Daily ceramic vessel with healthcare function and manufacture method thereof

A technology of ceramics and utensils, which is applied in the field of daily-use ceramic utensils with health care functions and its manufacturing field. It can solve the problems of fast heat transfer, no appreciation, poor heat preservation and heat insulation, etc., achieve high collection value, improve artistic appreciation, The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

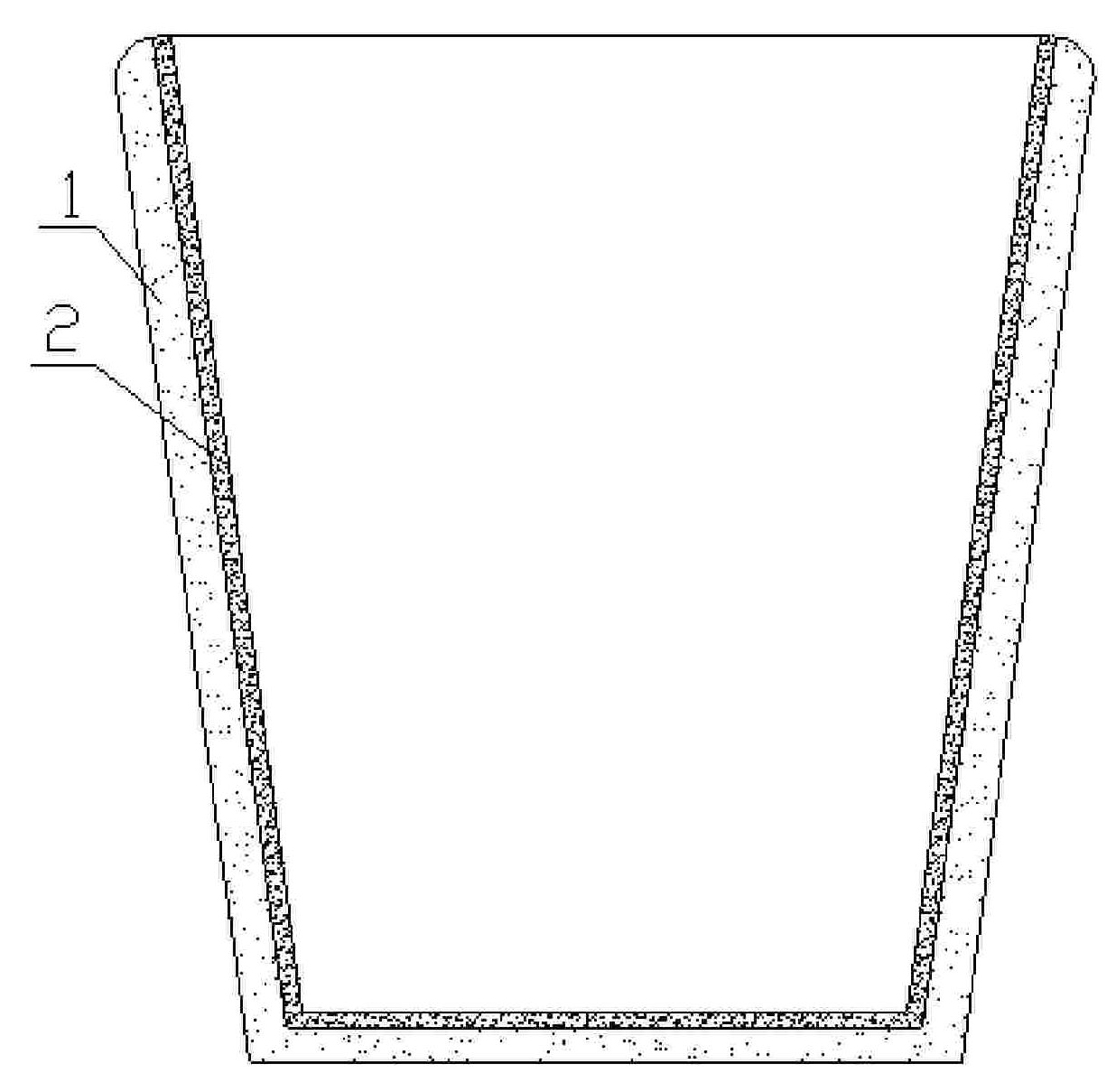

[0015] Referring to the accompanying drawings, this embodiment includes a ceramic substrate 1 whose inner surface is covered with a mixture coating 2 of silver oxide and bismuth oxide.

[0016] In the mixture of silver oxide and bismuth oxide, the weight ratio of silver oxide to bismuth oxide is 98:2.

[0017] Manufacturing method: add rosin water equivalent to 25wt% of the weight of the mixture powder of silver oxide and bismuth oxide to the mixture powder of silver oxide and bismuth oxide, adjust it into a slurry, apply it evenly on the surface of the ceramic vessel substrate, and place it in a kiln. Gradually raise the temperature to 820°C over 2.5 hours, keep the temperature for half an hour, then stop heating and cool to room temperature. The inner surface luster of the fired product is almost indistinguishable from the silver metallic luster.

Embodiment 2

[0019] This embodiment includes a ceramic substrate, the inner and outer surfaces of the ceramic substrate are covered with a mixture coating of silver oxide and copper oxide.

[0020] In the mixture of silver oxide and copper oxide, the weight ratio of silver oxide to copper oxide is 97:3.

[0021] The production method is as follows: add rosin water equivalent to 20wt% of the weight of the mixture powder of silver oxide and copper oxide to the mixture powder of silver oxide and selenium oxide, adjust it into a slurry, apply it evenly on the inner and outer surfaces of the ceramic vessel base, and place it in a kiln During 3 hours, the temperature was gradually increased to 830°C, and the temperature was maintained for 20 minutes, then the heating was stopped and cooled to room temperature. There is almost no difference between the internal and external surface gloss of the fired product and the silver metallic luster.

Embodiment 3

[0023] This embodiment includes a ceramic substrate, the inner and outer surfaces of the ceramic substrate are covered with a mixture coating of silver oxide and calcium oxide.

[0024] In the mixture of silver oxide and calcium oxide, the weight ratio of silver oxide to calcium oxide is 99:1.

[0025] The production method is as follows: add rosin water equivalent to 28wt% of the weight of the mixture powder of silver oxide and calcium oxide to the mixture powder of silver oxide and selenium oxide, adjust it into a slurry, evenly apply it on the inner and outer surfaces of the ceramic vessel base, and place it in a kiln During 2 hours, gradually increase the temperature to 810°C, keep the temperature for 40 minutes, then stop heating and cool to room temperature. There is almost no difference between the internal and external surface gloss of the fired product and the silver metallic luster.

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com