Super-large aluminum profile decorative louver and machining technology thereof

A technology of super-large aluminum profiles and processing technology, which is applied to building components, walls, buildings, etc., can solve the problems of aluminum alloy decorative louvers without heat insulation function, small space utilization rate, and lack of heat insulation, etc., to achieve beneficial The overall aesthetics, the design concept improvement, and the effect of improving the openness of the field of vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

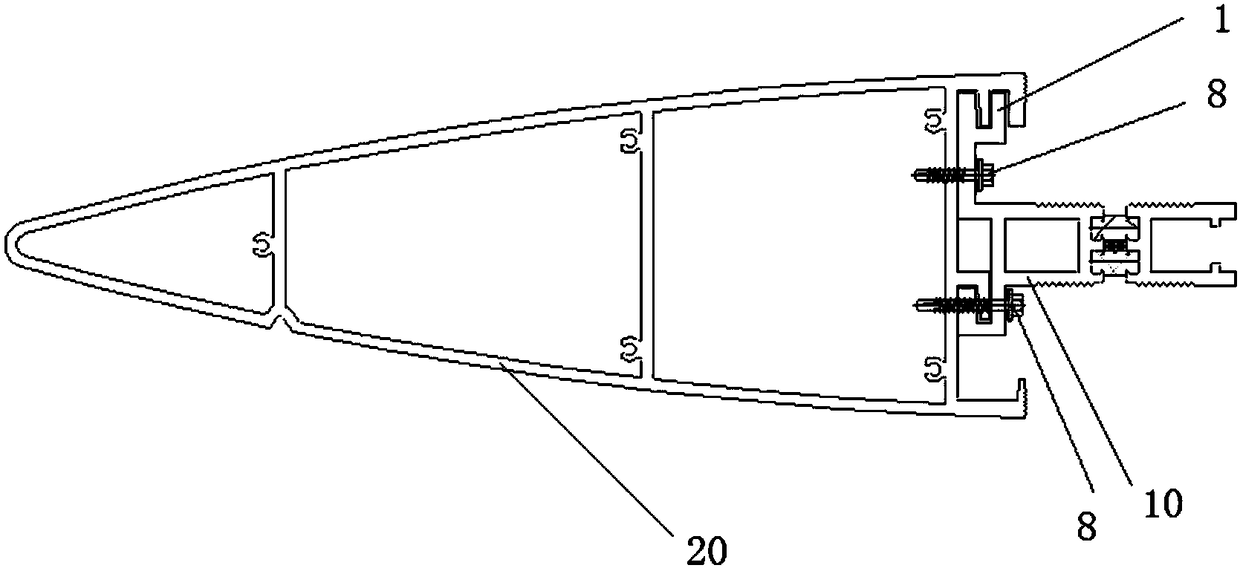

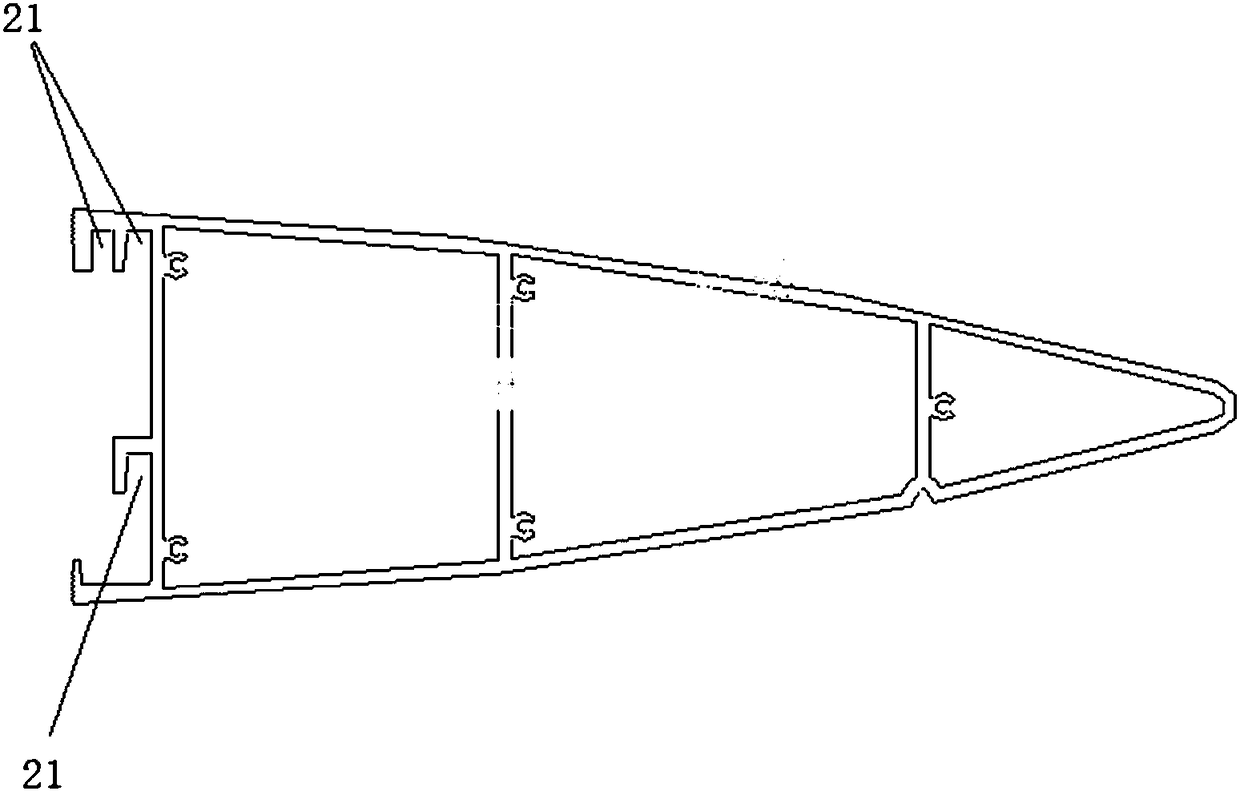

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a super large aluminum profile decorative louver (curtain wall decorative louver) of the present invention is formed by assembling (joining) two kinds of