Liquid crystal membrane capable of being repeatedly processed and manufacturing method thereof

A technology of repeated processing and manufacturing methods, applied in optics, instruments, nonlinear optics, etc., can solve the problems of liquid crystal particles of different sizes, light-adjustable liquid crystal films that cannot be repeatedly bonded/processed, and light leakage, etc., to achieve good adhesion /Effect of processability, repeatability/processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

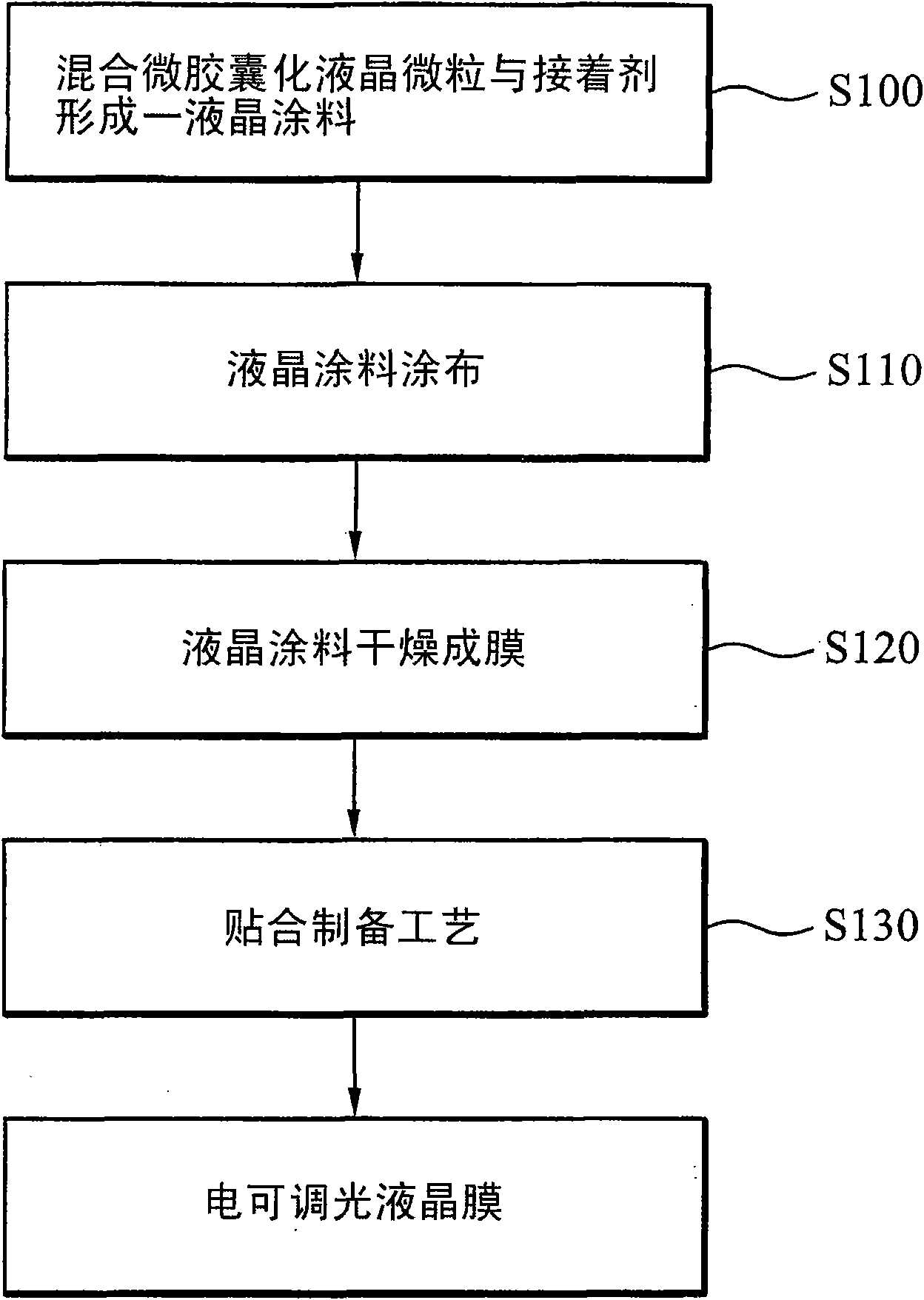

