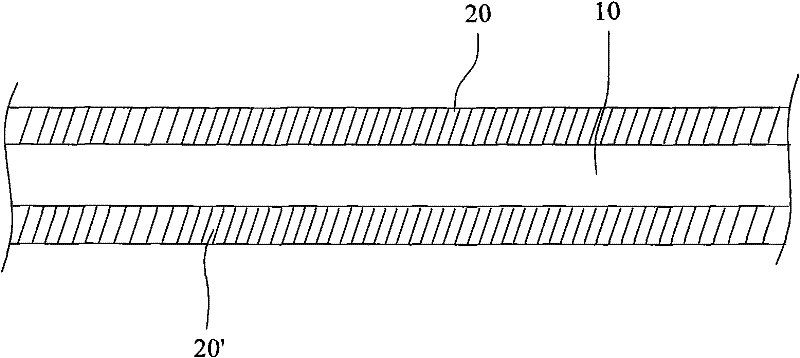

Coated paper of mercury-free zinc manganese dry cell for high-speed battery production line and preparation method thereof

A manganese dry battery and pulp paper technology, which is applied in the field of dry battery manufacturing, can solve the problems of defective batteries, increased waste products, difficulty in feeding the pulp paper into the zinc cylinder, and high price, and achieve improved barrier performance and corrosion inhibition performance, good mechanical and Chemical stability and effect of improving mechanical adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

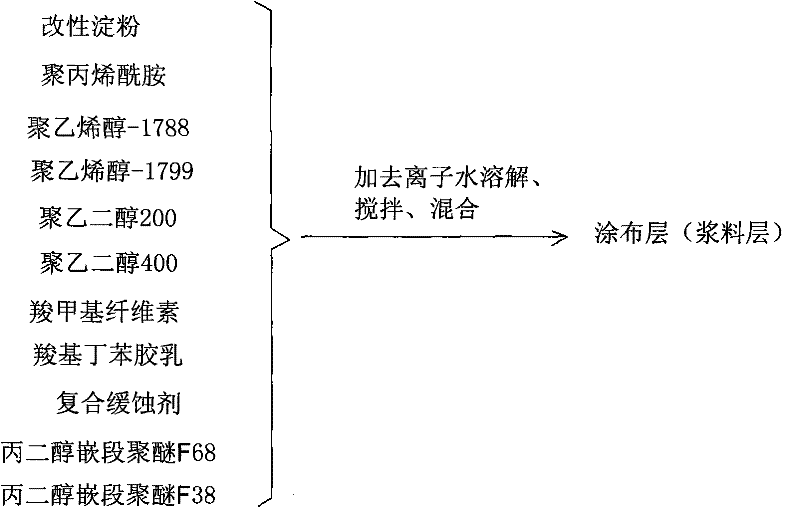

[0040] The components of the coating layer are:

[0041] Modified starch: 38%

[0042] Polyacrylamide: 2.5%

[0043] Polyvinyl alcohol 1788: 16%

[0044] Polyvinyl alcohol 1799: 22%

[0045] Polyethylene glycol 200: 3%

[0046] Macrogol 400: 4%

[0047] Carboxymethylcellulose: 3%

[0048] Carboxylated styrene-butadiene latex: 5%

[0049] Composite corrosion inhibitor: 2.5%

[0050] Propylene glycol block polyether F68: 1.5%

[0051] Propylene glycol block polyether F38: 2.5%

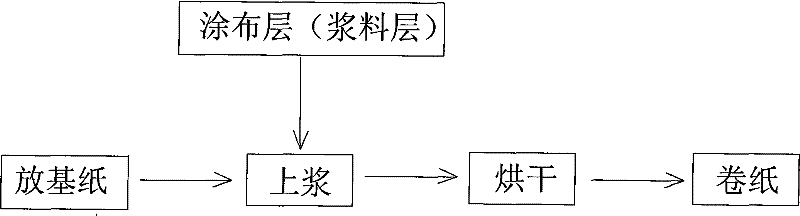

[0052] Add the above-mentioned modified starch to deionized water to prepare a modified starch solution; then add the above-mentioned polyvinyl alcohol, polyacrylamide, polyethylene glycol, carboxymethyl cellulose, and carboxylated styrene-butadiene latex to deionized water to dissolve, and then add Stir into the modified starch solution. Add composite corrosion inhibitor during the stirring process, use propylene glycol block polyether as defoaming agent for defoaming, stir until uniformly mixed...

Embodiment 2

[0054] Modified starch: 35%

[0055] Polyacrylamide: 2.5%

[0056] Polyvinyl alcohol 1788: 15%

[0057] Polyvinyl alcohol 1799: 26%

[0058] Macrogol 200: 2%

[0059] Macrogol 400: 5.5%

[0060] Carboxymethylcellulose: 4%

[0061] Carboxylated styrene-butadiene latex: 5.5%

[0062] Composite corrosion inhibitor: 2%

[0063] Propylene glycol block polyether F68: 1%

[0064] Propylene glycol block polyether F38: 1.5%

[0065] Add the above-mentioned modified starch to deionized water to prepare a modified starch solution; then add the above-mentioned polyvinyl alcohol, polyacrylamide, polyethylene glycol, carboxymethyl cellulose, and carboxylated styrene-butadiene latex to deionized water to dissolve, and then add Stir into the modified starch solution. Add composite corrosion inhibitor during the stirring process, use propylene glycol block polyether as defoaming agent for defoaming, stir until uniformly mixed, and the coating layer of pulp layer paper can be obtained;...

Embodiment 3

[0067] The components of the coating layer are:

[0068] Modified starch: 40%

[0069] Polyacrylamide: 2%

[0070] Polyvinyl alcohol 1788: 15%

[0071] Polyvinyl alcohol 1799: 20%

[0072] Polyethylene glycol 200: 4%

[0073] Macrogol 400: 4%

[0074] Carboxymethylcellulose: 3%

[0075] Carboxylated styrene-butadiene latex: 3%

[0076] Composite corrosion inhibitor: 3%

[0077] Propylene glycol block polyether F68: 2%

[0078] Propylene glycol block polyether F38: 3%

[0079] Add the above-mentioned modified starch to deionized water to prepare a modified starch solution; then add the above-mentioned polyvinyl alcohol, polyacrylamide, polyethylene glycol, carboxymethyl cellulose, and carboxylated styrene-butadiene latex to deionized water to dissolve, and then add Stir into the modified starch solution. Add composite corrosion inhibitor during the stirring process, use propylene glycol block polyether as defoaming agent for defoaming, stir until uniformly mixed, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com