Ultra-high crosslinked weak-polarity framework absorption resin and synthesis method thereof

A technology of ultra-high cross-linking and adsorption resin, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of reduced adsorption capacity, inability to obtain ultra-high cross-linked structure of weak polar skeleton, etc., and achieve high adsorption selectivity , high adsorption capacity, simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] At room temperature, dissolve 5g PVA and 25g NaCl in 470g deionized water in a 1000ml three-necked flask, and heat to 40°C; Mix the nitrile evenly, add it into the three-necked bottle, start stirring, adjust the size of the oil droplet between 0.3-1.0mm, start to heat up to 70°C, react for 4 hours, then continue to heat up to 85°C, react for 6 hours, stop the reaction, and let it stand After reaching room temperature, the resin is filtered out, and after washing and drying, a polyacrylate resin is obtained, which is a post-crosslinked matrix resin of the resin.

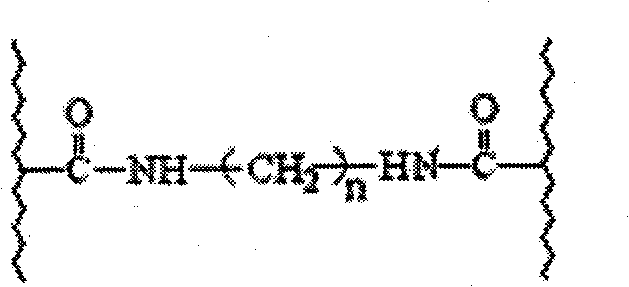

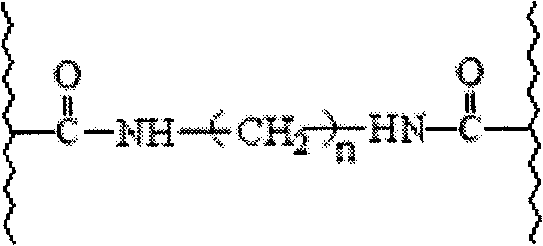

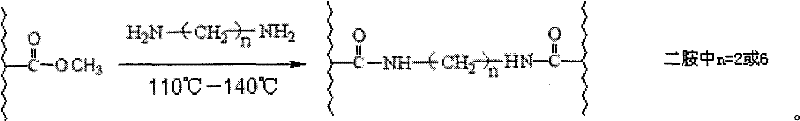

[0023] Add 50g of the above-mentioned polyacrylate matrix resin into a 1000ml three-necked bottle, fully swell with 200ml N,N-dimethylformamide, add 150g of ethylenediamine, stir evenly, raise the temperature to 110°C for 20 hours, stop the reaction, and Put it at room temperature, filter out the resin, wash the resin with a large amount of deionized water until the pH of the washing solution is 7-8, and dry it...

Embodiment 2

[0026] At room temperature, dissolve 5g PVA and 25g NaCl in 470g deionized water in a 1000ml three-necked flask, and heat to 40°C; Mix the nitrile evenly, add it into the three-necked bottle, start stirring, adjust the size of the oil droplet between 0.3-1.0mm, start to heat up to 70°C, react for 4 hours, then continue to heat up to 85°C, react for 6 hours, stop the reaction, and let it stand After reaching room temperature, the resin is filtered out, and after washing and drying, a polyacrylate resin is obtained, which is a post-crosslinked matrix resin of the resin.

[0027] Add 50g of the above-mentioned polyacrylate matrix resin into a 1000ml three-necked bottle, fully swell with 200ml N,N-dimethylformamide, add 300g of hexamethylenediamine, stir evenly, heat up to 140°C for 15 hours, stop the reaction, and Put it at room temperature, filter out the resin, wash the resin with a large amount of deionized water until the pH of the washing solution is 7-8, and dry it in a vac...

Embodiment 3

[0030] At room temperature, dissolve 5g PVA and 25g NaCl in 470g deionized water in a 1000ml three-necked flask, and heat to 40°C; mix 135g methyl acrylate, 15g divinylbenzene, and 1.5g azobisisobutyronitrile evenly, and add In the three-necked bottle, start stirring, adjust the size of the oil droplet between 0.3-1.0mm, start to heat up to 70°C, react for 4 hours, then continue to heat up to 85°C, react for 6 hours, stop the reaction, let it stand at room temperature, put the resin Filtrate, wash and dry to obtain polyacrylate resin, which is the matrix resin of resin post-crosslinking.

[0031] Add 40g of the above-mentioned polyacrylate matrix resin into a 500ml three-necked bottle, fully swell with 200ml N,N-dimethylformamide, add 120g of ethylenediamine, stir evenly, raise the temperature to 110°C for 20 hours, stop the reaction, and Put it at room temperature, filter out the resin, wash the resin with a large amount of deionized water until the pH of the washing solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com