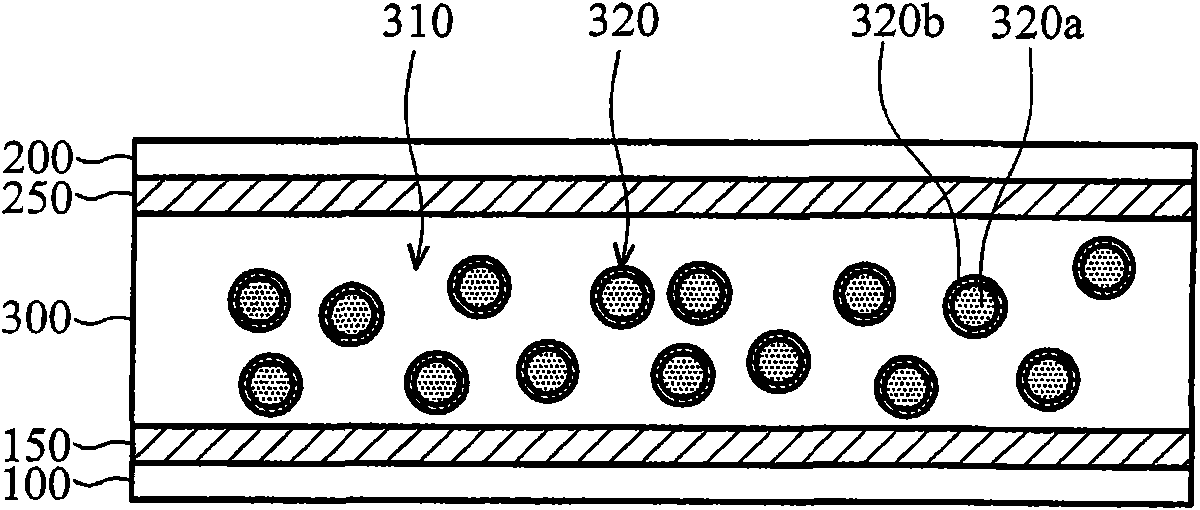

[0040] The microencapsulated liquid crystal particles of the synthesis example and 20% polyvinyl alcohol aqueous solution are uniformly mixed according to the ratio of 1:1.5 (weight ratio) at room temperature, and the liquid crystal coating can be prepared. The viscosity of the coating is 1000-1100cps (25°C), The solids content is about 42%. The weight average molecular weight of the polyvinyl alcohol used above is 27000-32000, the degree of polymerization is 550-650, and the sodium ion content is lower than 60ppm.

