Hydrotalcite-like structuring catalyst and method for catalytic synthesis of pseudo-ionone

A hydrotalcite structure and catalyst technology, applied in the field of membrane catalysis, can solve problems such as increasing mass transfer resistance and unfavorable multiphase contact material diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A. Sonicate the sheared aluminum sheet with a purity of 99.999% with acetone for 5 minutes, then use 8% sodium hydroxide solution for 10 minutes to remove the surface oxide layer, clean it with deionized water, and put it in an anodizing device for oxidation. Among them, the aluminum sheet is used as the anode, the lead plate is used as the cathode, the electrolyte is 1mol / L sulfuric acid solution, and the oxidation voltage is 2V / cm 2 Aluminum sheet, after anodizing for 75 minutes, take it out and rinse it with deionized water for later use;

[0023] B. Weigh 4.1024g Mg(NO 3 ) 2 ·6H 2 O and 7.6877g urea were dissolved together in 800ml deionized water, and after stirring evenly with a glass rod, put it into a polytetrafluoroethylene container;

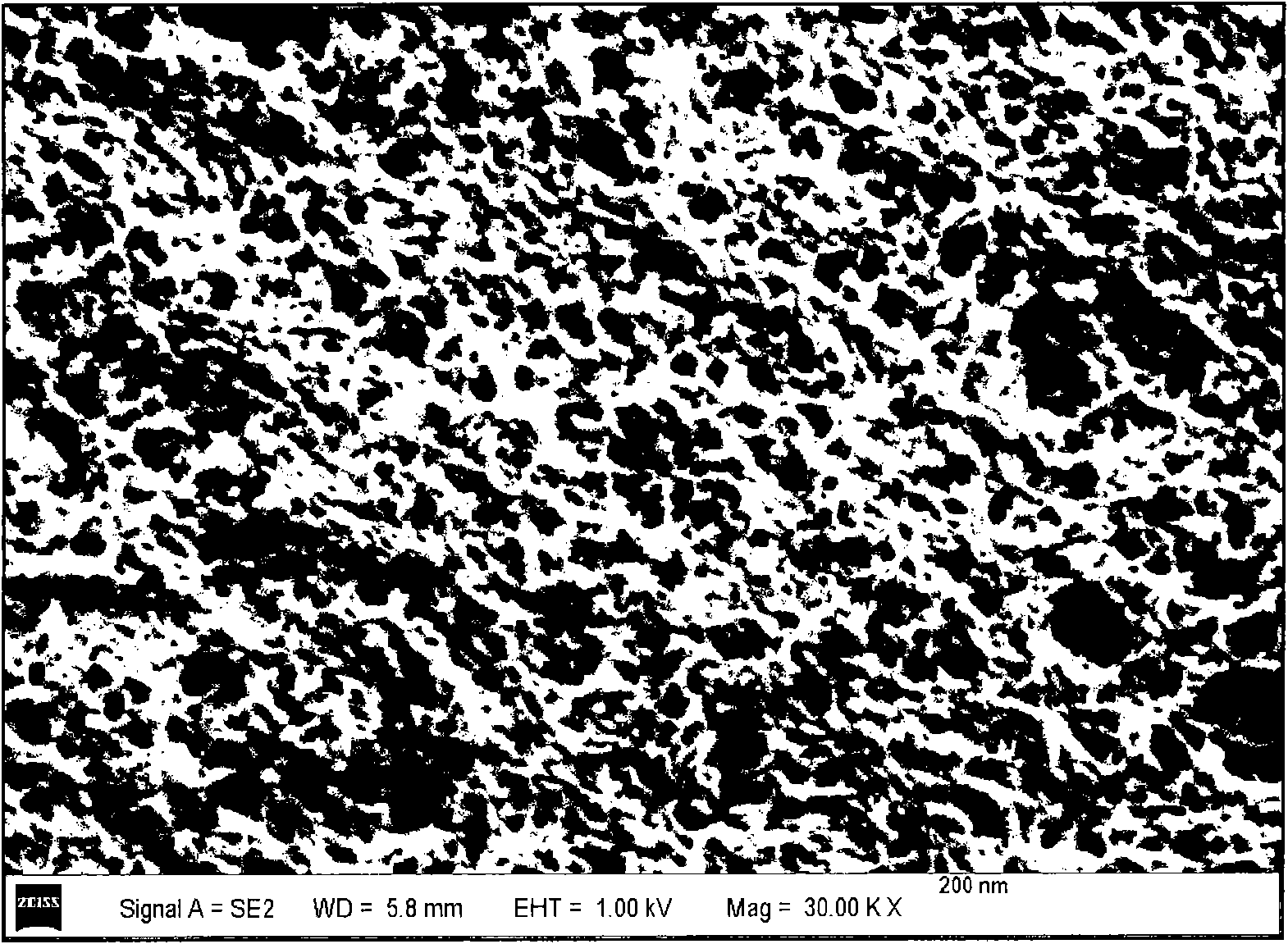

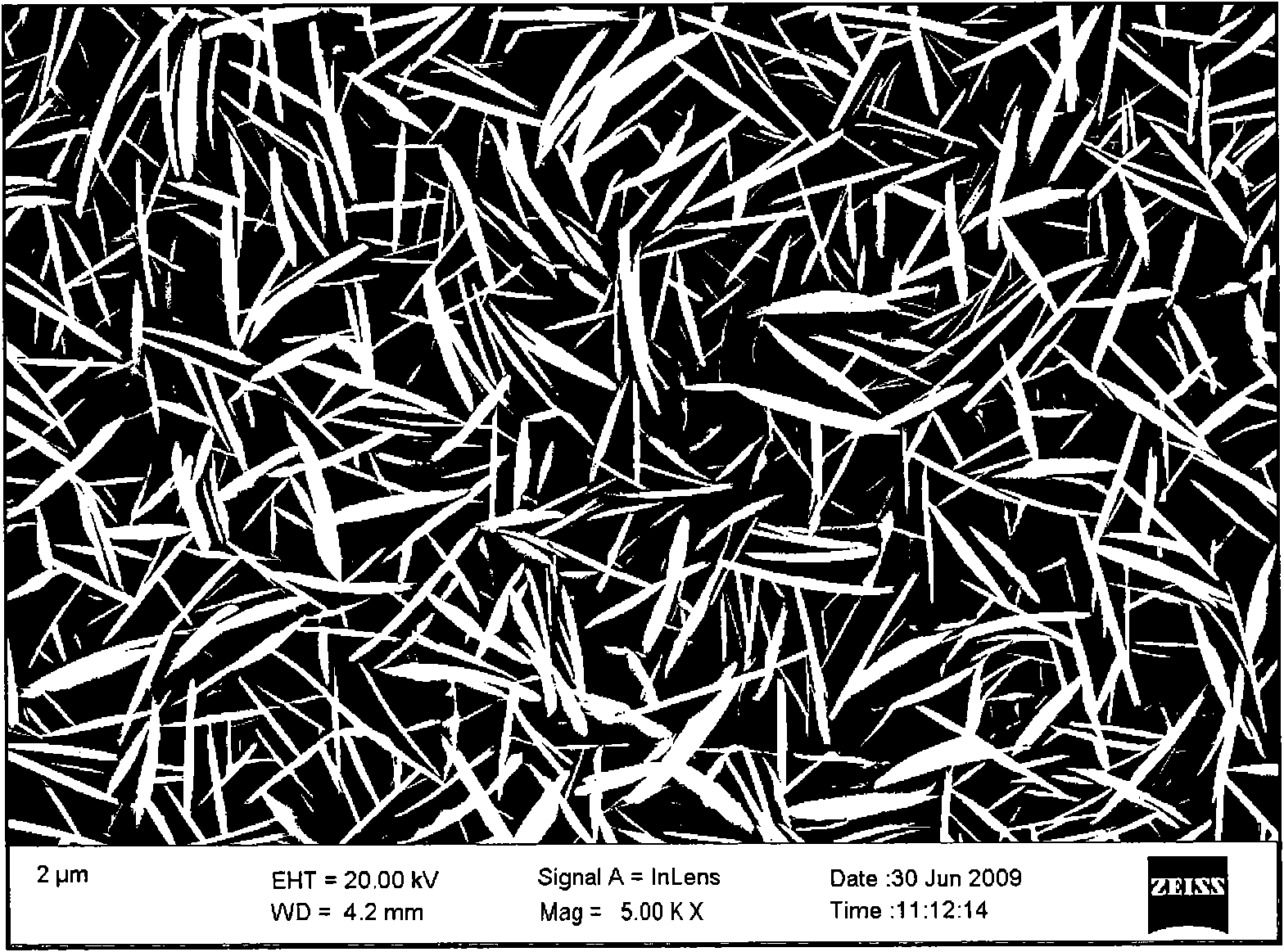

