Sound passing member utilizing waterproof sound passing membrane and process for manufacturing the same

A waterproof sound-permeable membrane and a manufacturing method technology, applied to transducers, sensor parts, electrical components, etc. used underwater, can solve problems such as poor sound quality, unfavorable power consumption, and difficulty in popularizing products, and achieve energy suppression Loss, excellent sound permeability, effect of improving sound permeability

Active Publication Date: 2010-08-25

NITTO DENKO CORP

View PDF2 Cites 40 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When trying to achieve such a high degree of water resistance in products using sound-transmitting parts, it is inevitable that the sound will be difficult to hear, the sound quality will deteriorate (deterioration of the acoustic characteristics), and the default volume will need to be set to a high volume. The problem that it is disadvantageous in terms of power consumption

Such a problem becomes one of the reasons why it is difficult to popularize products with a high waterproof function

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

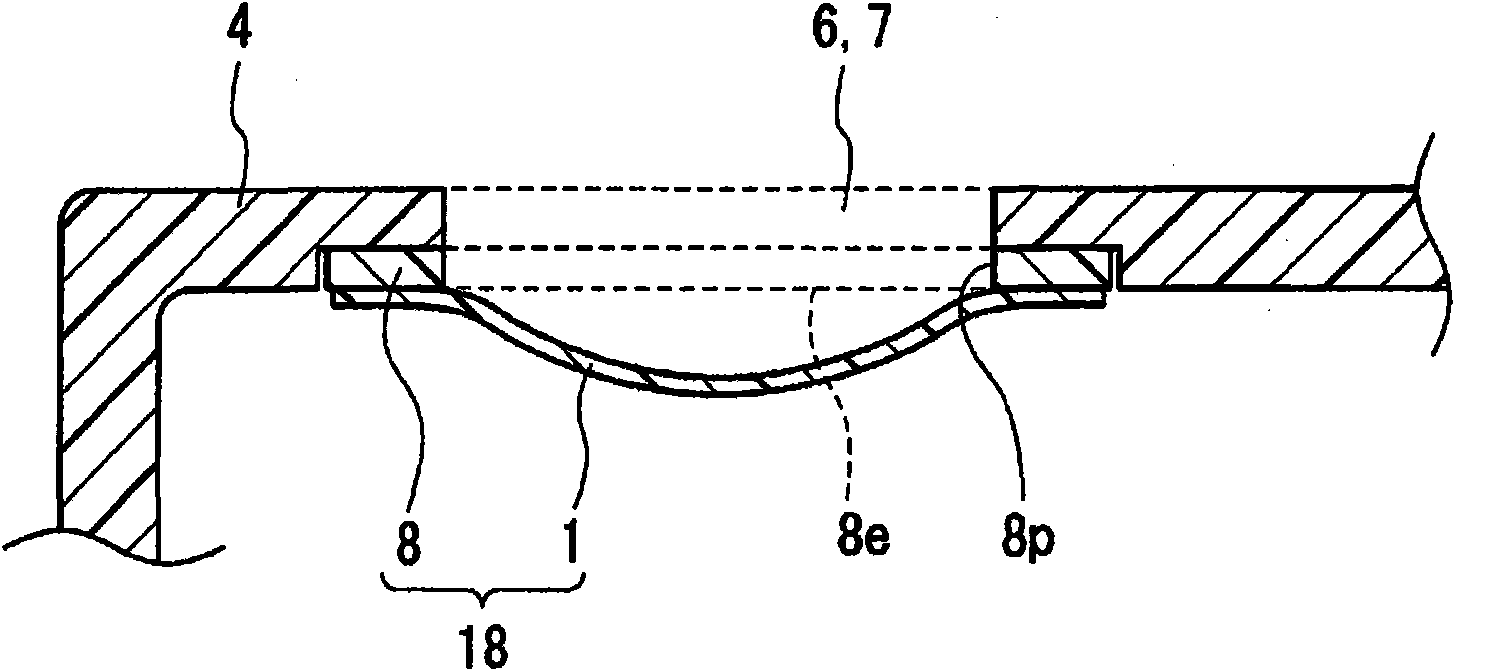

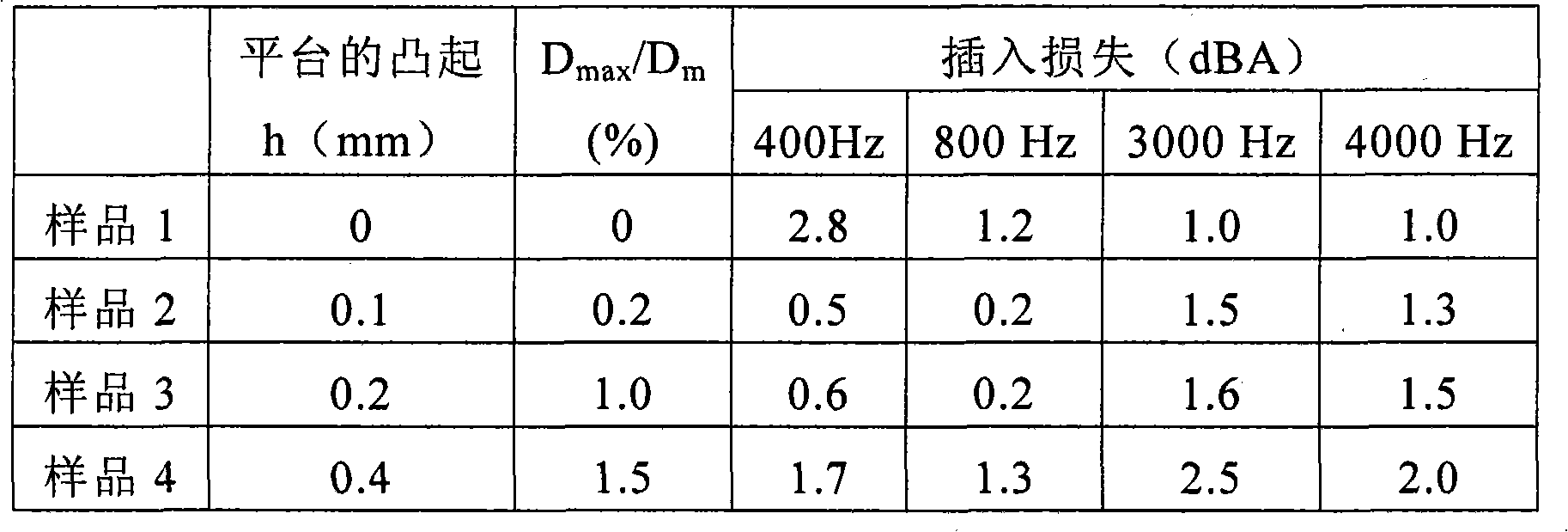

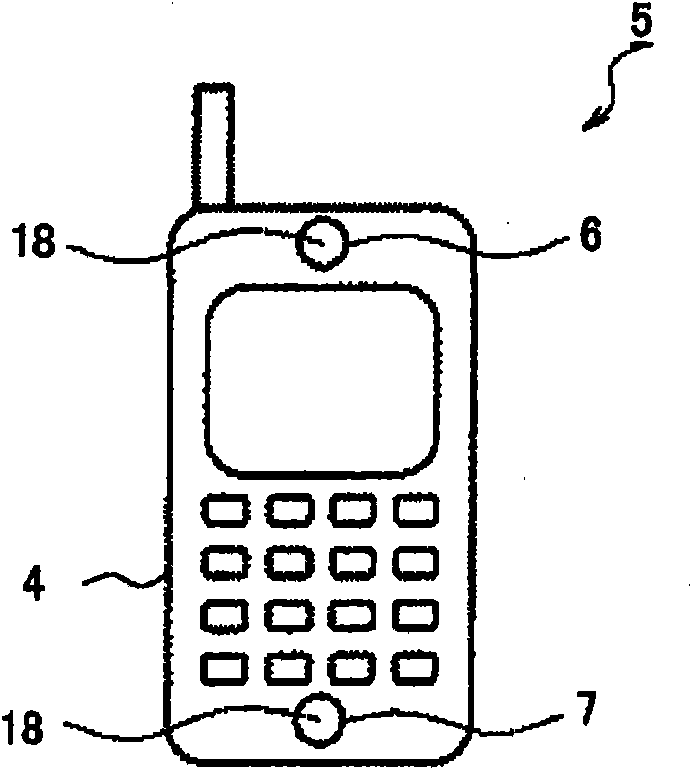

A sound passing member (18) comprising a waterproof sound passing membrane (1) adapted to allow the passage of sound but block the passage of liquid and a main body part (8) having an opening (8p) for the passage of sound, the opening (8p) covered by the waterproof sound passing membrane (1). The waterproof sound passing membrane (1) in a slack state is fixed to the main body part (8). A polytetrafluoroethylene porous membrane or ultrahigh-molecular-weight polyethylene porous membrane can appropriately be used as the waterproof sound passing membrane (1).

Description

technical field The present invention relates to a sound-permeable member using a waterproof sound-permeable membrane and a manufacturing method thereof. Background technique Electronic products such as mobile phones, notebooks, electronic notepads, and digital cameras are often used outdoors, so it is desirable to have a waterproof function. Parts where it is difficult to provide a waterproof function include sound-generating parts such as speakers and buzzers, and sound-receiving parts such as microphones. For example, openings are provided on the casing of the mobile phone at positions corresponding to the microphone and the loudspeaker. By closing the opening provided in the cabinet with the sound-transmitting member, both sound-permeability and waterproofness can be realized. The sound-permeable part is a part using a waterproof sound-permeable membrane that passes gas but blocks liquid. As an example of a waterproof sound-permeable membrane, as described in Japanes...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H04R1/00H04M1/18

CPCH04M1/03H04M1/18Y10T428/24331H04R1/00H04R1/44

Inventor 佐波映松田荣司江里口冬树

Owner NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com