Three-dimensional simulation test device for oil extraction by injecting multielement hot fluid

A multi-component thermal fluid and simulation test technology, which is applied in the field of three-dimensional simulation test equipment for multi-component thermal fluid injection in reservoirs, can solve the problems of no configuration, cumbersome operation process, and steam channeling after injection, and achieve the effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

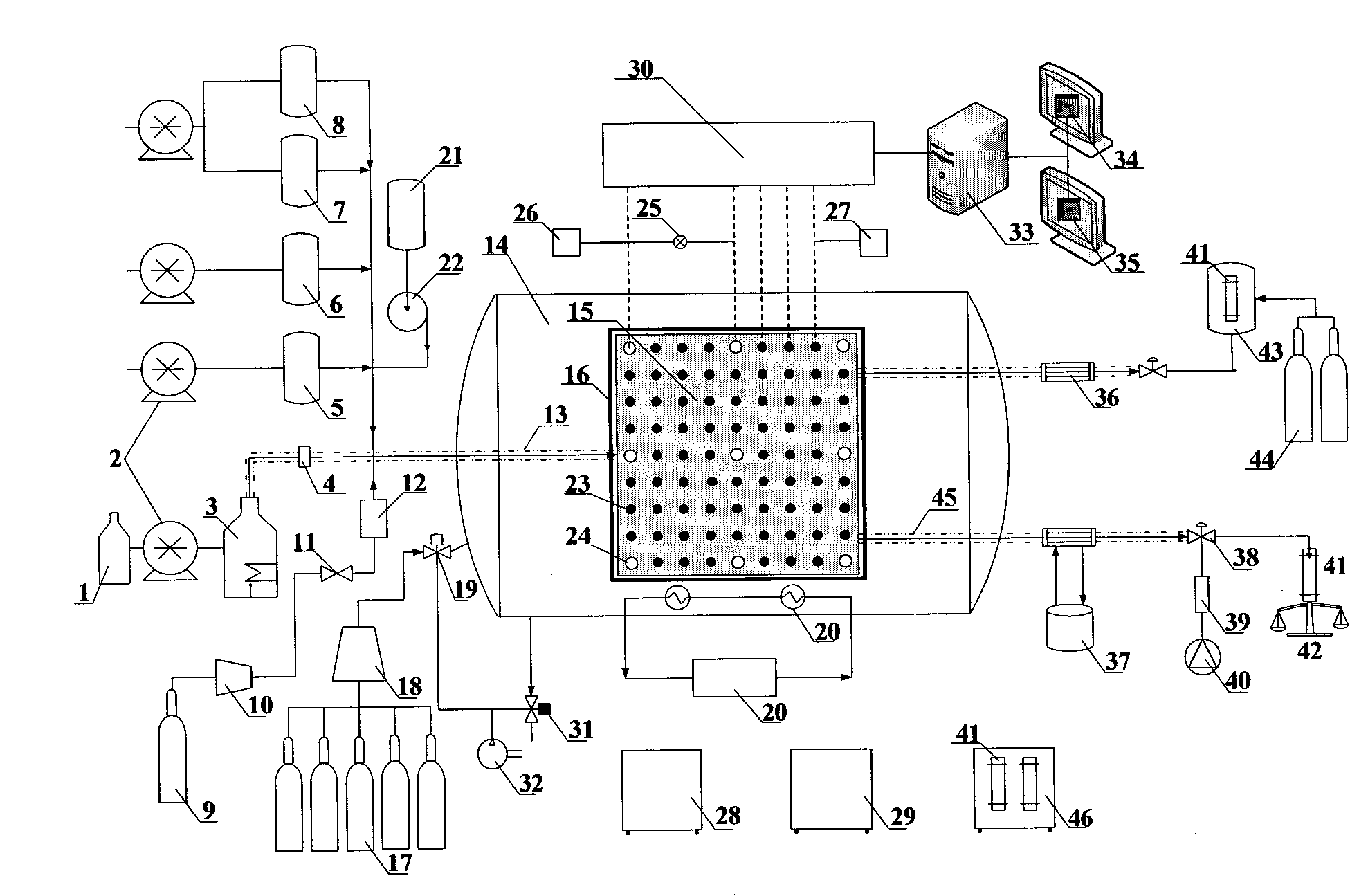

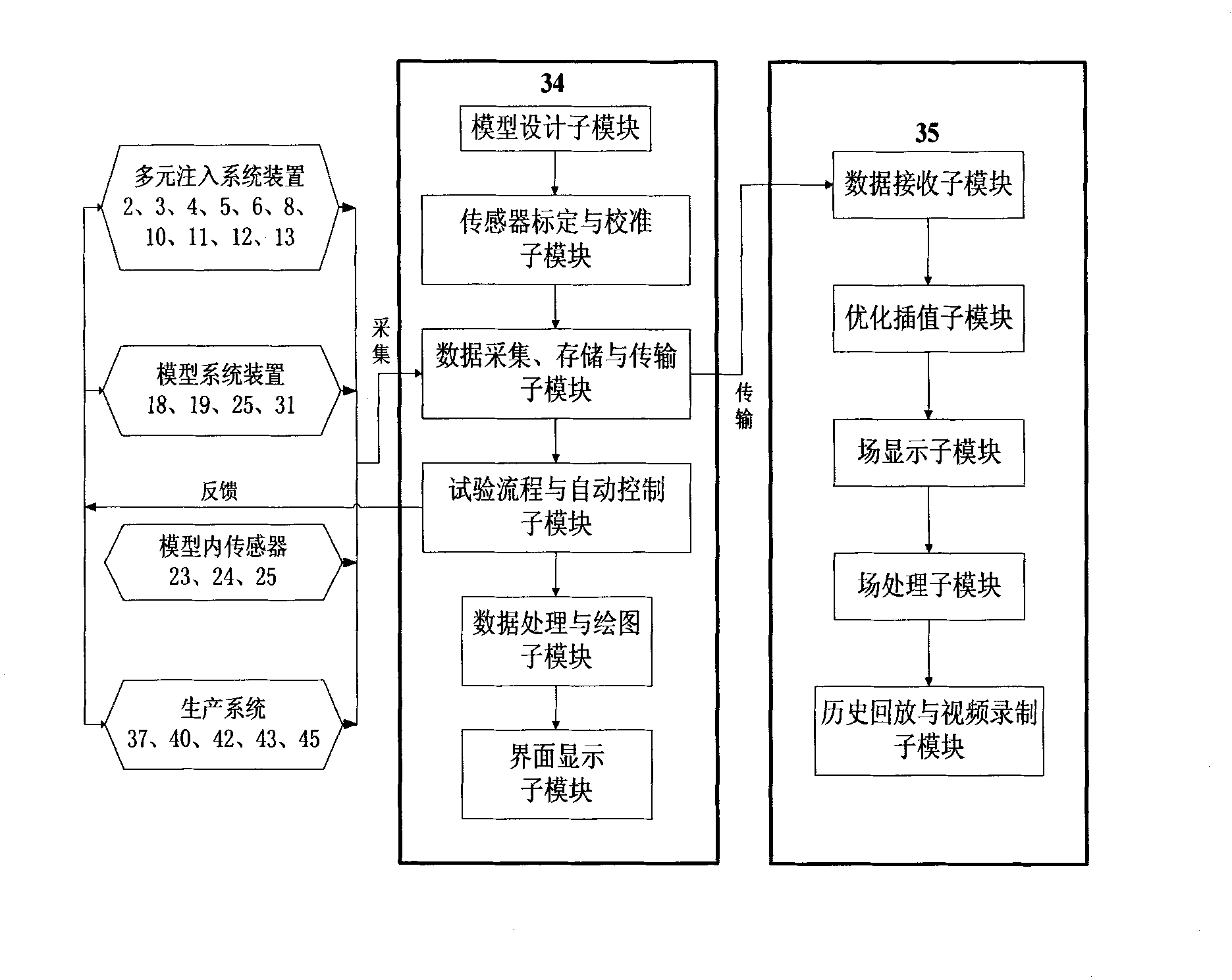

[0078] When carrying out the solvent-assisted steam oil recovery test, the water stored in the deionized water container 1 enters the steam generator group 3 through the constant speed and constant pressure pump group 2, and the steam generated reaches the steam required for the test after passing through the steam dryness monitor 4 At the same time, water is injected into the non-suspended chemical agent container group 7 through the constant speed and constant pressure pump group 2, and the test solvent stored in the non-suspended chemical agent container group 7 is displaced by water; After being mixed in the pipeline, it is injected into the model body 15; the model body 15 filled with sand and oil is fixed in the hyperbaric chamber 14, and the outer layer of the model body is wrapped with an insulating layer 16; the gas is pressurized by the gas compressor 18 and then injected into the hyperbaric chamber 14, through the opening and closing control of the injection pneumati...

Embodiment 2

[0080] When the gas-assisted steam oil recovery test is carried out, the water stored in the deionized water container 1 enters the steam generator group 3 through the constant speed and constant pressure pump group 2, and the steam generated reaches the steam required for the test after passing through the steam dryness monitor 4 Dryness; the gas reaches the injection pressure after the gas booster 10 and the gas pressure regulating valve 11, and the gas injection flow rate is set by the gas flow measurement and control device 12; the steam and the gas are mixed in the pipeline and then injected into the model body 15; filled with The model body 15 of sand and oil is fixedly placed in the hyperbaric chamber 14, and the outer layer of the model body is wrapped with an insulating layer 16; the gas is injected into the hyperbaric chamber 14 after being pressurized by the gas compressor 18, and injected through the pneumatic valve group 19 and The opening and closing control of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com