Supported nano gold catalyst for cyclohexane oxidation and preparation method thereof

A catalyst and a supported technology, applied in the field of supported nano-gold catalysts and their preparation, can solve the problems that the performance of the nano-gold catalyst needs to be improved, the activity of the nano-gold catalyst is reduced, and the industrial production is unfavorable, and the catalyst dosage is small, the activity and the selection are achieved. The effect of good performance and high load efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

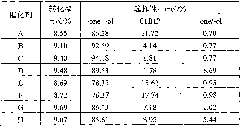

[0017] Preparation of Catalyst A. Take 0.04g chloroauric acid (HAuCl 4 4H 2 O) Dissolve in 100mL deionized water, add 2.00g γ-alumina (γ-Al 2 o 3 ) carrier, stirred and impregnated for 1 h at room temperature, poured off the supernatant, washed the obtained solid twice with deionized water, then soaked with 15 mL of 4M ammonia water for 5 min, filtered, and finally washed twice with deionized water to obtain The solid was dried at 80°C for 10 hours, and then calcined at 300°C for 3 hours to obtain catalyst A, whose composition is shown in Table 1.

Embodiment 2

[0019] Preparation of Catalyst B. 2.50g of γ-alumina (γ-Al 2 o 3 ) with 15mL containing 0.09g cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) aqueous solution at room temperature for 1 hour, then rotary evaporated at 60°C to dryness, dried at 110°C for 2 hours, and calcined at 500°C for 3 hours to obtain a modified alumina carrier. Take 0.04g chloroauric acid (HAuCl 4 4H 2 O) Dissolve in 100mL deionized water, add 2.00g of the above-mentioned modified alumina carrier, stir and impregnate at room temperature for 1h, pour off the supernatant, wash the obtained solid three times with deionized water, and then wash it with 15mL 4M After soaking in ammonia water for 8 minutes, filter, and finally wash twice with deionized water, dry the obtained solid at 100°C for 8 hours, and roast at 300°C for 4 hours to obtain Catalyst B, whose composition is shown in Table 1.

Embodiment 3

[0021] Preparation of Catalyst C. 2.50g of γ-alumina (γ-Al 2 o 3 ) with 15mL containing 0.28g cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) aqueous solution at room temperature for 2 hours, then rotary evaporated to dryness at 50° C., dried at 80° C. for 3 hours, and calcined at 500° C. for 4 hours to obtain a modified alumina carrier. Take 0.04g chloroauric acid (HAuCl 4 4H 2 O) Dissolve in 100mL deionized water, add 2.00g of the above-mentioned modified alumina carrier, stir and impregnate at room temperature for 2h, pour off the supernatant, wash the obtained solid twice with deionized water, and then wash it with 15mL 4M Soak in ammonia water for 7 minutes, filter, and finally wash with deionized water for 3 times, dry the obtained solid at 90°C for 8 hours, and calcinate at 300°C for 4 hours to obtain catalyst C, whose composition is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com