Device and method for determining optimal focal plane position of lithography machine

A technology of the best focal plane and lithography machine, which is applied in the photolithography process exposure device, the microlithography exposure equipment, the photolithography process of the pattern surface, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

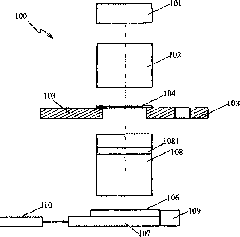

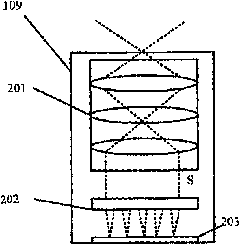

[0041] like figure 1As shown, the device for measuring the best focal plane position of a lithography machine according to the embodiment of the present invention includes a light source 101, an illumination system 102, mask tables 103, 105, a mask 104, a silicon wafer 106, a workpiece table 107, an optical imaging system 108, wave aberration sensor 109, and interferometer 110. The light source 101 is a deep ultraviolet laser light source that generates light beams. The illumination system 102 shapes the light beams to produce desired light beams. The workpiece table 107 carries and positions the silicon wafer 106. The optical imaging system 108 has a projection objective lens 1081. The optical system images the mask image on the silicon wafer. On the sheet 106 , a wave aberration sensor 109 is located on the workpiece table 107 to measure the wave aberration of the projection objective lens 1081 , and the interferometer 110 is used to position the work table 107 . The light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com