Blast furnace front real-time information monitoring system

A real-time information and monitoring system technology, applied in the monitoring system, the monitoring and monitoring of real-time information in front of the blast furnace, can solve the problem of affecting the reliability and real-time performance of instructions and data, and cannot grasp the production timing intuitively, accurately, timely and comprehensively. , single data source, etc., to achieve reliable performance, comprehensive functions, and real-time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

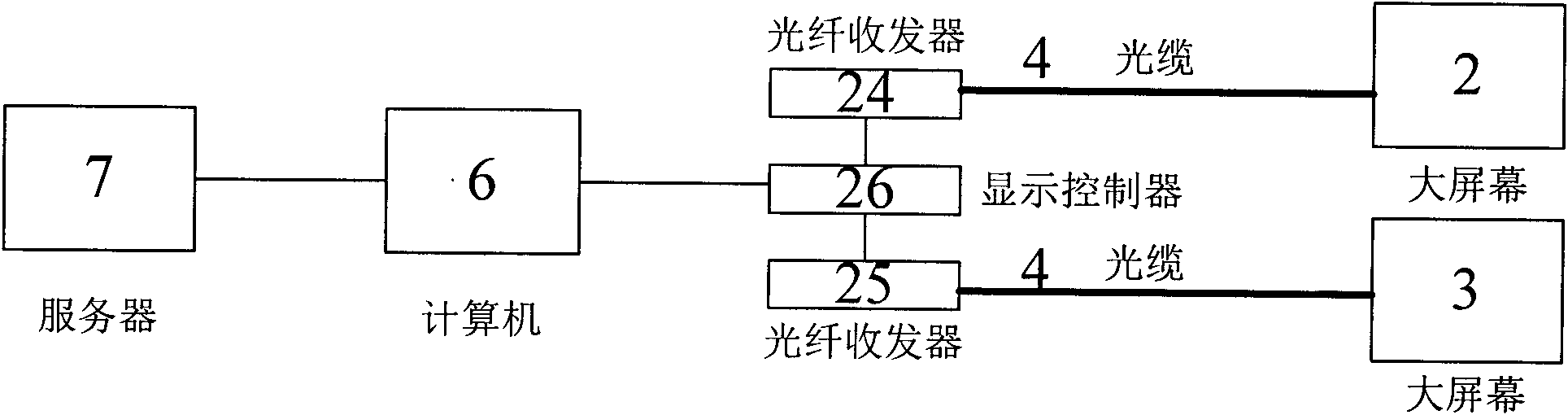

[0019] Embodiment 1. Blast furnace front real-time information monitoring system

[0020] The technical feature of this real-time information monitoring system in front of the blast furnace is that the real-time information monitoring system in front of the blast furnace is a real-time information monitoring system for the production and operation conditions in front of the blast furnace managed by a computer system. Automatic monitoring, surveillance, monitoring system of information. The specific structure of the real-time information monitoring system in front of the blast furnace in this example is given by Figure 1 to Figure 6 Jointly shown. figure 1 It is a structural diagram of the real-time information monitoring system in front of the blast furnace. figure 1Middle: 1 indicates the situation in front of the furnace, 2 is 1 of the large screen, such as displaying the blast furnace east tapping site, 3 is the large screen 2, such as displaying the blast furnace west t...

Embodiment 2

[0021] Embodiment 2. Blast furnace front real-time information monitoring system

[0022] The general structure of the real-time information monitoring system in front of the blast furnace is available Figure 1 to Figure 6 etc. jointly show that the difference between the real-time information monitoring system before the blast furnace furnace of this example and the real-time information monitoring system before the blast furnace furnace of embodiment one has: one, the specific number of the front-level computer n represented by 11 is such as 3, or 4, Or 5, or 6, or 7, or 8, or 9, or 10, or more than 10. Its two, the specific number of the programmable logic controller k of the preceding stage computer n (single) represented by 13 is as 2, or 3, or 4, or 5, or 6, or more than 6. Its three, the specific number of 1 of the acquisition unit of represented production site by 16 is as 2, or 3, or 4, or 5, or 6, or 7, or 8, or 9, or 10, or more than 10. Its four, 7 is the specif...

Embodiment 3

[0023] Embodiment 3. Blast furnace front real-time information monitoring system

[0024] The general structure of the real-time information monitoring system in front of the blast furnace is available Figure 1 to Figure 6 etc. jointly show that the real-time information monitoring system in front of the blast furnace of this example is different from the real-time information monitoring system in front of the blast furnace of embodiment one and embodiment two: the computer management system of the real-time information monitoring system in front of the blast furnace of this example is A blast furnace front real-time information monitoring system consisting of several blast furnaces and many computers, group control, joint control, and local area network. The rest of the real-time information monitoring system in front of the blast furnace of this example is the same as that described in Embodiment 1 and Embodiment 2, and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com