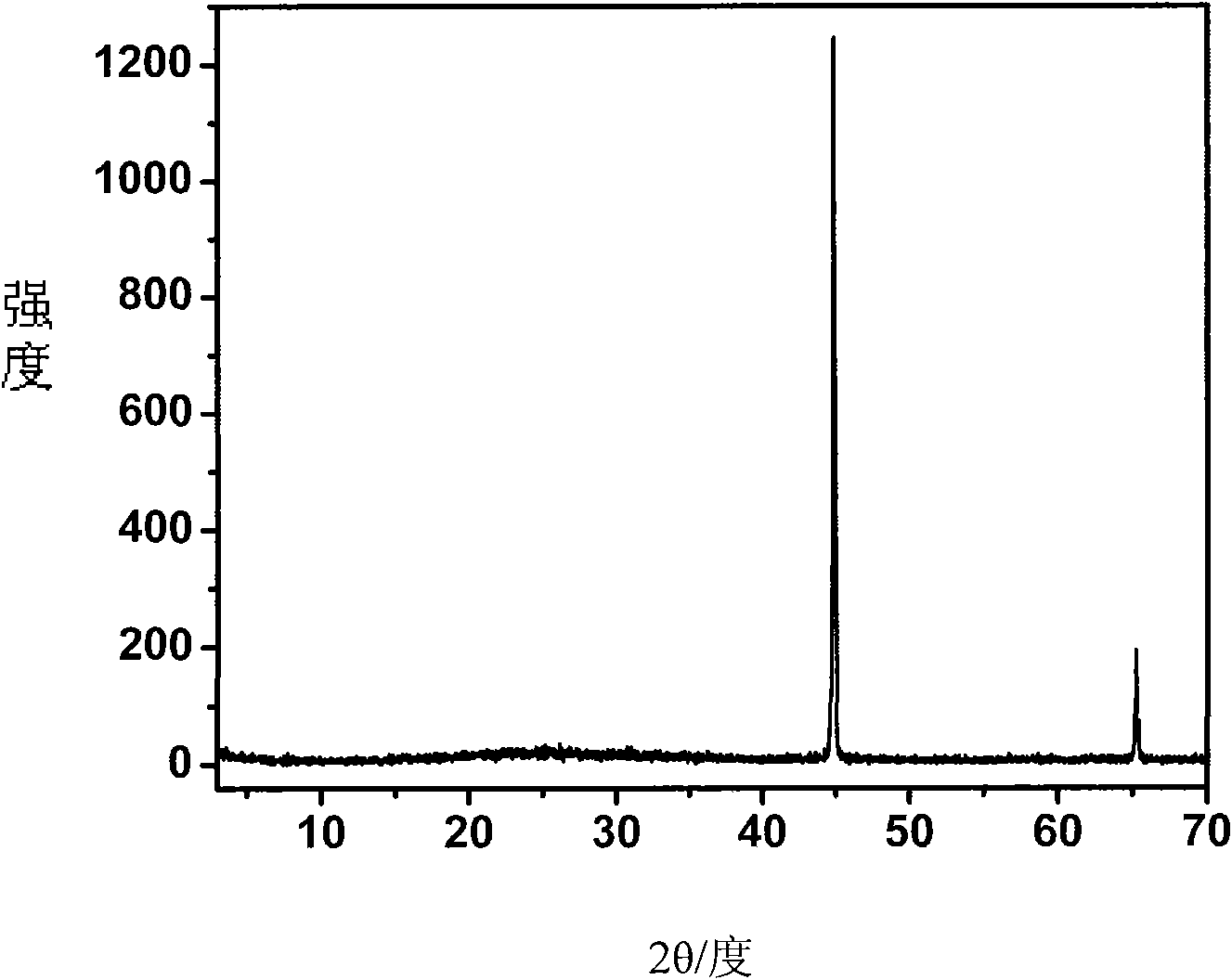

[0024] C. Take the aluminum sheet prepared earlier and take an area of 0.4m 2 Place the small piece in the mixed solution in the reaction vessel of step B, seal it well, react at a constant temperature at 90° for 3 days, r...

Embodiment 2

[0029] A. Sonicate the sheared aluminum sheet with a purity of 99.999% with acetone for 8 minutes, then use 5% sodium hydroxide solution for 8 minutes to remove the surface oxide layer, clean it with deionized water, and put it in an anodizing device for oxidation. Among them, the aluminum sheet is used as the anode, the lead plate is used as the cathode, the electrolyte is 1mol / L sulfuric acid solution, and the oxidation voltage is 2V / cm 2 Aluminum sheet, after anodizing for 75 minutes, take it out and rinse it with deionized water for later use;

[0030] B. Weigh 2.0512g Mg(NO 3 ) 2 ·6H 2 O and 3.8439g of urea were dissolved in 400ml of deionized water together, and after stirring evenly with a glass rod, put it into a polytetrafluoroethylene container;

[0031] C. Take the aluminum sheet prepared earlier and take an area of 0.4m 2 Place the small piece in the mixed solution in the reaction vessel of step B, seal it well, react at a constant temperature at 90° for 3 da...

Embodiment 3

[0036] A. Sonicate the sheared aluminum sheet with a purity of 99.999% with acetone for 9 minutes, then use 10% sodium hydroxide solution for 6 minutes to remove the surface oxide layer, clean it with deionized water, and put it in an anodizing device for oxidation. Among them, the aluminum sheet is used as the anode, the lead plate is used as the cathode, the electrolyte is 1mol / L sulfuric acid solution, and the oxidation voltage is 2V / cm 2 Aluminum sheet, after anodizing for 75 minutes, take it out and rinse it with deionized water for later use;

[0037] B. Weigh 1.282g Mg(NO 3 ) 2 ·6H 2 O and 2.4025g of urea were dissolved in 500ml of deionized water together, and after stirring evenly with a glass rod, put it into a polytetrafluoroethylene container;

[0038] C. Take the aluminum sheet prepared earlier and take an area of 0.4m 2 Place the small piece in the mixed solution in the reaction vessel of step B, seal it well, react at a constant temperature at 90° for 3 da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com