Non-woven fabric and preparation method thereof

A non-woven, two-component technology, used in non-woven fabrics, textiles and papermaking, conjugated synthetic polymer rayon, etc. Difficulty of steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

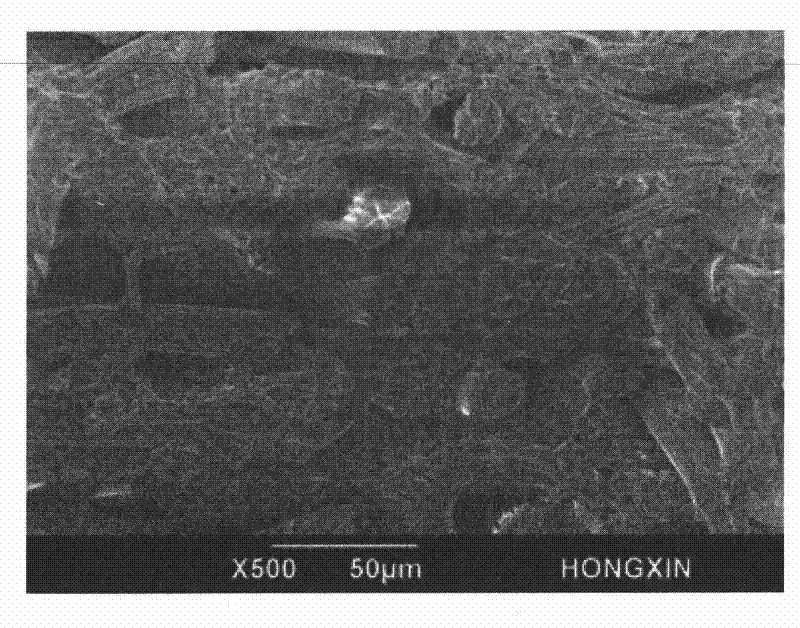

[0030] The preparation method of non-woven fabric provided by the invention comprises:

[0031] A two-component composite fiber is provided, wherein the two components in the two-component composite fiber are a polyester component and a polyamide component, and the two-component composite fiber includes a skeleton part arranged radially and filled in the skeleton The split part in the part, the two components respectively form the skeleton part and the split part, and the polyester component includes a flux that accounts for 0.1% to 4% of the total weight of the two-component composite fiber;

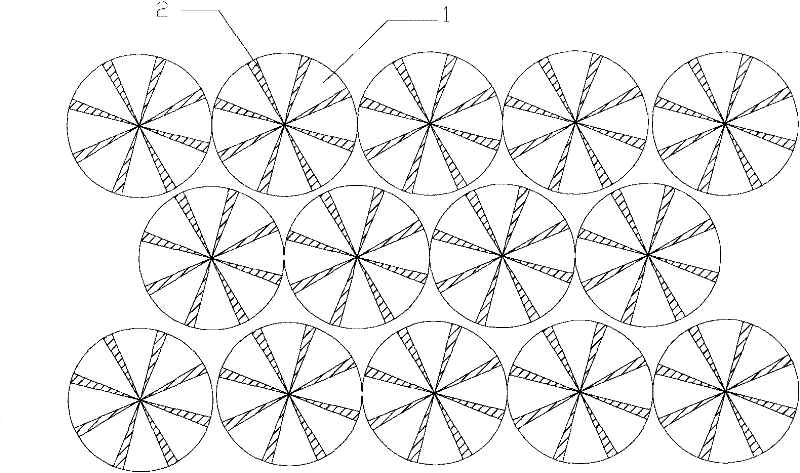

[0032] Opening and carding the bicomponent composite fiber, and then laying it into a fiber web;

[0033] Needling the web yields a nonwoven.

[0034] According to the present invention, the preparation of the two-component composite fiber is as follows: take polyester chips and flux as polyester components and put them into the first screw extruder for mixing. The mixing temperature i...

Embodiment 1

[0051] Take 22 parts of polyethylene terephthalate chips and dry them at 170°C, put them into a polyester spinning screw extruder to melt and knead at 280°C, and add 3 parts of flux during kneading , the flux is Polybutylene terephthalate ; 75 parts of polycaprolactam slices were dried at 85°C and put into a polyamide spinning screw extruder at 280°C for melting and kneading.

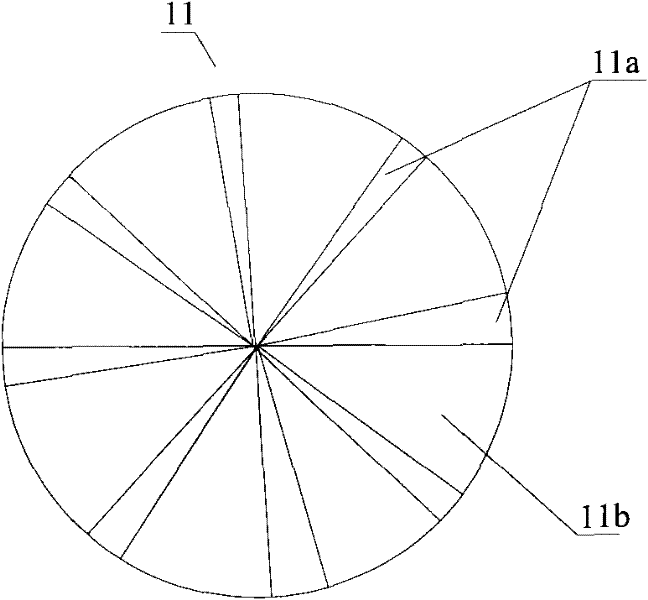

[0052] The mixed products of two screw extruders were subjected to figure 1 The 8-split spinneret is extruded to obtain as-spun fibers. The following examples all use this spinneret to extrude to obtain 8-split as-spun fibers. The lobes between the fiber skeletons are composed of polyethylene terephthalate and the lobes are polycaprolactam;

[0053] Then, the as-spun fibers are cooled and shaped by an annular cooling and blowing device, the cooling temperature is 22°C, and then oiled by oil tankers on both sides. The oil agent is 4wt% silicone emulsion, and the oil content of the fibers after oiling...

Embodiment 2 to Embodiment 5

[0056] Use polyester, flux, polyamide identical with embodiment 1 in above-mentioned four embodiments, concrete process parameter is shown in Table 2:

[0057] Measure the fiber performance of implementation 2 to embodiment 5, list in table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com