Preparation method of single-component anti-media adhesive

An anti-medium and adhesive technology, applied in the direction of adhesive types, polyurea/polyurethane adhesives, adhesives, etc., can solve the problem of affecting the bond fastness of composite adhesives, detachment of packaging bag film layers, and peeling Reduced strength and other problems, to achieve excellent media resistance, avoid penetration, high initial adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment 1 provides a preparation method of a one-component anti-medium adhesive, which can prepare a one-component anti-medium adhesive, which can be used in packaging materials to make the packaging materials resistant to acids, alkalis, In terms of pesticide resistance, it has more excellent medium resistance than traditional polyurethane. The preparation method includes:

[0025] (1) Synthetic polyester polyol:

[0026] Get each raw material of preparing polyester polyol by following mass percentage:

[0027] 5-10% of dimer acid, 5-10% of sebacic acid, 20-30% of diethylene glycol, 15-30% of phthalic acid, 5-10% of azelaic acid and 20-20% of neopentyl glycol 30%;

[0028] a. Primary esterification:

[0029] Add dimer acid, sebacic acid, and diethylene glycol into the polyester synthesis kettle, raise the temperature to 210-230°C, and react for 2-3 hours to complete the primary esterification;

[0030] In an esterification step, generally keep the amount of...

Embodiment 2

[0046] This embodiment 2 provides a preparation method of a one-component anti-medium adhesive, which preparation method comprises the following steps:

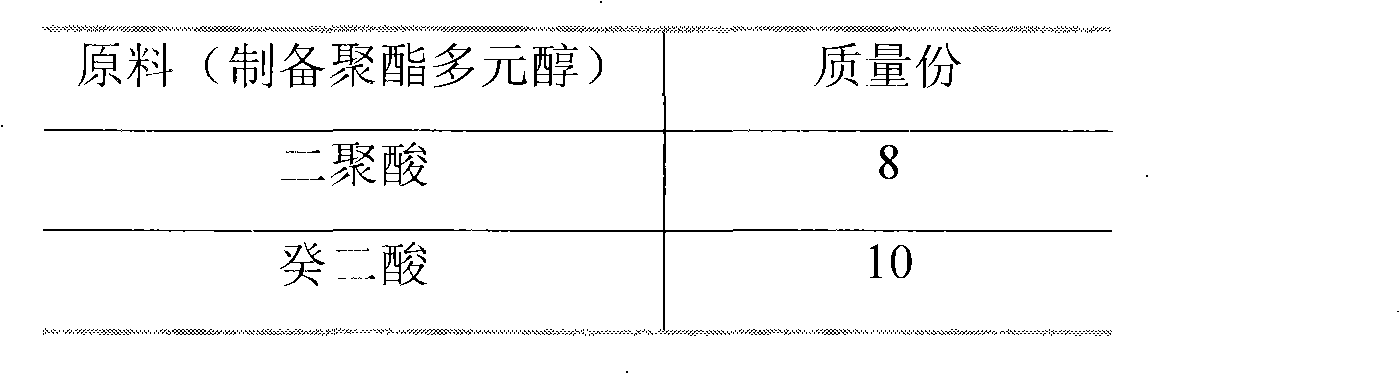

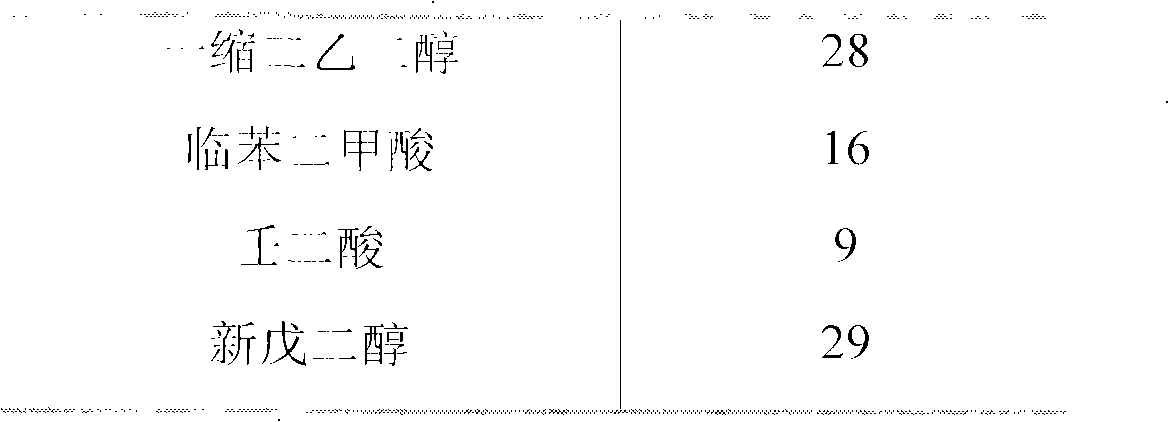

[0047] (1) prepare polyester polyol, get each raw material according to the following table proportioning ratio:

