Tungsten-doped vanadium dioxide powder material and preparation method thereof

A technology of vanadium dioxide and powder materials, applied in vanadium oxide and other directions, can solve the problems of expensive preparation of raw materials, difficult to control, complicated preparation methods, etc., and achieve the effects of simple process, easy acquisition and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

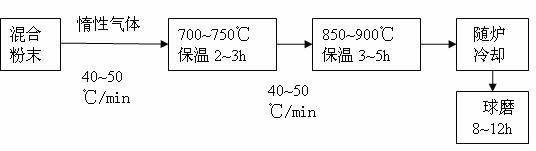

[0029] The preparation method of tungsten-doped vanadium dioxide powder material of the present invention, as figure 1 As shown, the specific steps are as follows:

[0030] Step 1: Use a photoelectric balance to weigh 2.97%-3.19% reducing agent, 0%-6.89% industrial pure tungsten trioxide, and the balance is industrial pure vanadium pentoxide. The sum of the mass percentages of the above components is 100 %, mix uniformly on the mixer, and the scheduled mixing time is 4-6 hours. In order to prevent the powder from agglomerating and achieve the effect of full mixing and uniformity, it is necessary to add a certain amount of stainless steel balls to the mixed powder, and the ratio of balls to materials is about 2:1.

[0031] Step 2: Transfer the uniformly mixed powder obtained in step 1 into a ceramic reaction vessel, and then put it into a tube sintering furnace. First, open the gas flow valve, remove the air in the tubular sintering furnace, and then start the heating reactio...

Embodiment 1

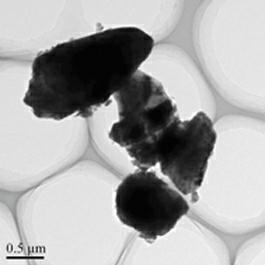

[0034] 5gV 2 o 5 Powder and 0.165g C powder are mixed and mixed on the mixer for 4 hours, then loaded with pre-cleaned Al 2 o 3 reaction vessel, and then put it into a tube sintering furnace. One end of the tube sintering furnace is fed with N 2 The other end is connected with clarified lime water through a rubber tube. First open the ventilation valve, and after 30 minutes, turn on the heating switch of the tubular sintering furnace to start heating. Close the vent valve when it drops to around 100°C. XRD analysis results show that the reduction product is monoclinic phase VO 2 , higher purity. Such as Figure 4 As shown, it can be seen from the DSC curve that the phase transition point of the product is around 67.04°C, which is similar to that of the monoclinic phase VO 2 The phase transition temperature of 68 °C is in good agreement, which further proves the correctness of the XRD analysis results. The agglomeration of the reduced powder taken out from the tube si...

Embodiment 2

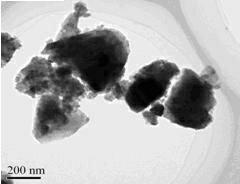

[0036] 5gV 2 o 5 Powder, 0.165gC and 0.40gWO 3 The powder (where the W / V atomic ratio is 3%) was uniformly mixed on the mixer for 5 hours, and then filled with pre-cleaned Al 2 o 3 reaction vessel, and then put it into a tube sintering furnace. One end of the tube sintering furnace is fed with N 2 The other end is connected with clarified lime water through a rubber tube. First open the ventilation valve, and after 30 minutes, turn on the heating switch of the tubular sintering furnace to start heating. Close the vent valve when it drops to around 100°C. XRD analysis results show that the reduction product is monoclinic phase VO 2 , there is no WO 3 The diffraction peaks of W 6+ Already dissolved in VO 2 lattice thus forming V 1-x W x o 2 solid solution. Such as Figure 5 As shown, it can be seen intuitively from the DSC curve that the phase transition temperature of the product has dropped to around 6.48°C, which further confirms that W 6+ The purpose of dopin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com