Method for measuring sulfur content in iron ore

A determination method and technology for sulfur content, applied in material excitation analysis, thermal excitation analysis, etc., can solve the problems of cumbersome methods and many steps, and achieve the effect of ensuring sensitivity and accuracy, less reagents, and eliminating the limitation of detection range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Weigh 0.1g (sampling volume accurate to less than 0.0002g) of iron ore to be tested with a particle size of less than 0.100mm, dried and cooled to room temperature with a sulfur content greater than 0.5%, and conduct a blank test along with the sample. Then put the sample in a polytetrafluoroethylene high-pressure digestion tank dedicated to microwave ovens, add 6mL of aqua regia, and start the program on the microwave oven for microwave digestion to ensure that the sample is completely decomposed. After the microwave digestion is completed, cool to room temperature, and then set the volume in a 50mL volumetric flask.

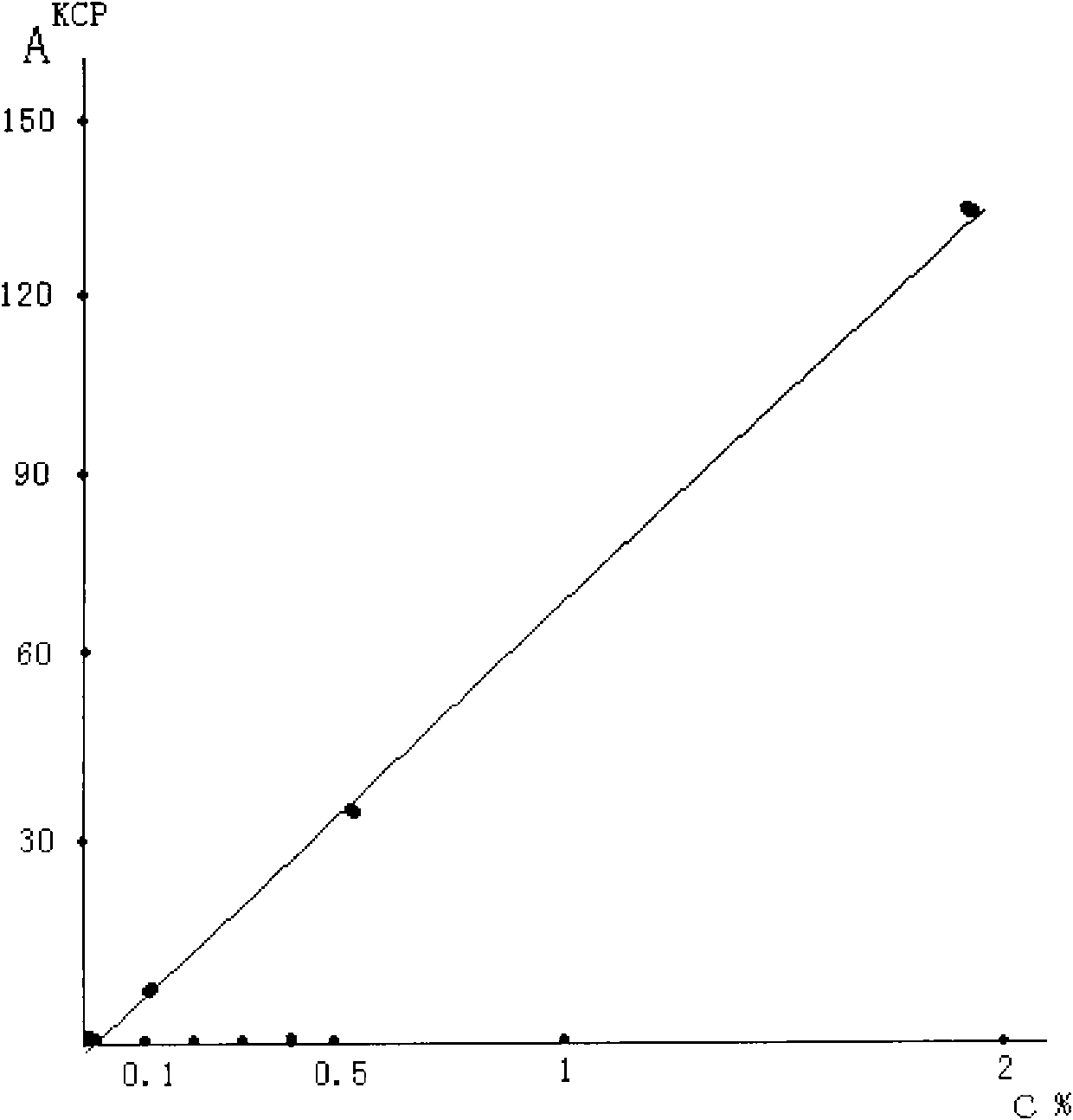

[0022] (2) Prepare sulfur standard solutions with a concentration of 25 μg / mL, 50 μg / mL, 100 μg / mL, 200 μg / mL, and 500 μg / mL with high-grade pure potassium sulfate, then weigh five parts of 0.06 g of high-purity iron, and use 6 mL of aqua regia After heating and dissolving on the electric heating plate, transfer it into a 50mL volumetric flask, and a...

Embodiment 2

[0027] (1) Weigh 1.0g (sampling amount is accurate to an error of less than 0.0002g) of an iron ore sample to be tested with a particle size of less than 0.100mm, dried and cooled to room temperature with a sulfur content greater than 0.0005%, and conduct a blank test along with the sample. Then put the sample in a PTFE high-pressure digestion tank dedicated to microwave ovens, add 12mL of aqua regia, and then add 3mL of hydrofluoric acid to speed up the dissolution of the sample, and then start the program on the microwave oven for microwave digestion to ensure that the sample is decomposed completely. After the microwave digestion is completed, cool to room temperature, and then set the volume in a 50mL volumetric flask.

[0028] (2) Three or more iron ore standard substances or standard samples whose sulfur content includes the sulfur content of the sample are dissolved with the same sample dissolution method as in step (1), and then used inductively coupled plasma emission...

Embodiment 3

[0032] (1) Weigh 0.5g (sampling amount is accurate to an error of less than 0.0002g) iron ore sample to be tested with a particle size of less than 0.100mm, dried and cooled to room temperature with a sulfur content greater than 0.0005%, and conduct a blank test together with the sample. Then put the sample in a PTFE high-pressure digestion tank dedicated to microwave ovens, add 6mL of aqua regia, and then add 2mL of hydrofluoric acid to speed up the dissolution of the sample, and then start the program on the microwave oven for microwave digestion to ensure that the sample is decomposed completely. After the microwave digestion is completed, cool to room temperature, and then set the volume in a 50mL volumetric flask.

[0033](2) Prepare sulfur standard solutions with a concentration of 25 μg / mL, 50 μg / mL, 100 μg / mL, 200 μg / mL, and 500 μg / mL with high-grade pure potassium sulfate, then weigh five parts of 0.20 g of high-purity iron, and use 6 mL of aqua regia After heating a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com