aluminum profiles (glue injection aluminum profile 10 and large louver aluminum profile 20). The large louver aluminum profiles 20 are strip-shaped aluminum profiles with a length of 9 meters.

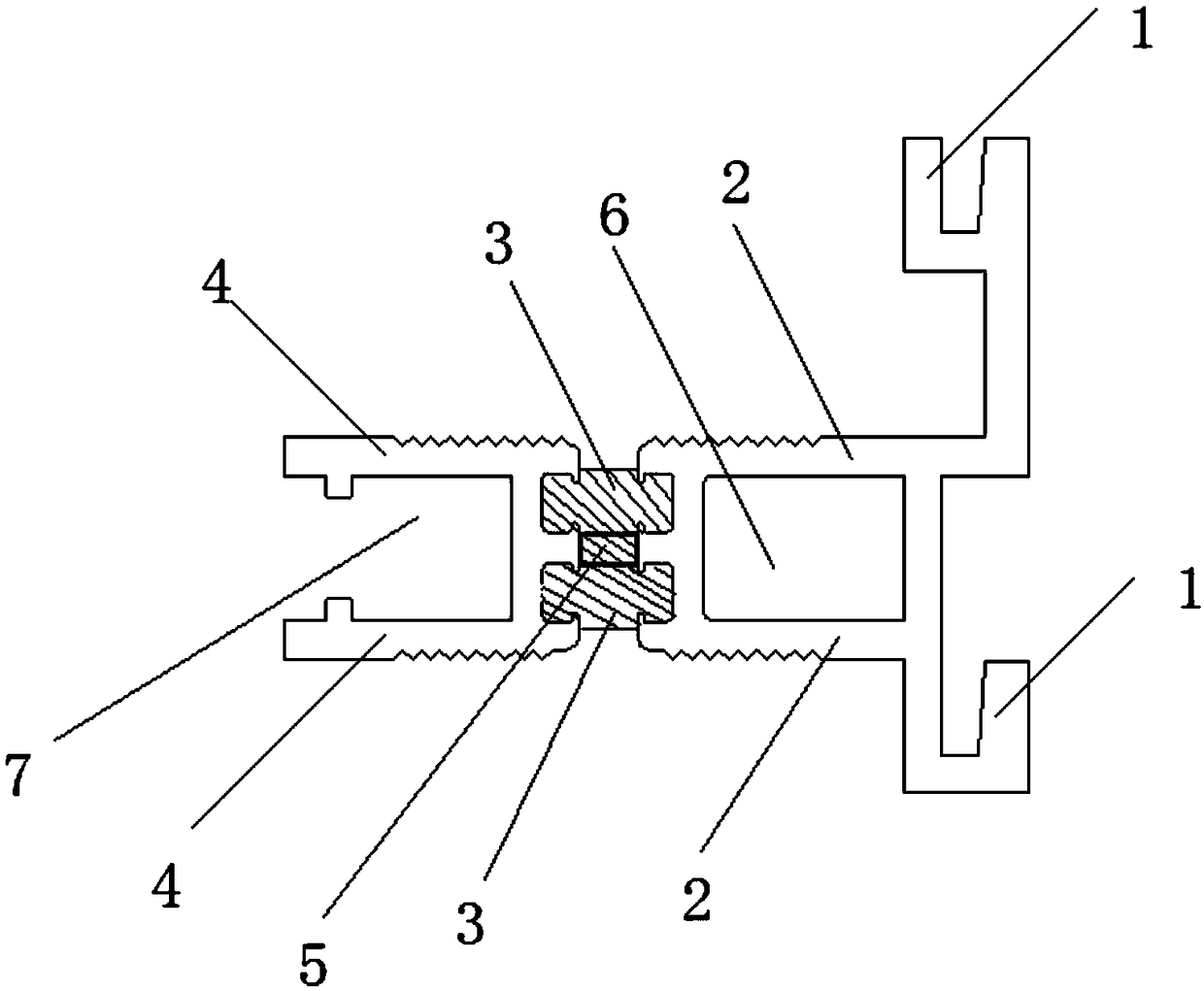

[0033] Such as figure 2 As shown, the glue-injected aluminum profile 10 (viewed from the cross-sectional view) includes: a connecting portion A 2 connecting the front end to the large louver aluminum profile, a connecting portion B 4 connecting the rear end to the curtain wall; connecting portion A and connecting portion B The gaps are connected through the intermediate connection; the intermediate connection is provided with a glue injection port 3, and the glue injection port 3 is filled with structural glue (the structural glue is a secondary polyurethane glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com