Weather-proof micro-trigger controlled silicon and manufacturing method thereof

A manufacturing method and micro-triggering technology, which are applied in semiconductor/solid-state device manufacturing, electrical components, thyristors, etc., can solve the problems of increased cost, large on-state voltage drop, and thyristor is susceptible to interference, and achieves improved ignition energy, The effect of faster switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

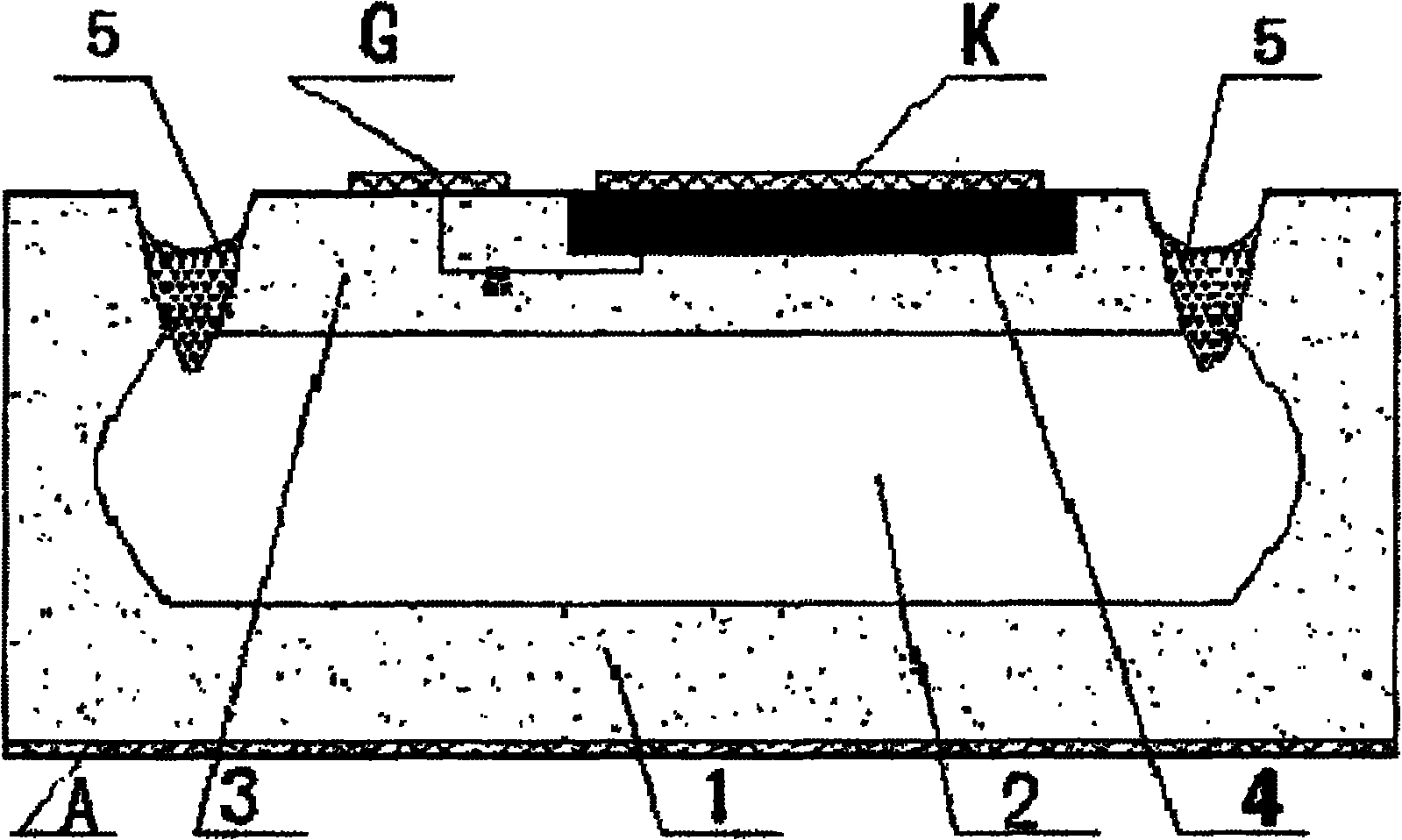

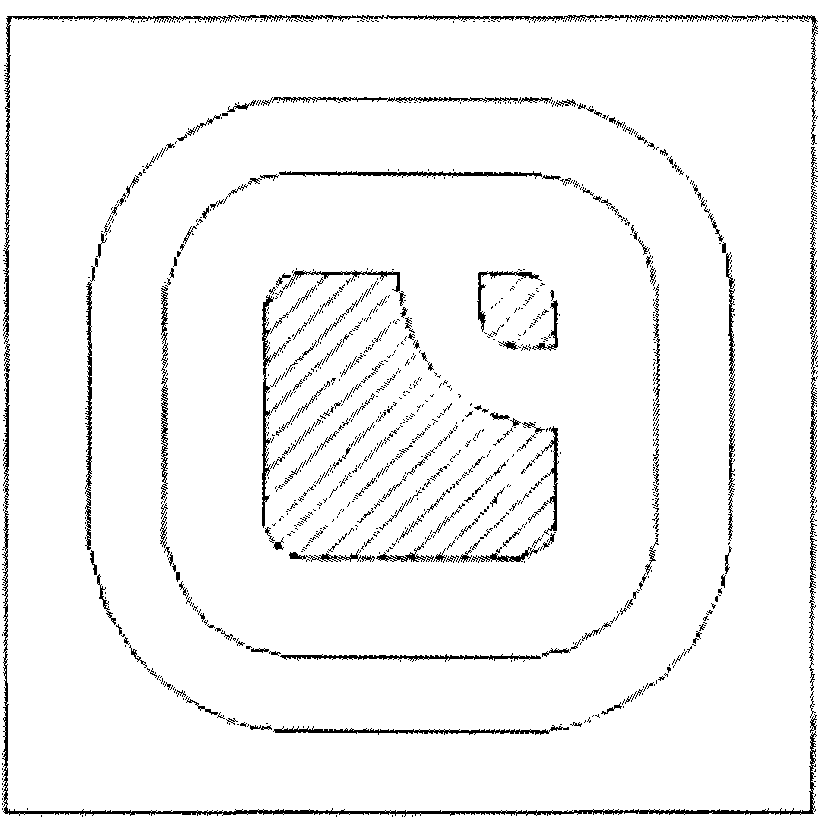

[0031] Please refer to Fig. 4, Fig. 5 and Fig. 6 together. The embodiment of the weather-resistant micro-trigger thyristor of the present invention is a PNP structure, and the PNP structure includes a P-type anode region 1, an N-type long base region 2, and a P-type Short base region 3.

