Cold bending thin-wall steel beam column node

A technology of cold-formed thin-walled steel and beam-column joints, which is applied in the direction of buildings and building structures, can solve the problems of reducing joint stiffness and plastic deformation capacity, reducing structural ultimate bearing capacity, and reducing column and plate ductility, etc., and achieves seismic resistance. Superior performance, improved ultimate bearing capacity and improved ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

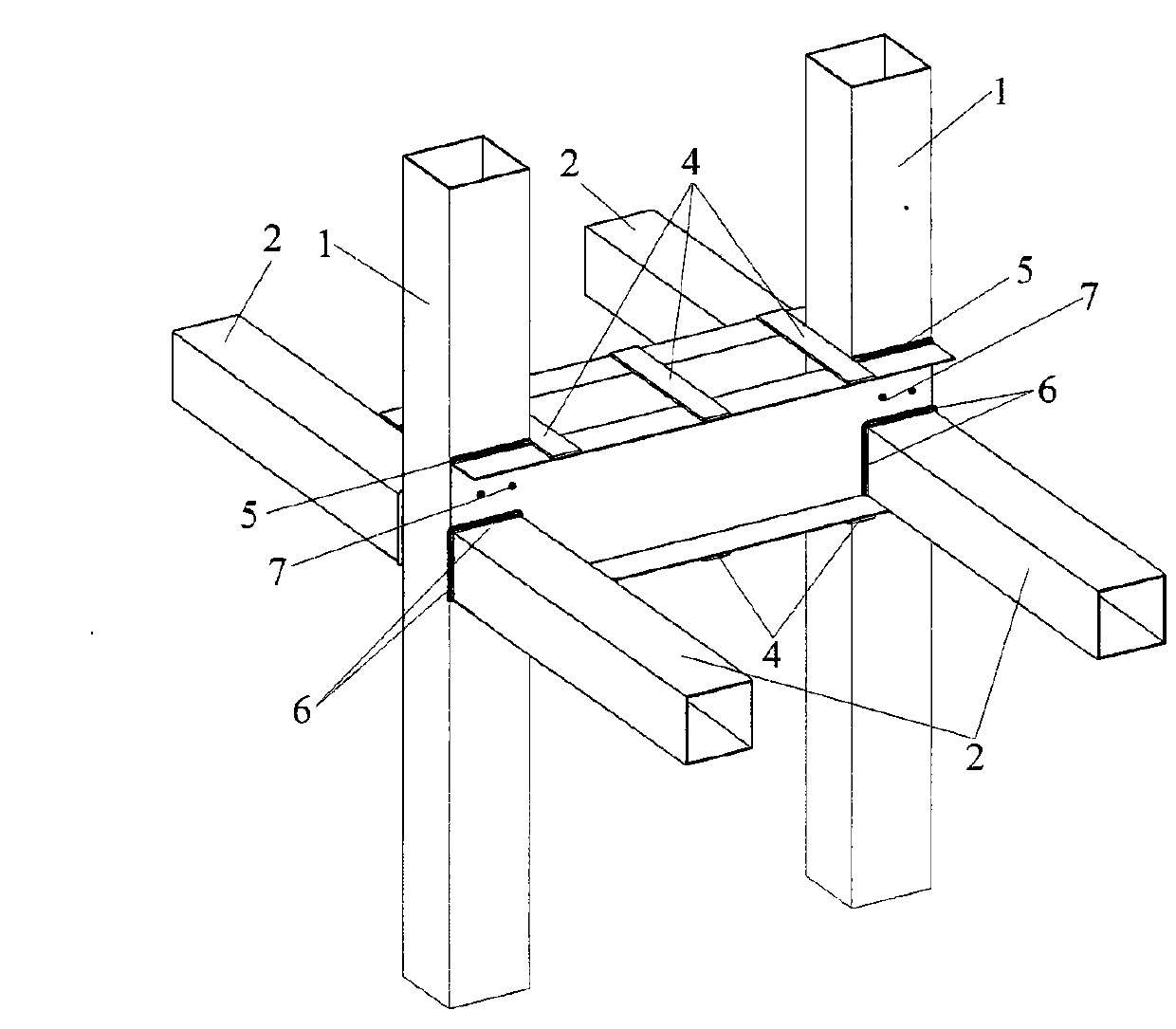

[0023] Embodiment 1 (see figure 1 ): The present invention is a kind of cold-formed thin-walled steel center column node related to structural engineering. It consists of square steel pipe columns 1, square steel pipe beams 2, C-shaped steel beams 3, trim plates 4, fillet welds 5 and 6, and self-tapping screws 7. Two square steel pipe columns 1 connect two C-shaped steel beams 3 on both sides through eight fillet welds 5; six panels 4 are welded on the upper and lower flange surfaces of the C-shaped steel beam 3, and are distributed on the C-shaped steel beam 3 mid-span and both ends; four square steel pipe girders 2 and C-shaped steel girder 3 are welded to the lower flange of C-shaped steel girder 3 through fillet welds 6 (when the web height of C-shaped steel girder 3 exceeds the specification requirements, the The self-tapping screw 7 connects the square steel pipe column 1 with the transverse C-shaped steel beam 3). In this type of node, the C-shaped steel beam 3 is arr...

