Antibacterial deodorizing insoles

A technology for insoles and surface pads, which is applied to insoles, deodorants, footwear, etc. It can solve the problems of easy sweating and poor air permeability of the feet, and achieve the effects of low cost, antibacterial and deodorizing functions, and good functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

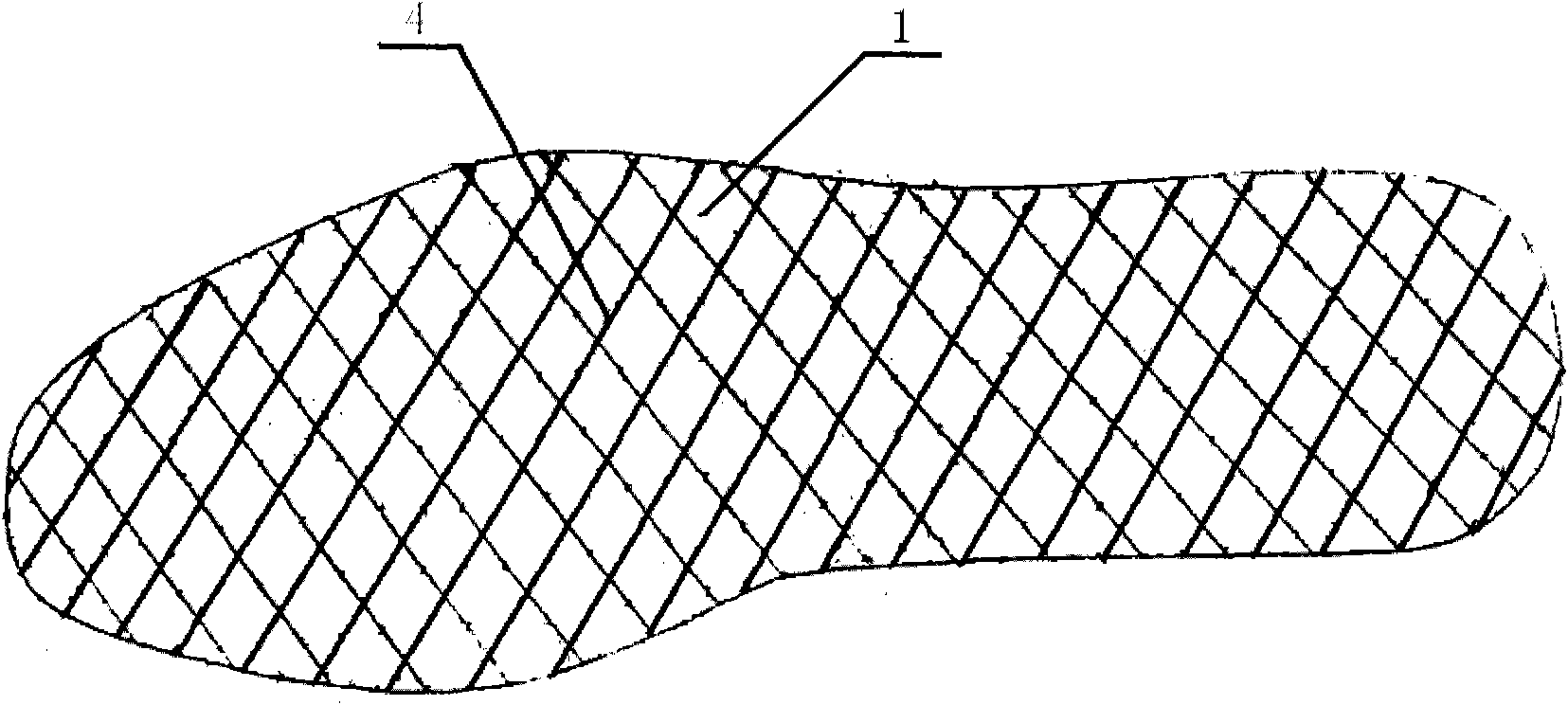

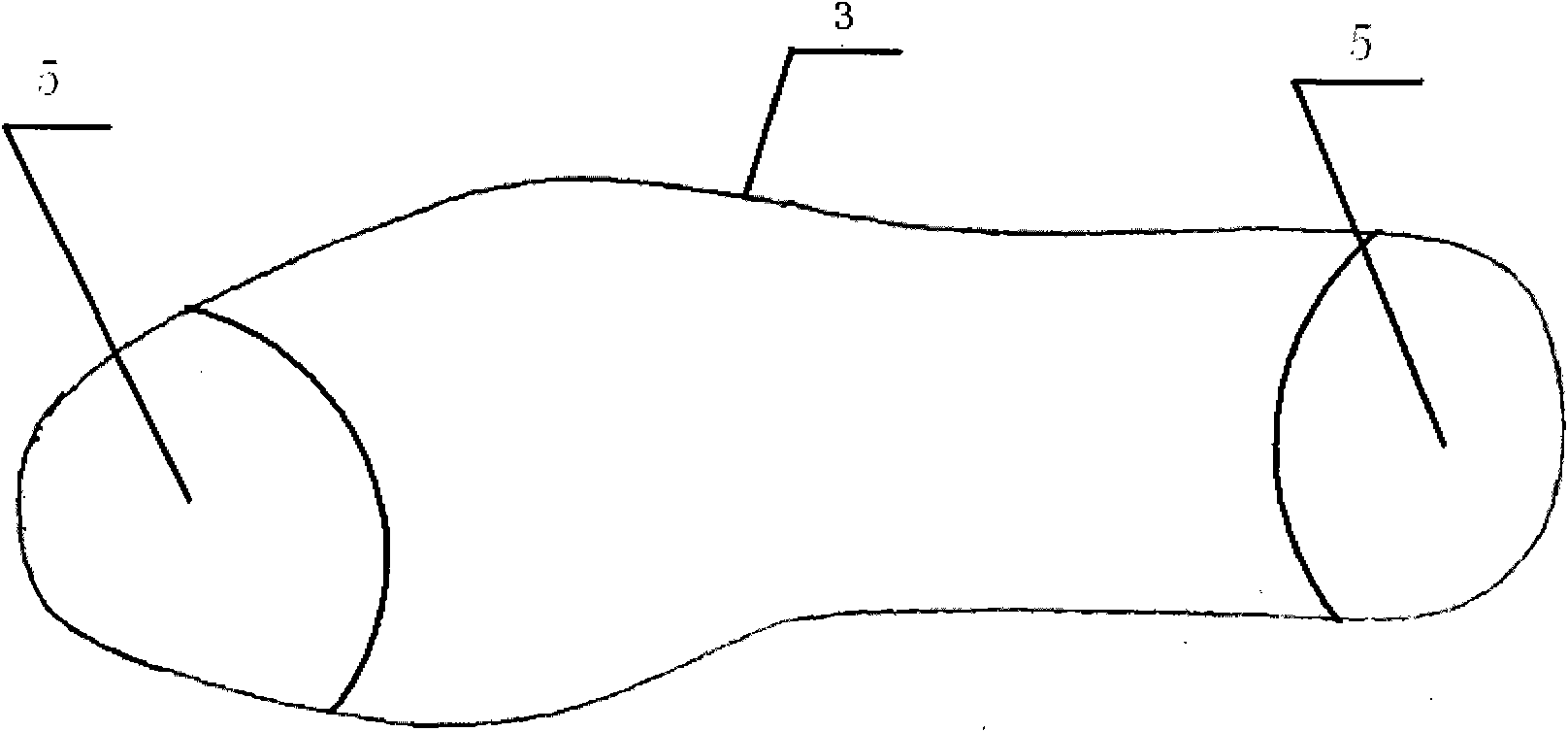

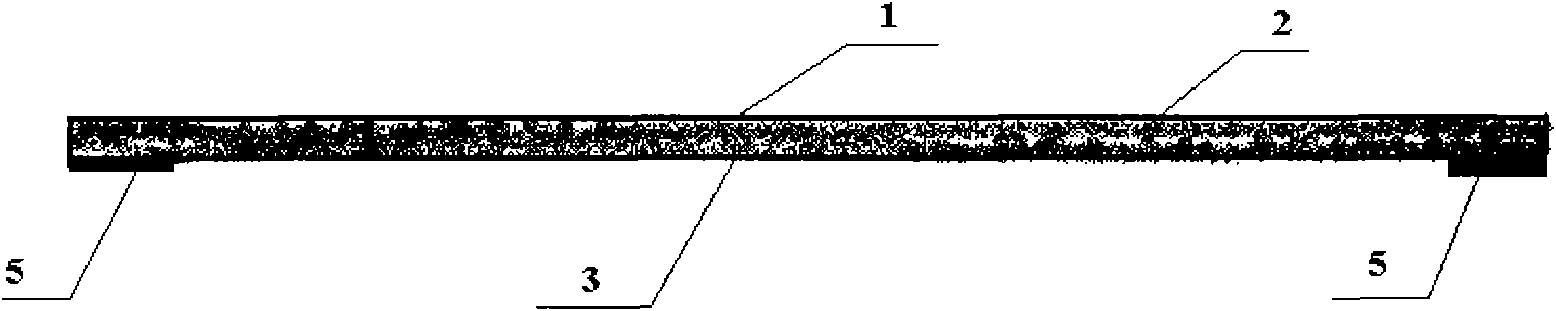

[0024] Such as Figure 1-3 As shown, the chlorine dioxide antibacterial and deodorant insole provided by the present invention consists of a pad surface 1, an antibacterial and deodorant filling layer 2 and a bottom 3. The cushion surface 1, the cushion bottom 3 and the filling layer 2 are fixedly connected, preferably, the cushion surface 1, the filling layer 2 and the cushion bottom 3 are fixed in a quilted grid shape with threads 4 .

[0025] The fabrics of the cushion surface 1 and the cushion bottom 3 are selected from breathable degradable materials, preferably chitin nonwoven fabrics.

[0026] The cushion surface 1 and the cushion bottom 3 are connected by suturing around the periphery, and the cushion surface 1, the filling layer 2 and the cushion bottom 3 are fixed in a grid shape with threads 4 .

[0027] Two back glues 5 are arranged at the bottom of the pad for fixing the insole on the sole. The two back glues 5 are located at the front and back of the bottom of ...

Embodiment 2

[0030] Basically the same as Example 1, the difference is that the preparation method of the filling layer 2 is composed of 10 g potassium dihydrogen phosphate and disodium hydrogen phosphate composition of 2 g of sodium chlorite solid powder and 2 g of citric acid and a pH value of 7.0 After uniform mixing, it is mixed into 30g of polyvinyl alcohol microfibers with an average fineness of 0.2dtex, and a filling layer is formed after blending and fluffy finishing.

Embodiment 3

[0032] Basically the same as Example 1, the difference is that the preparation method of the filling layer 2 is uniformly mixed with 2g of sodium chlorite solid powder and 0.5g of tartaric acid and 15g of acetic acid-sodium acetate composition with a pH value of 6.0, then mixed with Mixed into 50g of chitin microfibers with an average fineness of 0.3dtex, and formed a filling layer after blending and fluffy finishing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com