Electric forklift

A technology for electric forklifts and frames, which is applied to electric power units, power units, vehicle components, etc., can solve the problems of battery box resonance, high power of the forklift, and many power sources, so as to improve work efficiency and endurance. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

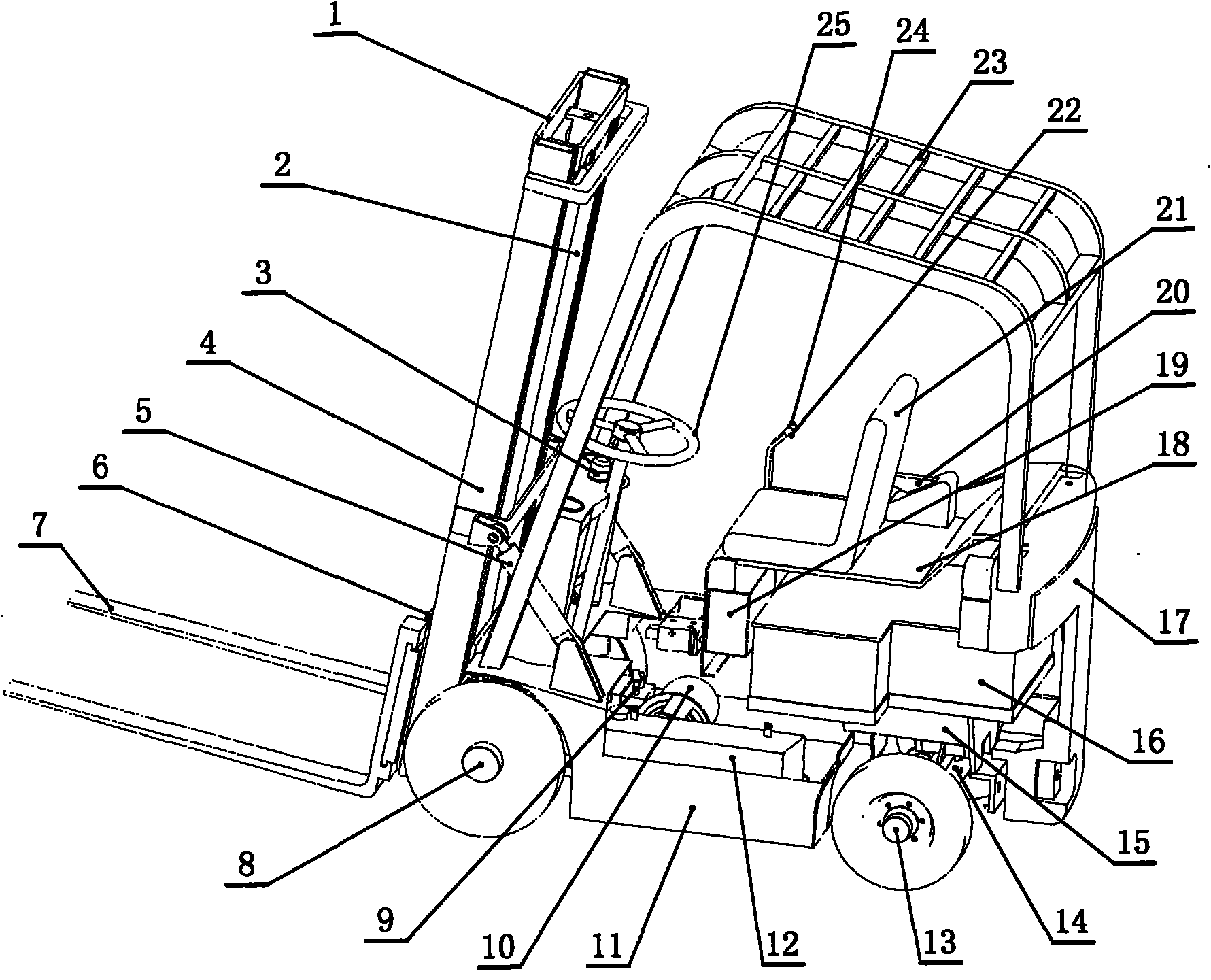

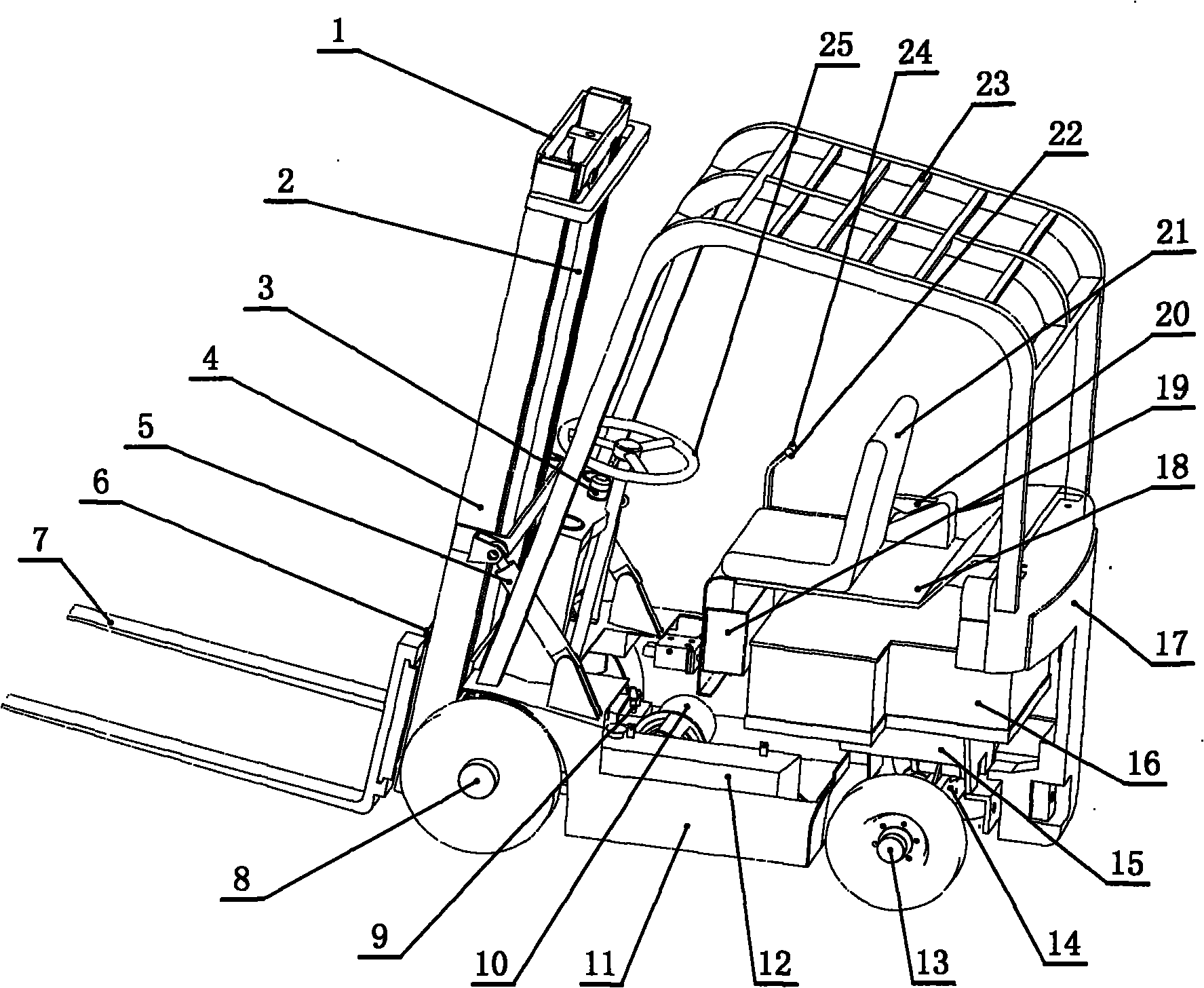

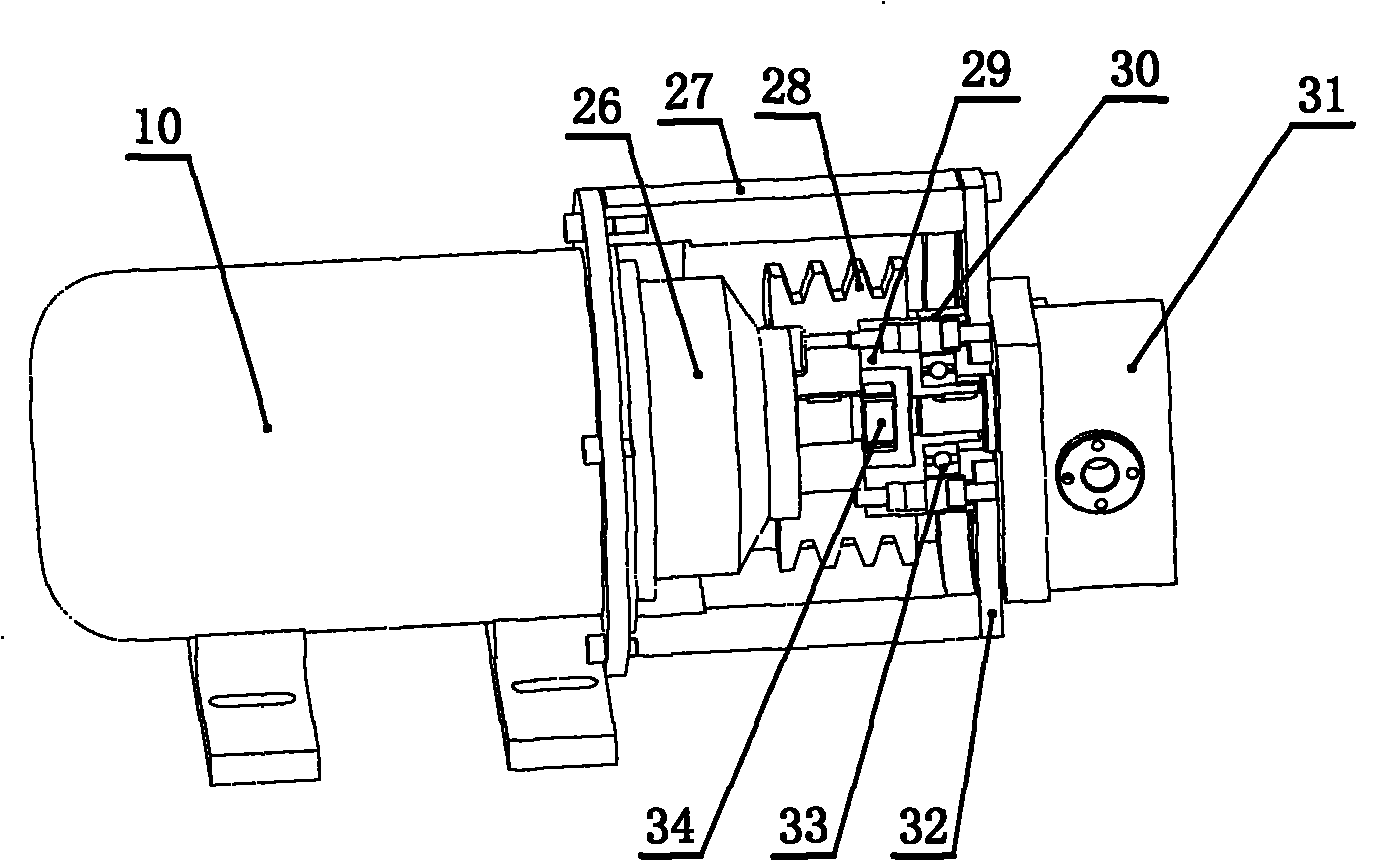

[0032] An electric forklift, as shown in Fig. 1, Fig. 2 and Fig. 3, comprises a vehicle frame 11, a front axle 8 is fixedly connected to the front of the vehicle frame 11, a front wheel is installed on the front axle 8, and the rear part of the vehicle frame 11 is fixedly connected Rear axle 13 is arranged, and rear wheel is installed on the rear axle 13; Vehicle frame 11 front end is hinged with fixed door frame 4, fixed door frame 4 slides up and down and is connected with movable door frame 1, and movable door frame 1 is connected with sliding frame up and down sliding 6. A cargo fork 7 is installed on the sliding frame 6; a motor 10 is fixedly installed on the frame 11, and the motor 10 is connected to the front wheel; a battery box 18 is fixedly connected to the frame 11, and a battery 16. The storage battery 16 is connected to the motor 10 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com