Embodiment 2

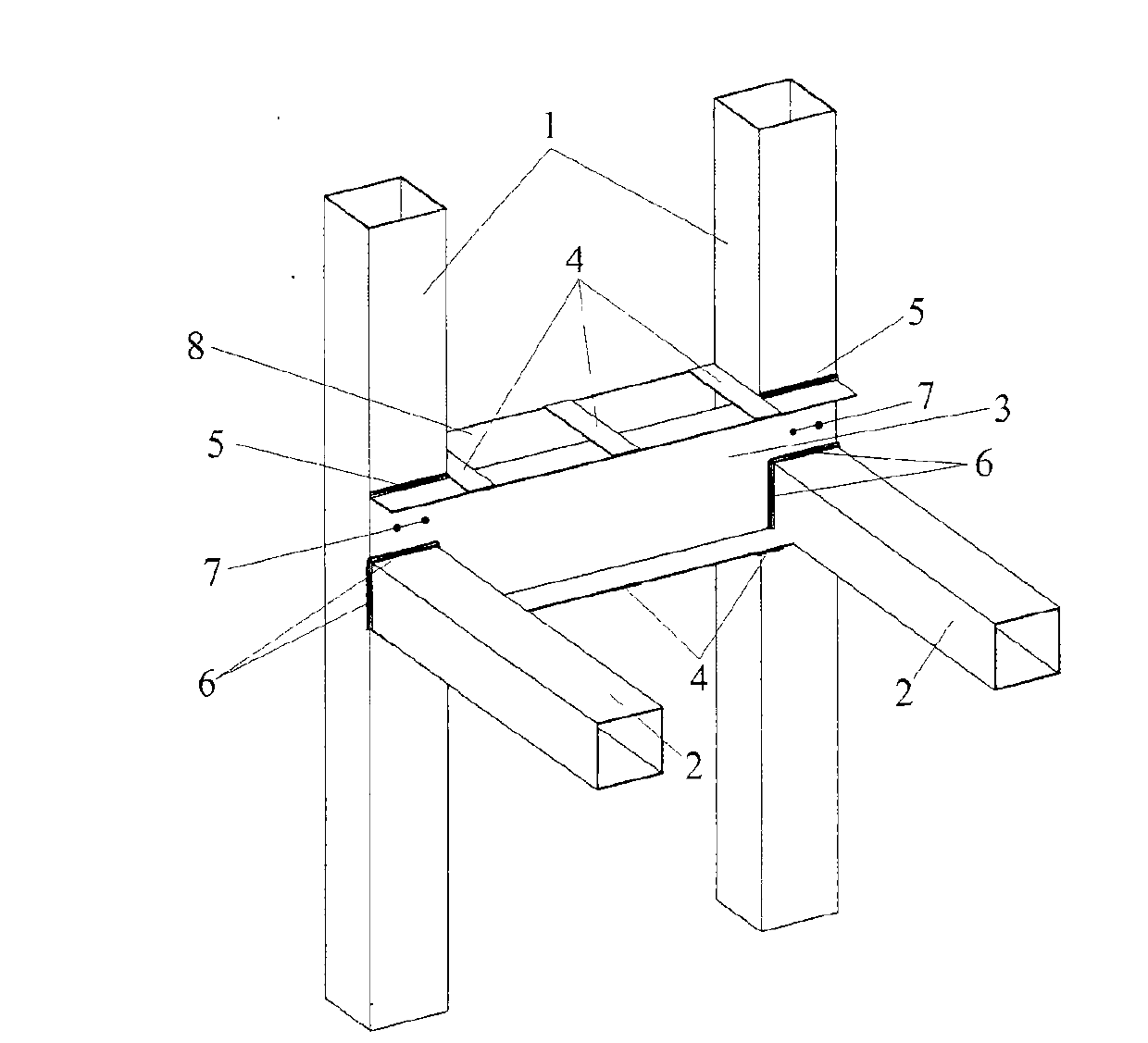

[0024] Embodiment 2 (see figure 2 , image 3 ): The present invention is a kind of cold-formed thin-walled steel side column node related to structural engineering. It consists of square steel pipe columns 1, square steel pipe beams 2, C-shaped steel beams 3, steel plates 8, trim plates 4, fillet welds 5, fillet welds 6, and self-tapping screws 7. Two square steel pipe columns 1 and a C-shaped steel beam 3 are welded on one side through four fillet welds 5, and two square steel pipe columns 1 and a steel plate 8 are welded on the other side through four fillet welds 5; the C-shaped steel beam 3 and the upper and lower surfaces of the steel plate 8 are welded with six panels 4, evenly distributed between the square steel pipe columns 1; two square steel pipe beams 2 are welded to the lower flange of the C-shaped steel beam 3 through the fillet weld 6 (when the steel plate When the height of the web plate of the C-shaped steel beam 3 exceeds the specification requirement, sel...