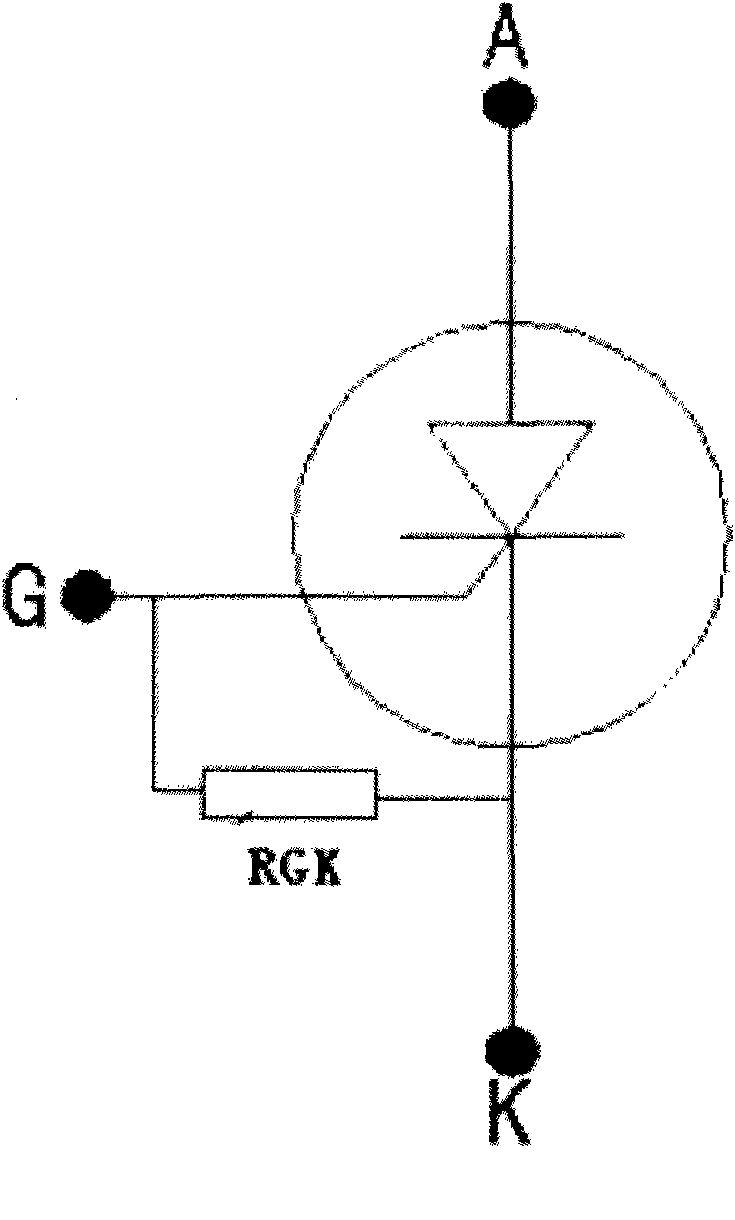

[0032] One side of the PNP structure is P-type silicon, that is, the short base region 3 is provided with N + emitter region 4 and gate electrode G, the N + A cathode electrode K is arranged on the emitter region 4 .

[0033] An anode electrode A is provided on the P-type silicon on the other side of the PNP structure, that is, the anode region 1 .

[0034] In the PNP structure near N + The emitter side is provided with a laterally integrated resistor R O , the laterally integrated resistor R O is a negative temperature coefficient type thermistor, and is connected between the gate electrode G and the cathode electrode K.

[0035] The laterally integrated resistor R O When the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com