Liquid storage tank pressurized urea solution metering injection system for diesel vehicle

A technology of injection system and liquid storage tank, which is applied in exhaust gas treatment, mechanical equipment, engine components, etc., can solve the problems of poor reliability, complex structure and high cost, and achieve a guaranteed supply, simple principle and complete safety measures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

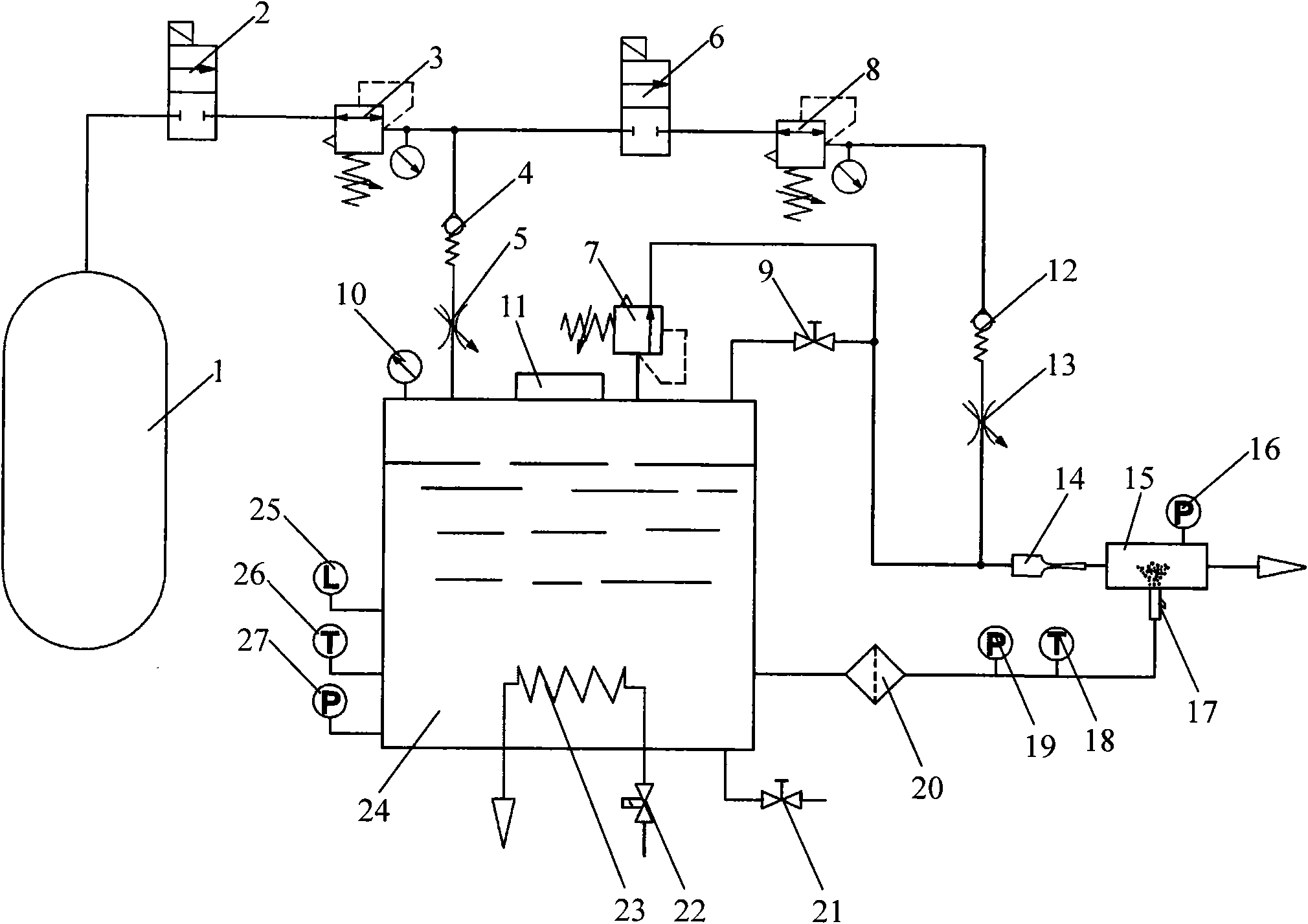

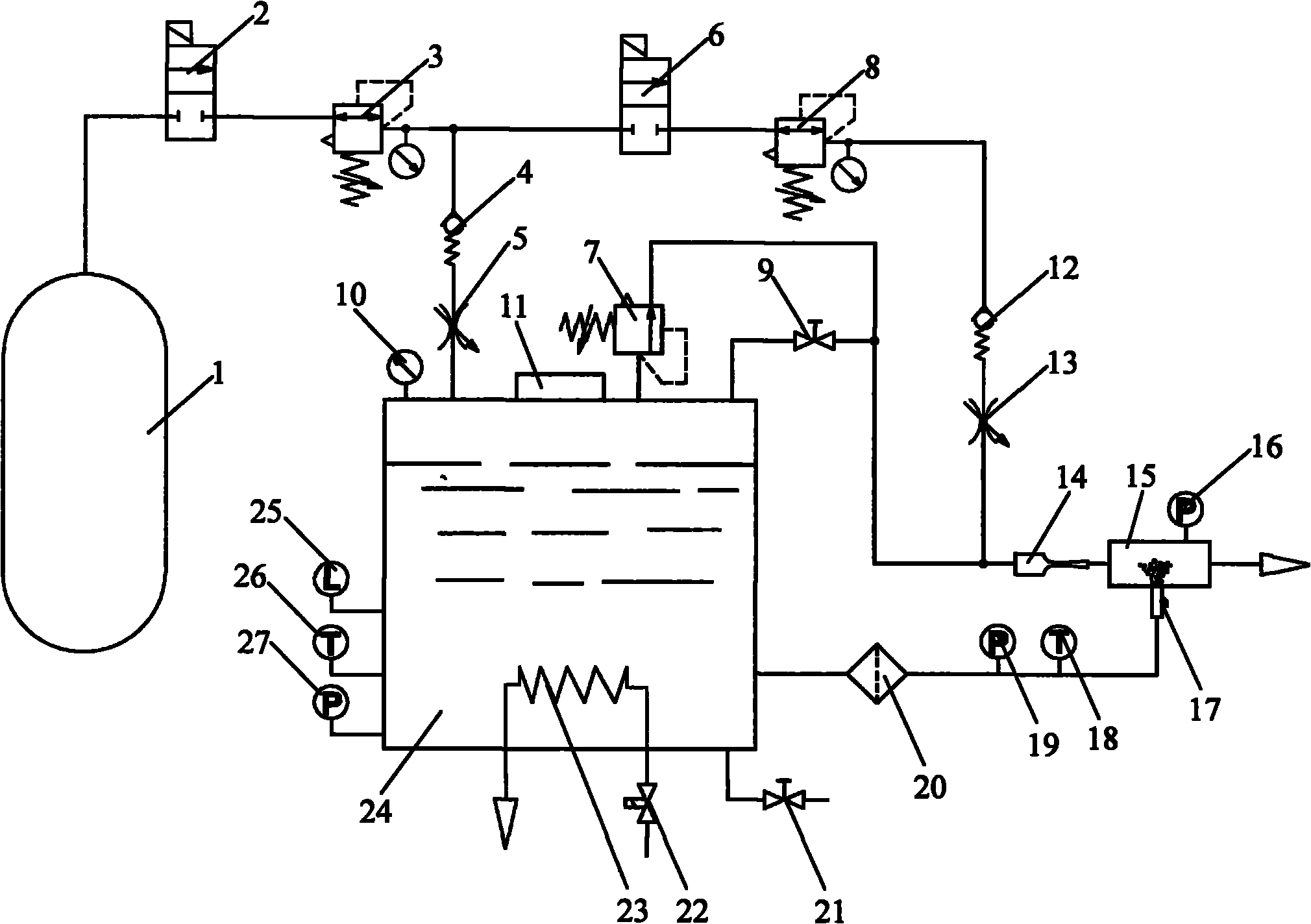

[0032] See figure 1 As shown, the liquid storage tank pressurized urea solution metering injection system for diesel vehicles of the present invention includes a liquid storage tank 24, an injector 17, a gas storage tank 1, a first electromagnetic valve 2, a second electromagnetic valve 6, and a Venturi tube 14. A mixer 15 and a control device (not shown), the mixer 15 includes an inlet and an outlet opposite to the inlet and communicated with the inlet, the injector 17 is installed on the side of the mixer 15 In the side wall, the gas storage tank 1 is respectively gas-connected to the second solenoid valve 6 and the liquid storage tank 24 through the first solenoid valve 2, and the liquid storage tank 24 is connected to the injector 17 liquid The gas path of the second solenoid valve 6 is connected to the venturi tube 14, the venturi tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com