Copper alloy powder and method for producing the same

A manufacturing method and technology of copper alloys, applied in metal/alloy conductors, cable/conductor manufacturing, conductive materials, etc., can solve the problems of not being able to exceed 800 °C and lowering, and achieve low resistivity, excellent oxidation resistance, and equipment costs. cheap effect

Inactive Publication Date: 2010-08-25

SINTOKOGIO LTD

View PDF5 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, still unable to exceed 800°C

As mentioned above, the copper alloy powders used in the conductive pastes of electronic parts disclosed in the prior art all have improved oxidation resistance, sintering start temperature, and resistivity due to the added elements, but it is still desirable to add Reduction of material cost of elements and further increase of sintering start temperature

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

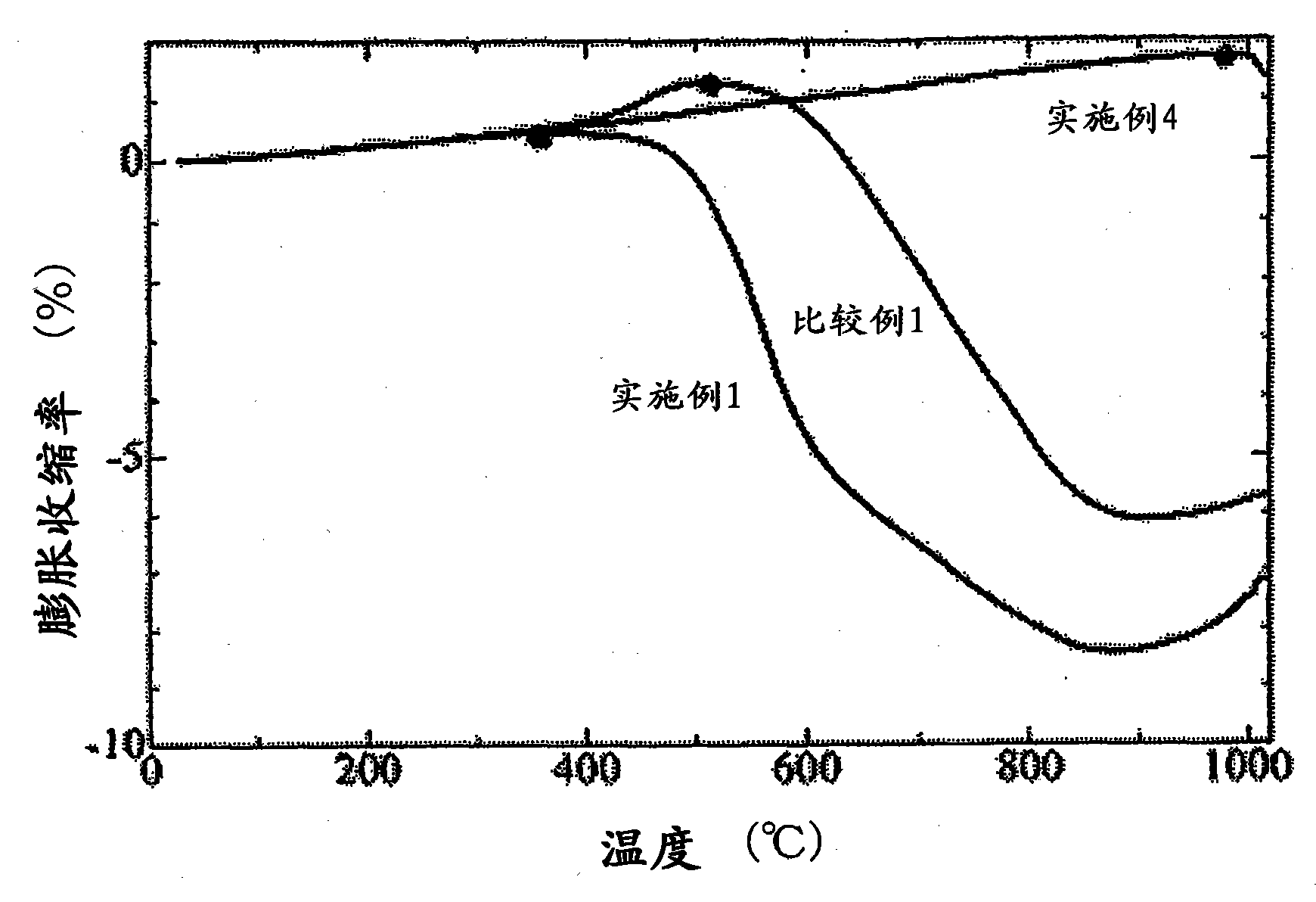

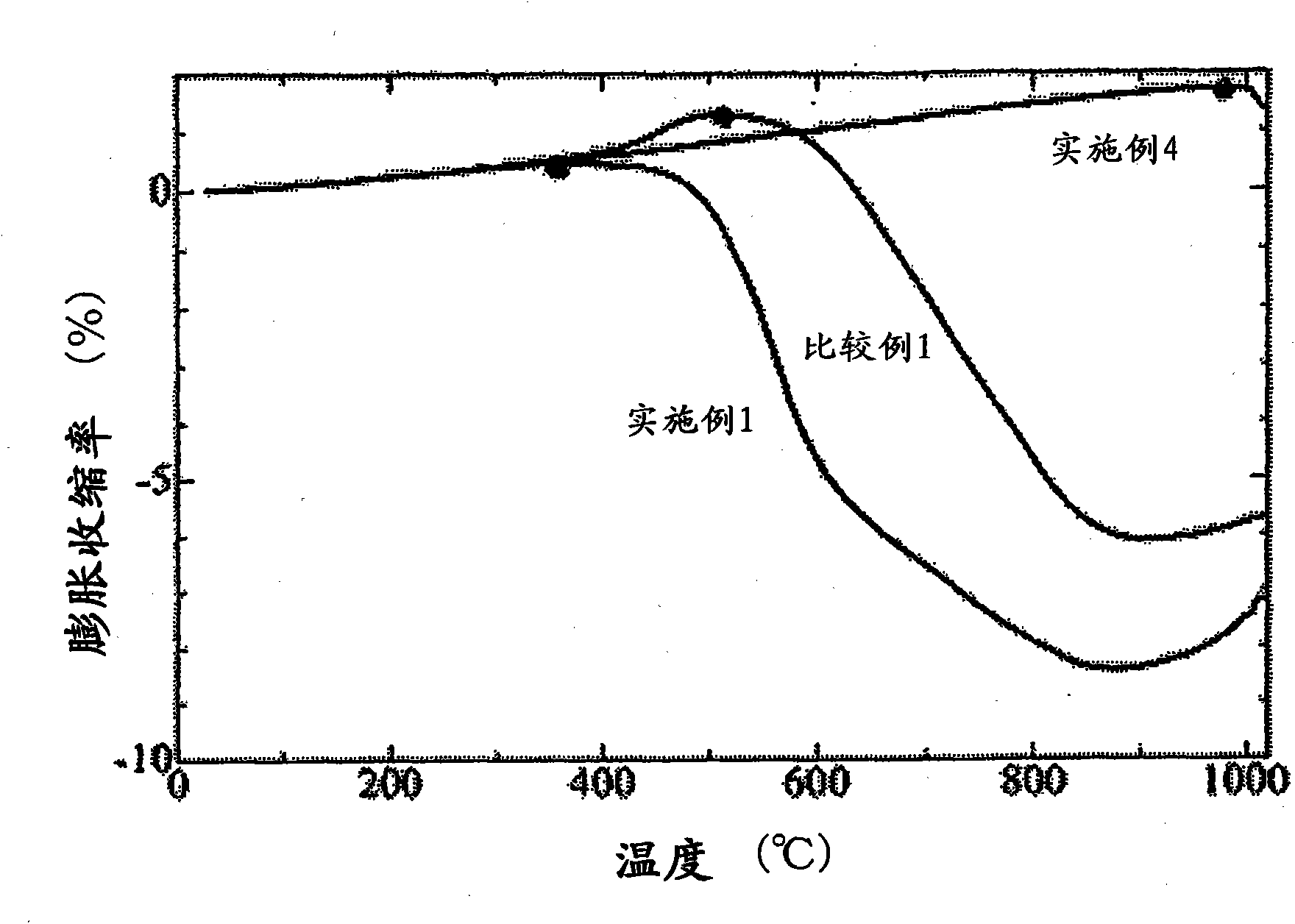

Login to View More Abstract

Disclosed is a copper alloy powder having excellent oxidizability and electrical conductivity, whose sintering starting temperature can be set discretionally. This copper alloy powder enables low production cost, that is composed of the costs for raw materials and production facilities. Specifically disclosed is a copper alloy powder composed of 0.05-3.00% by mass of aluminum, and the balance of copper and unavoidable impurities, while additionally containing 0.01-0.10% by mass of boron, if necessary. This copper alloy powder is granulated by a water atomization process.

Description

Copper alloy powder and manufacturing method thereof technical field The present invention relates to copper alloy powder most suitable for conductive paste used in electronic components and a method for producing the same. Background technique Copper alloy powder is widely used as a material for conductive paste or conductive filler used for circuit formation of electronic circuit boards, embedding of through holes, or electrode formation of multilayer capacitors. As its characteristics, low requirements are required. Resistivity and high oxidation resistance, and sintering characteristics with the base material corresponding to the application are required. For example, when used to form the outer layer circuit of a multilayer capacitor, in order to mount the external electrodes to the completed sintered body and connect to the substrate pattern, it is desired not to damage the sintered body, and to prevent resistance due to oxidation It is hoped that it will not be ox...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C9/01B22F1/00B22F9/08C22C9/00H01B1/02H01B13/00

CPCH01B1/026C22C9/01B22F2009/0828C22C9/00B22F9/082

Inventor 木野泰志梶田浩二玉木贤治

Owner SINTOKOGIO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com