Perovskite structure material and preparation method thereof

A technology of perovskite structure and metal elements, applied in structural parts, battery pack parts, circuits, etc., can solve the problems of insufficient stability of shell materials, and achieve the effect of excellent stability and excellent corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

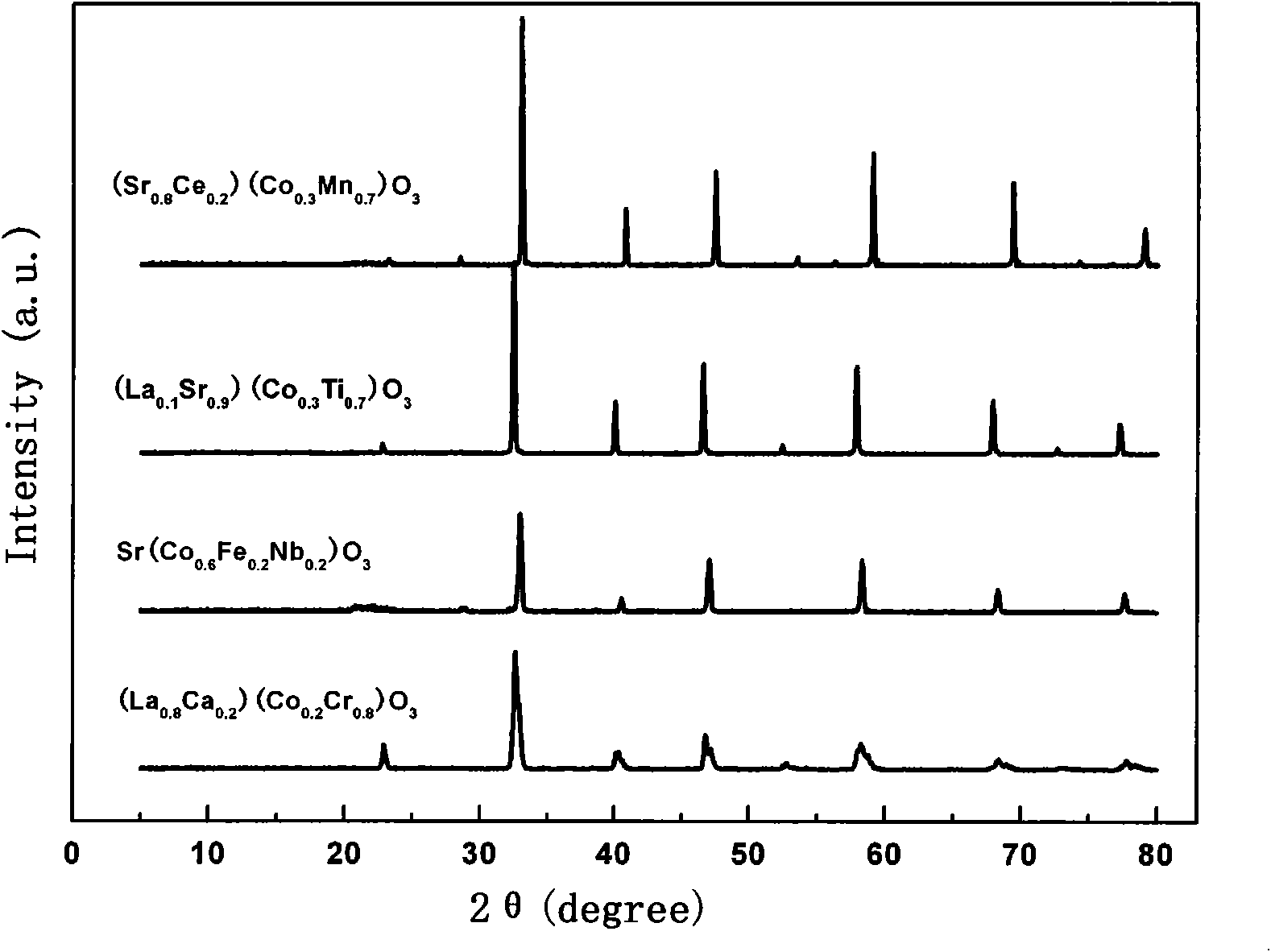

[0034] Perovskite structure material La 0.1 Sr 0.9 co 0.3 Ti 0.7 o 3 Preparation of (LSCT):

[0035] Press La 0.1 Sr 0.9 co 0.3 Ti 0.7 o 3 The stoichiometric ratio, each weighing an appropriate amount of La 2 o 3 ,Co 2 o 3 , SrCO 3 ,TiO 2 , mixed by ball milling in alcohol medium for 3 hours, dried at 60°C for 24 hours, raised to 1150°C at a rate of 2°C / min, kept for 10 hours, and cooled with the furnace. The obtained powder is granulated by adding 1% polyvinyl butyral (PVB) binder of the powder weight, and the particle size of the powder is controlled to be 100-400 meshes, pressed and molded, and the temperature rises to 1330 at a rate of 2° C. / min. ℃ sintering for 1 hour.

Embodiment 2

[0037] Perovskite structure La 0.9 Ca 0.1 co 0.2 Cr 0.8 o 3 Preparation of (LCCC):

[0038] Press La 0.9 Ca 0.1 co 0.2 Cr 0.8 o 3 The stoichiometric ratio, each weighing an appropriate amount of La 2 o 3 ,Co 2 o 3 , CaCO 3 , Cr 2 o 3 , mixed by ball milling in alcohol medium for 3 hours, dried at 60°C for 24 hours, raised to 1100°C at a rate of 2°C / min, kept for 10 hours, and cooled with the furnace. The obtained powder is granulated by adding 1% polyvinyl butyral (PVB) binder of the powder weight, and the particle size of the powder is controlled to be 100 to 400 meshes, pressed and molded, and the temperature rises at a rate of 2° C. / min. Sinter at 1500°C for 1 hour.

Embodiment 3

[0040] Perovskite structure SrCo 0.6 Fe 0.2 Nb 0.2 o 3 (SCFN) preparation:

[0041] Press SrCo 0.6 Fe 0.2 Nb 0.2 o 3 The stoichiometric ratio, each weighed an appropriate amount of SrCO 3 ,Co2 o 3 , Fe 2 o 3 , Nb 2 o 5 , mixed by ball milling in alcohol medium for 3 hours, dried at 60°C for 24 hours, raised to 1200°C at a rate of 2°C / min, kept for 10 hours, and cooled with the furnace. The obtained powder is granulated by adding 1% polyvinyl butyral (PVB) binder of the powder weight, and the particle size of the powder is controlled to be 100 to 400 meshes, pressed and molded, and the temperature rises at a rate of 2° C. / min. Sinter at 1300°C for 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com