Reversible hydrogen adsorption and desorption method using piperidine as media and device

A technology for absorbing and desorbing hydrogen and piperidine, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of low dehydrogenation conversion rate, easy carbon deposition on catalysts, and high dehydrogenation temperature, and achieves lower reaction temperature and operation. Convenience and system simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Preparation of hydrogen storage alloy powder

[0036] According to the atomic ratio of the metal elements in the alloys in Table 1, weigh the corresponding metals and put them into the crucible. For hydrogen storage alloys containing calcium and magnesium, put them in an argon-protected tube furnace, raise the temperature to 800°C under the protection of argon, keep at 800°C for 2 hours and then cool to room temperature to obtain the corresponding bulk calcium-based or magnesium-based alloys. Broken by mechanical crushing method, the particles with a particle size of less than 2 mm were obtained by screening, placed in a stainless steel reactor, heated to 350 ° C, and vacuumed to a reactor pressure of 10 -3 Below Torr, then hydrogenation is added and the pressure is increased to 40 atmospheres for hydrogenation. When the hydrogen pressure in the reactor no longer drops, the temperature is raised to 450°C for dehydrogenation under reduced pressure. After ...

Embodiment 2

[0041] Embodiment 2: surface treatment of hydrogen storage alloy

[0042] At room temperature, 10 grams of some hydrogen storage alloy powders in Example 1 are placed in 200 milliliters and the concentration is 0.01-0.5M L -1 Soak in hydrochloric acid, oxalic acid or glacial acetic acid solution at room temperature for 0.5~5h, or place in 200ml concentration of 2~6M L -1 Soak in NaOH or KOH solution at 50-90°C for 0.5-5h, take it out by filtration, wash and filter with deionized water, and dry in vacuum at 70-90°C for 6-12h. The surface treatment conditions are listed in the table 2.

[0043] Table 2 Surface treatment process conditions of hydrogen storage alloys

[0044]

Embodiment 3

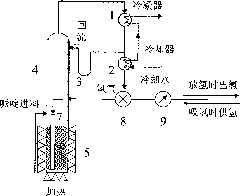

[0045] Embodiment 3: The device of pyridine / piperidine hydrogen absorption and desorption

[0046] The schematic diagram of the device for pyridine / piperidine hydrogen absorption and desorption described in the present invention is as follows figure 1 As shown, it includes a reactor 4, a condenser 1, a cooler 2 and a reflux device 3; the bottom of the reactor 4 is provided with a catalyst bed 6 for loading a hydrogen storage alloy, and the periphery of the reactor 4 bottom is provided with a heating device 5 for Control the reaction temperature; the middle part of the side of the reactor 4 is provided with a hydrogen inlet and a piperidine feeding port, and the hydrogen inlet is connected to the hydrogen guide pipe 7 and extends into the catalyst bed 6; the top of the reactor 4 is connected to the condenser 1 and the Cooler 2, the pipeline at the outlet of condenser 1 is also connected to the upper part of reactor 4 through reflux device 3, and the outlet of cooler 2 is a hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com