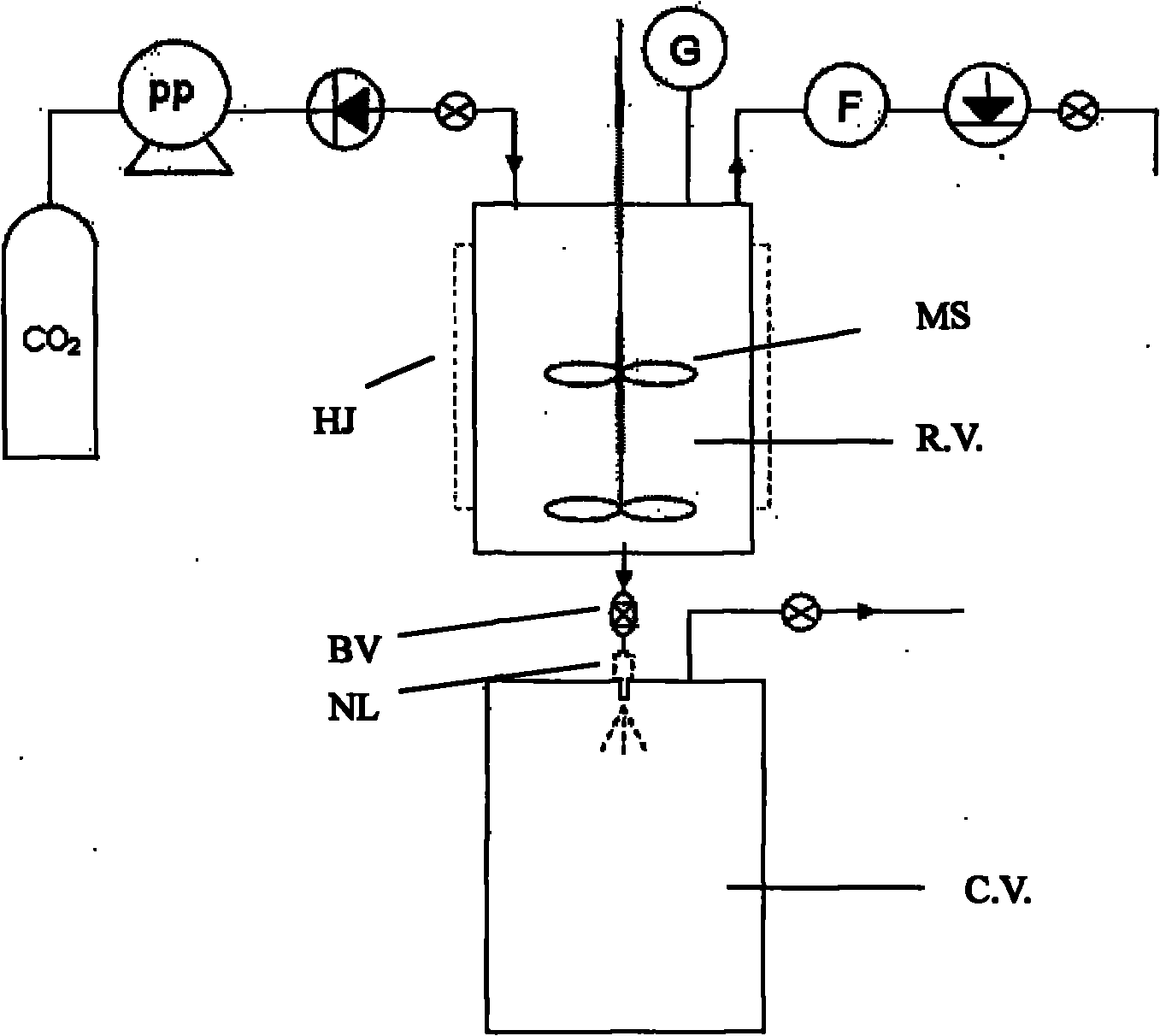

[0005] The supercritical carbon dioxide rapid diffusion process is used in this invention as the preparation process of the nanocomposite PP material. This system uses a novel vertical design of the reactor collection tank (as shown in the figure), which is conducive to the mass transfer of materials and reduces the chance of clogging the nozzle. The working process of the whole system can be summarized as: CO with an initial pressure of 5MPa 2 (CO 2 The pressure in the cylinder) is injected into the reaction kettle through a syringe pump, and the heating device covering the reaction kettle heats the initial mixing system of nano-calcium carbonate and PP in the reaction kettle, and the electromagnetic stirrer quickly stirs the entire material system , when the pressure and temperature of the system reach a predetermined value, this value is set to 25MPa and 200°C in this invention. After mixing under this condition for 1 hour, open the ball valve, so that the entire material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com