Method for preparing membrane electrode for hydrophilicity and hydrophobicity-adjustable proton exchange membrane fuel battery on the basis of catalyst/membrane technology

A proton exchange membrane technology with adjustable hydrophilicity and hydrophobicity, which can be used in battery electrodes, circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

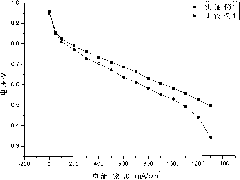

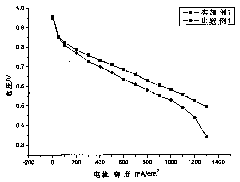

Image

Examples

Embodiment 1

[0036] A method for preparing a membrane electrode for a proton exchange membrane fuel cell with adjustable hydrophilicity and hydrophobicity, the preparation steps are as follows:

[0037] 1. Get 3g of Pt / C catalyst (carbon-supported Pt catalyst, the mass content of Pt is 40%), add 15g of water and mix with the catalyst evenly to make the catalyst wet; get another 1g of PTFE emulsion with a mass concentration of 60%, add 12g of water Mix well, then add 20g of 5% Solution (produced by DuPont Company, 5% is Nafion resin, 95% is water and low-boiling point alcohol components), these mixed solutions are poured into the wetted catalyst and mixed evenly to prepare slurry;

[0038] 2. Pretreatment of proton exchange membrane: take The membrane is a proton exchange membrane with a thickness of 51 μm; immersed in 5% H 2 o 2 heat treatment at 70°C for 1 hour, rinsed with deionized water three times, and then immersed in 0.5mol / L H 2 SO 4 Heat treatment in the solution at 70°C fo...

Embodiment 2

[0046] A method for preparing a membrane electrode for a proton exchange membrane fuel cell with adjustable hydrophilicity and hydrophobicity, the preparation steps are as follows:

[0047] 1. Take 1.2g of Pt black catalyst, add 3.6g of water to wet the catalyst; take another 2g of PTFE emulsion with a mass concentration of 60%, add 5g of water to disperse evenly, then add 40g of 3% sulfonated trifluorostyrene solution and mix Uniformly, finally pour these mixed solutions into the wetted catalyst and disperse evenly to obtain a slurry;

[0048] 2, The pretreatment method of membrane, PTFE membrane is identical with embodiment 1, adopts screen printing equipment to be coated with slip on PTFE membrane, with N 2 For protective gas, dry at 100-120°C, heat to remove the solvent, and form a catalytic layer on the PTFE membrane; the screen size is 40-200 mesh nylon mesh, and the single-pass printing area is 15×30cm. Put the PTFE membrane medium coated with the catalyst layer into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com