Waterproof stain-resistant rubber sheathed cable and manufacturing method thereof

A water-blocking and rubber-sheathed technology, applied in cable/conductor manufacturing, insulated cables, flexible cables, etc., can solve the problem of radial water blocking, poor oil resistance, poor radial water blocking, and unreasonable structure, etc. problems, to achieve the effect of superior radial water blocking performance, good heat aging resistance, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

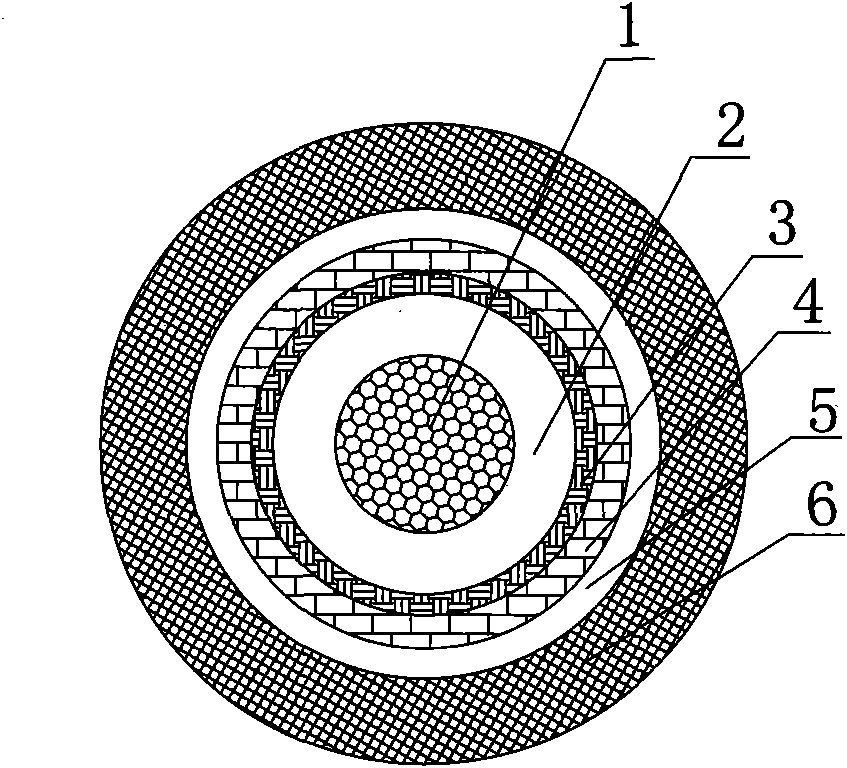

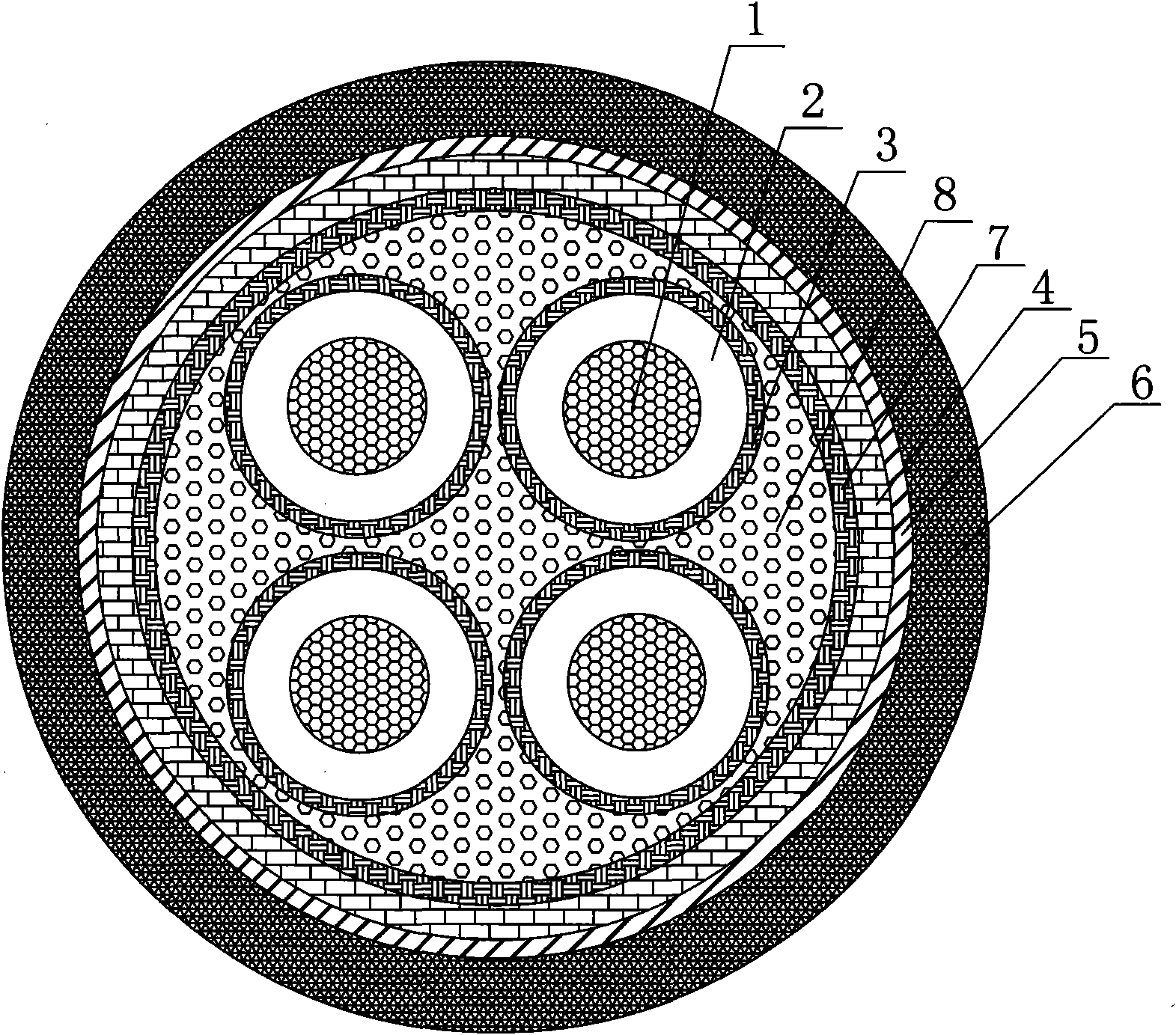

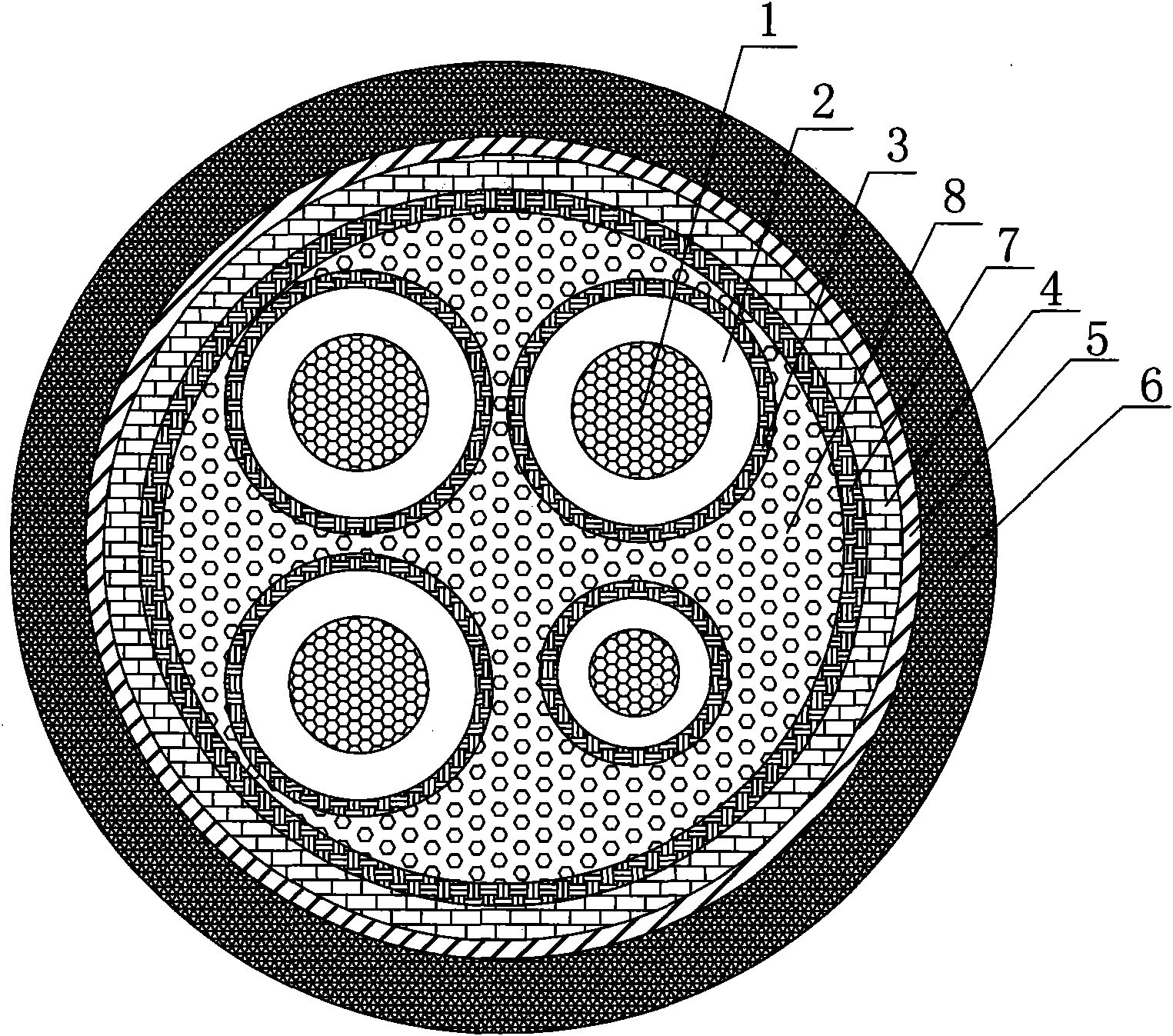

[0035] Example: The manufacturing specification is ZSW-ERX64-0.6 / 1KV 3×50+1×25 (3×50+1×25 means 3 circular inner cores, and the nominal cross-sectional area of each circular inner core is 50mm 2 , a nominal cross-sectional area of 25mm 2 The method of water-blocking and pollution-resistant rubber-sheathed cables with a circular inner core), the specific steps are as follows:

[0036] 1) Wire drawing: purchase Φ8.0mm electrolytic copper rod, and draw from Φ8.0mm electrolytic copper rod to Φ0.30mm copper wire;

[0037] 2) Stranding: 50mm 2 The inner conductor adopts a stranded structure of 10 / 70 / 0.30mm, that is, 70 bundled wires of 0.30mm, 10 strands, and 70 strands of 0.30mm for each strand; 25mm 2 The inner conductor adopts a stranded structure of 10 / 35 / 0.30mm, that is, 35 bundles of 0.30mm, 10 strands, and 35 strands of 0.30mm for each strand. The resistance meets the requirements of the national standard: GB / T3956-2008;

[0038] 3) Extruded ethylene propylene rubber i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com