Preparation method of white thiophanate methyl

A technology of thiophanate-methyl and white, which is applied in the field of preparation of white thiophanate-methyl, which can solve the problems of easy oxidation and darkening of color, and achieve the effects of low production cost, simple operation and low investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

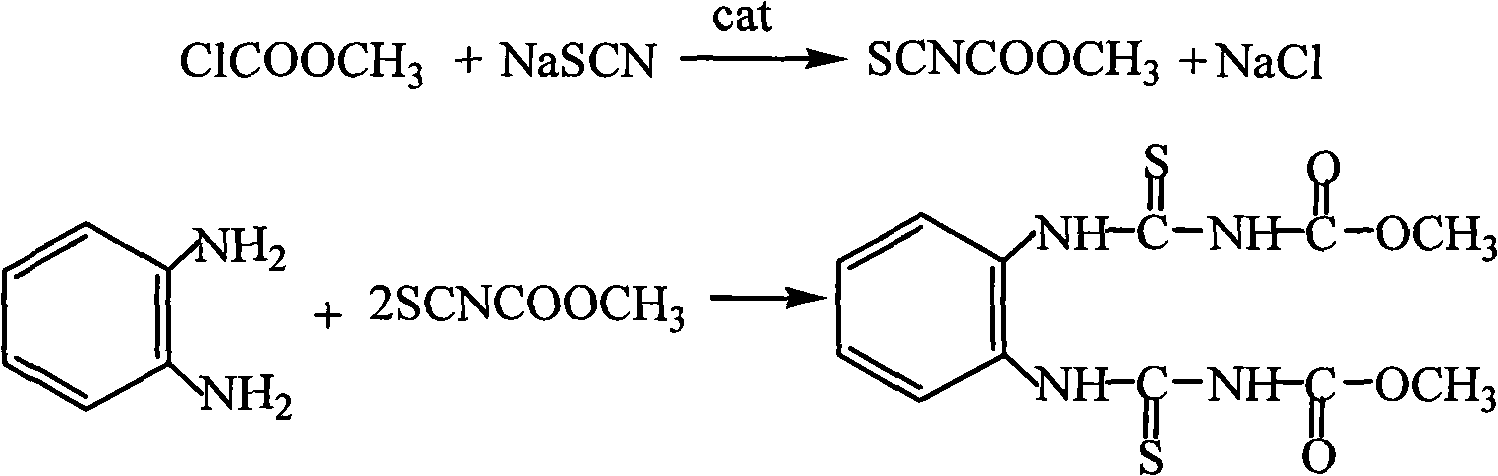

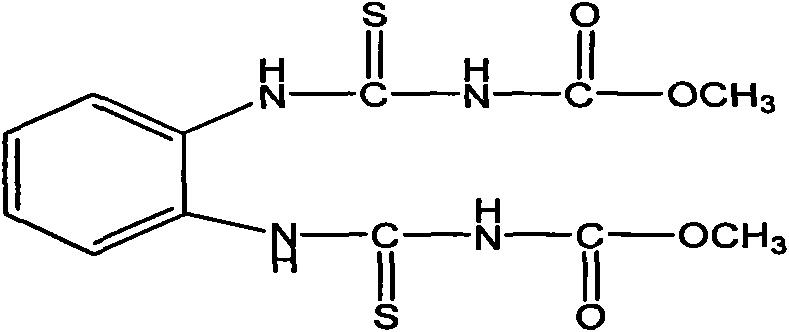

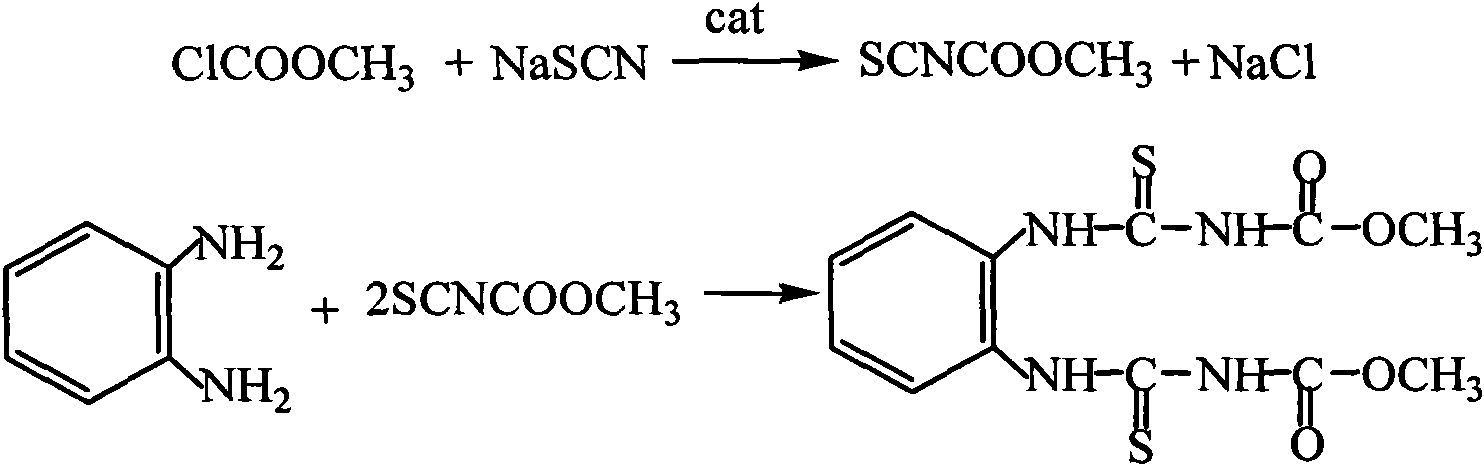

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Add 180ml dichloroethane, 16.4g dark brown o-phenylenediamine (Mr=108, 0.15mol, content 99%, industrial product) and 0.17g silicon alginate, heat up to reflux, and after reflux for 1 hour, filter while hot, and cool the filtrate for later use. Add 26.3g sodium thiocyanate (Mr=81, 0.318mol, 98%, industrial product), 50mL dichloroethane and 1.0g Catalyst N, N-dimethylaniline (98%, industrial product), start stirring, and drop 30.7g (Mr=94.5, 0.318mol, 98%, industrial product) methyl chloroformate into the reaction flask at room temperature , After dropping, incubate and react at 40-45°C for 30 minutes. After the heat preservation is completed, reduce the temperature of the system to below 20°C, and add the mixture of o-phenylenediamine and organic solvent obtained after the decolorization treatment in batches. The reaction is exothermic violently, and the temperature is controlled below 60°C. Timed reaction for 1 hour, cooling to below 20°C, filtering, adding 200ml of w...