Embodiment 3

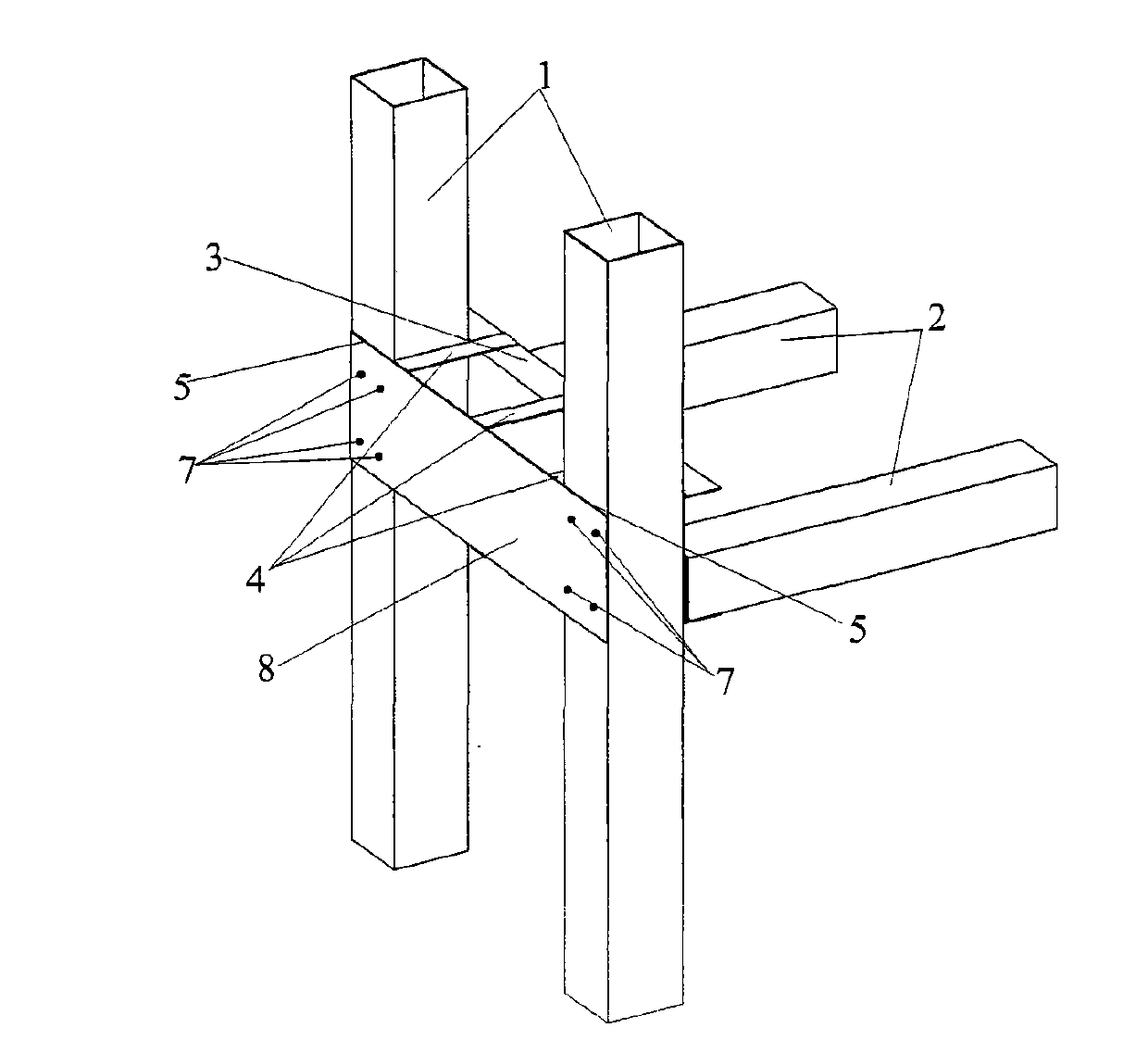

[0025] Embodiment 3 (see Figure 4 , Figure 5 ): The present invention is a kind of cold-formed thin-walled steel corner column joint related to structural engineering. It consists of square steel pipe columns 1, square steel pipe beams 2, C-shaped steel beams 3, steel plates 8, trim plates 4, fillet welds 5, fillet welds 6, and self-tapping screws 7. A square steel pipe column 1 and a C-shaped steel beam 3 are welded on one side through a fillet weld 5, and a square steel pipe column 1 and a steel plate 8 are welded on the other side through a fillet weld 5; the C-shaped steel beam 3 and the steel plate 8 The upper and lower surfaces are welded with panel 4, and the C-shaped steel beam 3 and the square steel pipe girder 2 are welded to the lower flange of the C-shaped steel beam 3 through the fillet weld 6 (when the height of the web of the steel plate 8 and the C-shaped steel beam 3 exceeds the specification requirements , can adopt self-tapping screw 7 to connect it with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com