Super wear-resistant ceramic-steel composite lining plate for mixer and preparation method thereof

A composite liner and super wear-resistant technology, which is applied in the field of wear-resistant parts, can solve the problems of limited application of ceramic materials, difficulty in processing, and easy cracking, etc., and achieve the goal of improving equipment use efficiency, prolonging service life, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

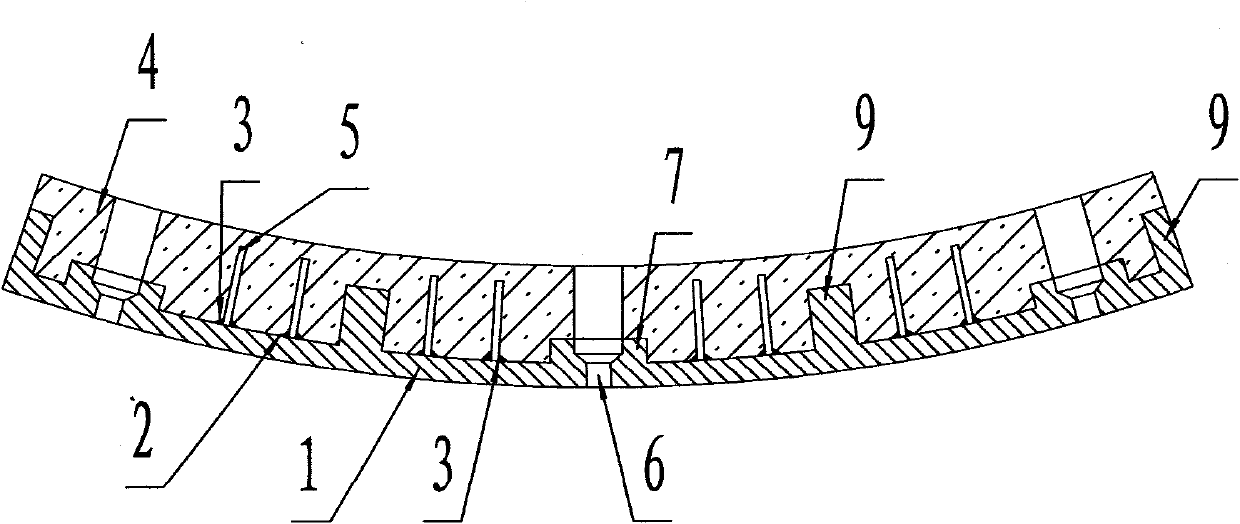

[0030] a. Overall design: According to the requirements of use, the geometric shape of the lining plate is designed to be arc-shaped and the size is 800×1000×45mm, and the molding mold is designed and manufactured; the thickness of the ceramic material layer is set to 40mm, and the thickness of the metal substrate is 5mm. And there are 9 installation parts with a thickness of 10mm; the diameter of the anchor nail is 5mm, the height is 30mm, about every 10cm 2 Set one; the width of the rib is 8mm, the height is 15mm, and one is set at about 15cm in the length and width directions.

[0031] Brown corundum (Al 2 o 3 ) segment sand raw material, the segment sand with a particle size of 15-20mm is the main aggregate, accounting for 45% by weight of the total amount, and the segment sand with a particle size of 6-8mm, 2-3mm, 1-2mm and 0-0.5mm The segment sand is auxiliary aggregate, and the weight percentages of the total amount are 20%, 15%, 10% and 5% respectively. The particle...

Embodiment 2

[0037] a. Overall design: According to the requirements of use, the geometric shape of the liner is designed as a fan-shaped flat plate, and its outline size is 600×800×35mm, and the molding mold is designed and manufactured; the thickness of the ceramic material layer is set to 29mm, and the thickness of the metal substrate 6mm, and there are 6 installation parts with a thickness of 6mm; the diameter of the anchor nail is 4mm, the height is 25mm, about every 20cm 2 Set one; the width of the rib is 8mm, the height is 15mm, and one is set at about 15cm in the length and width directions.

[0038] The ceramic material is made of silicon carbide section sand, with 8-10mm section sand as the main aggregate, accounting for 40% of the total weight, and three grades of 3-5mm, 1-2mm and 0-0.5mm section sand As the auxiliary aggregate, the percentage by weight of the total amount is 25%, 18 and 12% respectively; the particle size of the selected ceramic powder is 200 mesh, and the perc...

Embodiment 3

[0044] a. Overall design: According to the requirements of use, the geometric shape of the whole liner is flat and the size is 1000×1200×35mm. Due to the large area, the overall strength of the composite product is low, and it is not convenient for the composite process; therefore , using the splicing and combination design method, the whole liner is designed into four small pieces, a 5mm gap is reserved for the splicing position, and the geometric shape and size of each small liner are determined to be 500×600mm. The original whole liner has 9 There are 1 mounting bolt hole and 1 complete mounting bolt hole and 3 circular arc mounting bolt holes on each small liner after division, such as image 3 As shown; and design and make the forming mold accordingly; the thickness of the ceramic material layer is set to 31mm, the thickness of the metal substrate is 4mm; the diameter of the anchor nail is 3mm, the height is 13mm, about every 8cm 2 Set one; the reinforcing rib adopts a ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com