Embodiment 2

[0019] Add 180ml dichloroethane, 16.4g light brown o-phenylenediamine (Mr=108, 0.15mol, 99%, industrial product) and 0.49g silicon alginate, heat up to reflux, and after reflux for 1 hour, filter while hot, and cool the filtrate for later use. Add 26.3g sodium thiocyanate (Mr=81, 0.318mol, 98%, industrial product), 50mL dichloroethane and 1.0g Catalyst N, N-dimethylaniline (98%, industrial product), start stirring, and drop 30.7g (Mr=94.5, 0.318mol, 98%, industrial product) methyl chloroformate into the reaction flask at room temperature , After dropping, incubate and react at 40-45°C for 30 minutes. After the heat preservation is completed, reduce the temperature of the system to below 20°C, and add the mixture of o-phenylenediamine and organic solvent obtained after the decolorization treatment in batches. The reaction is exothermic violently, and the temperature is controlled below 60°C. Time the reaction for 1 hour, cool down to below 20°C, filter, add 200ml of water to ...

Embodiment 3

[0021] The 99% o-phenylenediamine industrial product that handles is brown, and organic solvent is ethyl acetate, and all the other are identical with embodiment 1, obtain thiophanate-methyl product 50.2g, content 97.2%, yield 95.1% (based on o-phenylenediamine Diamine meter), whiteness: 85.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com