Continuous casting nozzle and production method therefor

A manufacturing method and pouring nozzle technology, applied in the direction of manufacturing tools, casting equipment, casting melt containers, etc., can solve the problems of control, productivity reduction, molten steel cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0177] The invention is applied to tubular refractory structures known as long spouts, which convey molten steel between pots and tundishes used in continuous casting processes.

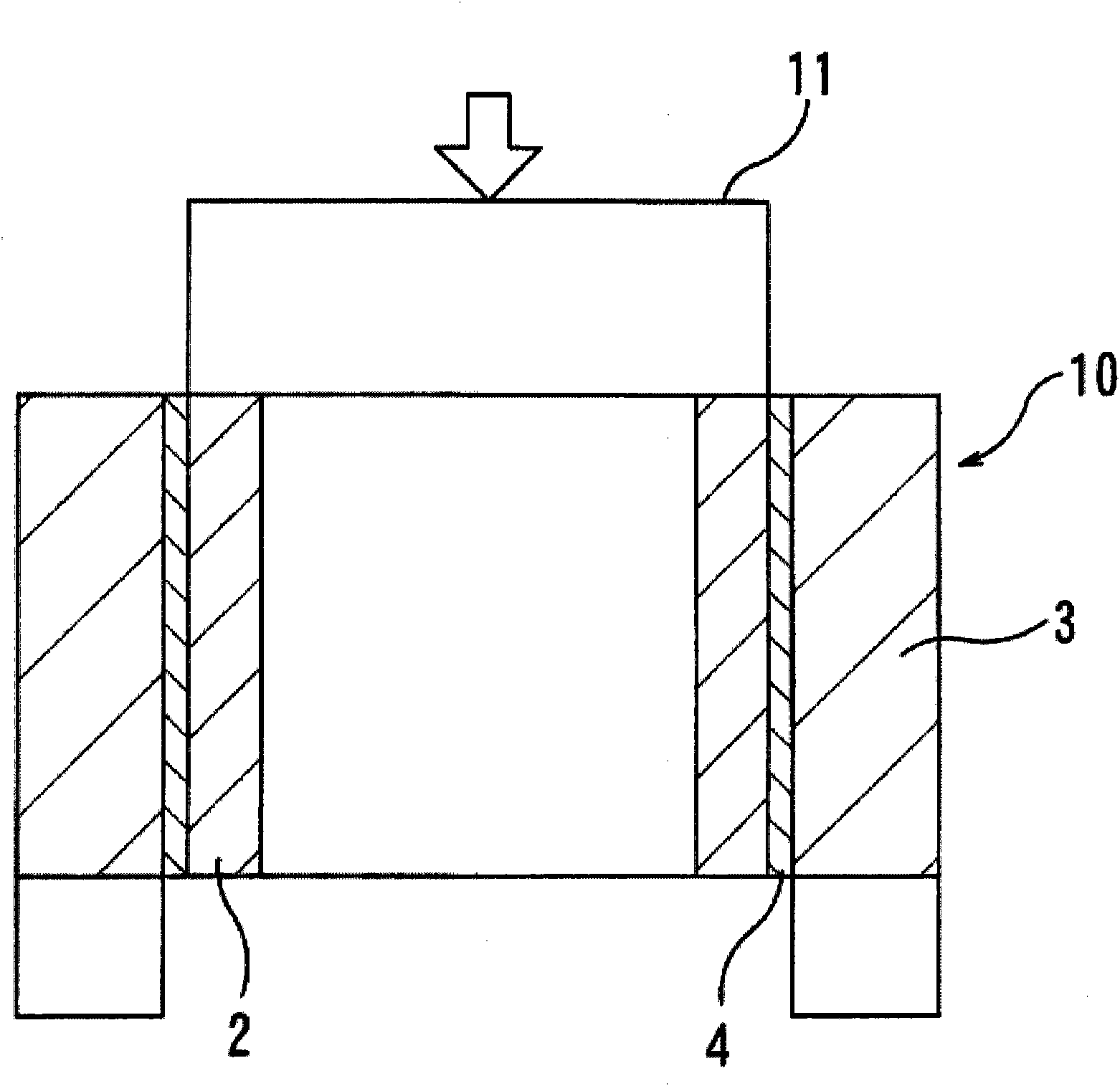

[0178] Such as figure 1 As shown, regarding the material arrangement structure of the long pouring nozzle 1 (inner hole diameter: Φ140mm, outer diameter of the straight shell part: Φ226mm, length 1500mm), as the inner hole side layer 2, a thickness of 10mm is used on all inner hole surfaces MgO-C material (MgO = 77% by mass, C = 19% by mass) with a maximum thermal expansion rate before 1500°C of 1.8% is arranged as the outer peripheral side layer 3 on the part not immersed in molten steel (non-impregnated part side) , Al with a maximum thermal expansion rate of 0.5% before 1500°C is arranged in a thickness of 30 mm 2 o 3 -SiO 2 -C material (Al 2 o 3 =50% by mass, SiO 2 =25% by mass, C=25% by mass), the thickness of the intermediate layer 4 for alleviating the thermal expansion of the inner hol...

Embodiment 7

[0197] In Example 7 and Example 8, a part of the combustible particles were replaced with fire-resistant particles. Sufficient shrinkability and adhesiveness were obtained, and good results were obtained. In Comparative Example 7, although the refractory particles were further increased compared with Example 7, sufficient shrinkability was not obtained, shrinkage cracks were observed in the intermediate layer, and sufficient adhesive strength was not obtained. As a result, even in the pouring test, peeling of the inner hole side layer occurred in the second time.

[0198] Above embodiment is that the present invention is applied to figure 1 example of a long sprue is shown, but is not limited to it, for example can also be applied to figure 2 The tubular refractory structure shown.

[0199] figure 2 Examples of (a), (b) are applied with figure 1 Example of the same long pouring tip, however, figure 2 In the example of (a), the refractory material of the outer layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com