[0048]

[0049]

[0050] The concrete preparation method of polyester polyol:

[0051] a. Primary esterification:

[0052] Add the dimer acid, sebacic acid and diethylene glycol in the above formula into the polyester synthesis kettle, raise the temperature to 225°C, react for 3 hours, and distill 2 parts by mass of water;

[0053] b. Secondary esterification:

[0054] Add the phthalic acid, azelaic acid and neopentyl glycol in the above formula into the above-mentioned polyester synthesis kettle that has completed the primary esterification, raise the temperature to 230°C, and react for 5 to 6 hours; during the secondary esterification process, Pay attention to observe the water output of the polyester sy...

Embodiment 3

[0064] This embodiment 3 provides a preparation method of a one-component anti-medium adhesive, which preparation method comprises the following steps:

[0065] (1) prepare polyester polyol, get each raw material according to the following table proportioning ratio:

[0066]

[0067] The method for preparing polyester polyol is with embodiment 1, can refer to above-mentioned embodiment 2, does not repeat here;

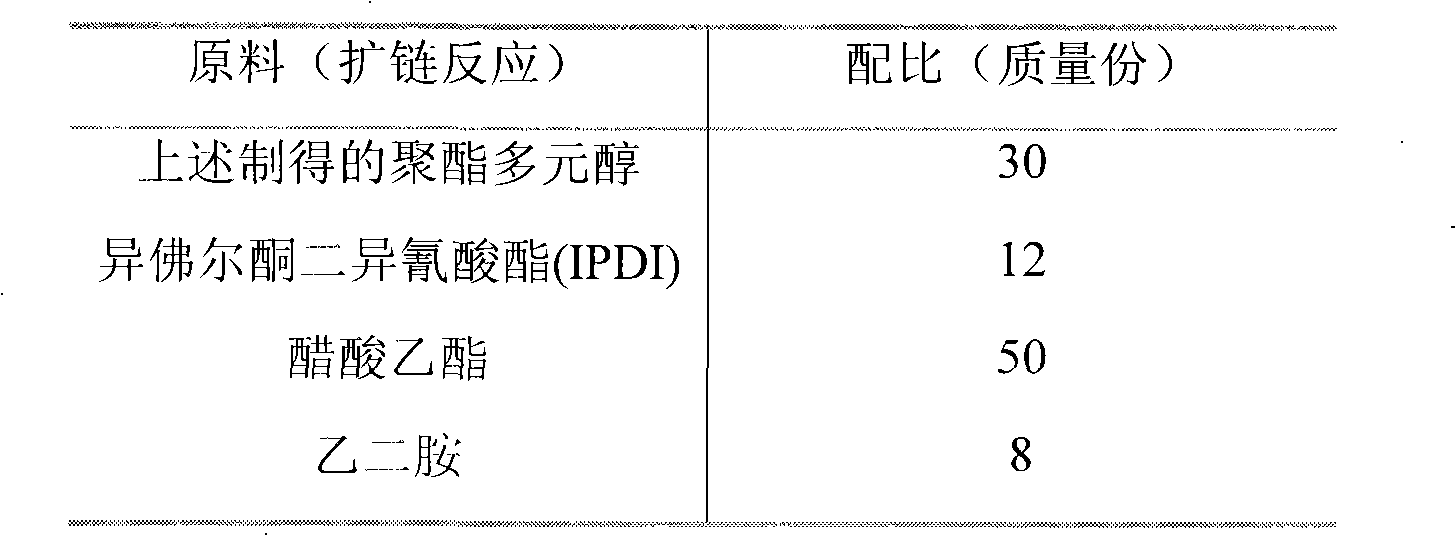

[0068] (2) chain extension reaction, get each raw material according to the proportioning of the table:

[0069]

[0070] The specific steps of the chain extension reaction:

[0071] Add the polyester polyol, hexamethylene diisocyanate (HDI) and ethyl acetate prepared above into the synthesis kettle, raise the temperature to 75°C-85°C, react for 3-4 hours and then cool down to 40°C-50°C Add isophorone diamine, react for 1 to 2 hours, the obtained product is a one-component anti-medium adhesive, test the prepared one-component anti-medium adhesive (can be sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com