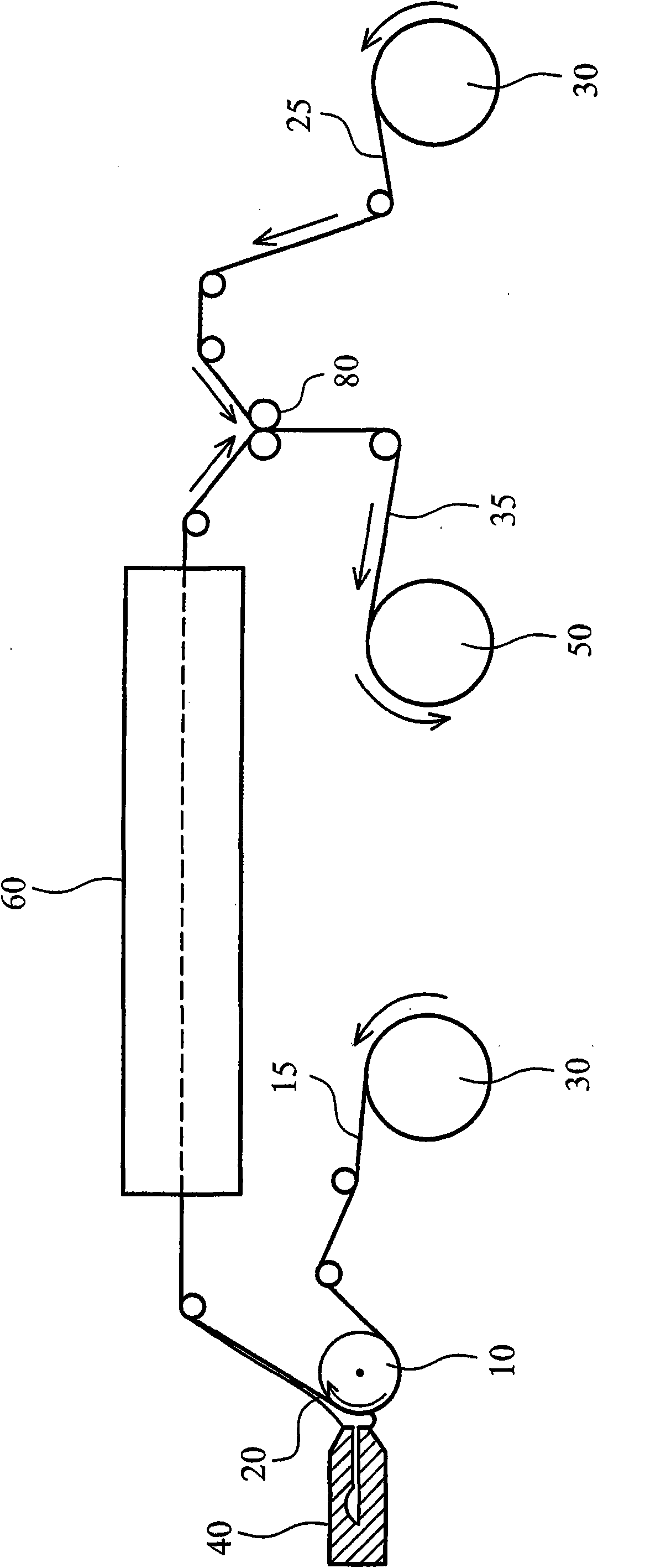

[0041] by figure 2 In the device shown, the PET-ITO film is coated with liquid crystal coating through the slit coating head (the coating width is 1.1 meters), and then enters the five-stage oven (temperature 40-90 ° C) to dry at a line speed of about 4 Move at a moving speed of m / min, and finally pass through a hot bonding wheel at about 100°C to bond with another PET-ITO film to continuously generate an electrically adjustable liquid crystal film with a thickn...

Embodiment 2

[0043] Same as Example 1, but wherein the liquid crystal coating is changed into microencapsulated liquid crystal particles and 20% polyvinyl alcohol aqueous solution, 20% polyurethane (PU) aqueous solution according to 1: 1.29: 0.21 (weight ratio) at room temperature uniformly mixed, the viscosity of coating It is 800-900cps (25°C), and the solid content is about 42%.

[0044] 【Optoelectronic Analysis of Electrically Dimmable Liquid Crystal Films】

[0045] The electro-dimmable glass produced by cutting the electro-dimmable liquid crystal film in rolls of Examples 1 and 2 and then going through the glass gluing process has a size of 1.1 meters in width and 3 meters in length. Measure its photoelectric property with clarity instrument (the instrument of EDTM company), its result is as follows Figure 5 As shown, the electrically adjustable liquid crystal film of Example 1 has high light transmittance (T%=65%@45V) which is better than the commercially available product Polyvisi...

Embodiment 3

[0056] With embodiment 1, but wherein use ion content to be lower than 60ppm respectively and ion content is higher than two kinds of 20% polyvinyl alcohol aqueous solutions of 3600ppm to prepare coating, and utilize scraper to coat on PET-ITO film, enter baking oven ( The temperature is 80-90°C) and dried for 7 minutes, and finally bonded with another PET-ITO film by a heat laminating machine at about 100°C to produce an electrically adjustable liquid crystal film with a thickness of 8 μm and 15 μm.

[0057] [Optoelectronic analysis of electrically tunable liquid crystal films made of 20% PVA aqueous solutions with different ion contents]

[0058] Measure the light transmittance of the electric dimmable film sample that uses low ion content (≤60ppm) and high ion content (≥3600ppm) 20% polyvinyl alcohol aqueous solution to make of embodiment 3 to the voltage relation figure, and its result is as follows Figure 10 As shown, the light transmittance of the electric dimmable film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com