Precision forging method of titanium alloy blade

A precision forming and titanium alloy technology, which is applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of long manufacturing cycle, large blade fluctuation, and high manufacturing cost, and achieve low raw material consumption and comprehensive Good performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Coat the glass lubricant on the surface of the pre-forged blade forging, the thickness of the glass lubricant is 0.3mm, and then heat the blade forging to 50°C below the transformation point of the blade forging, and keep it warm for 15 minutes.

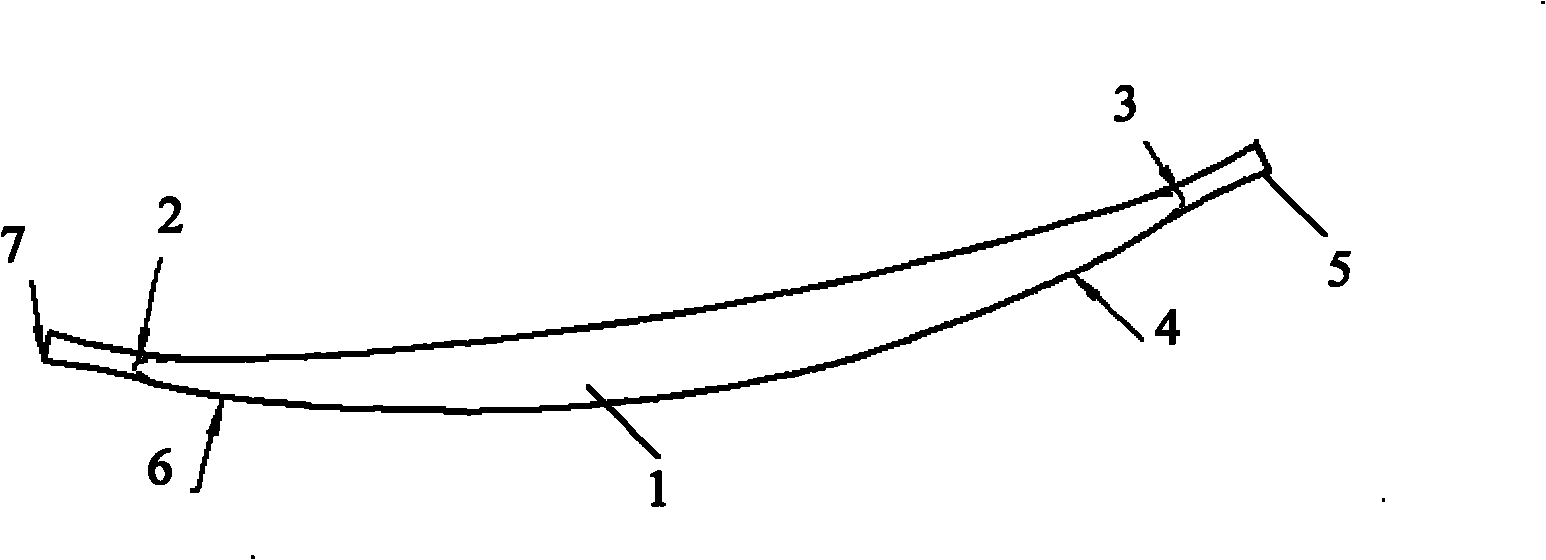

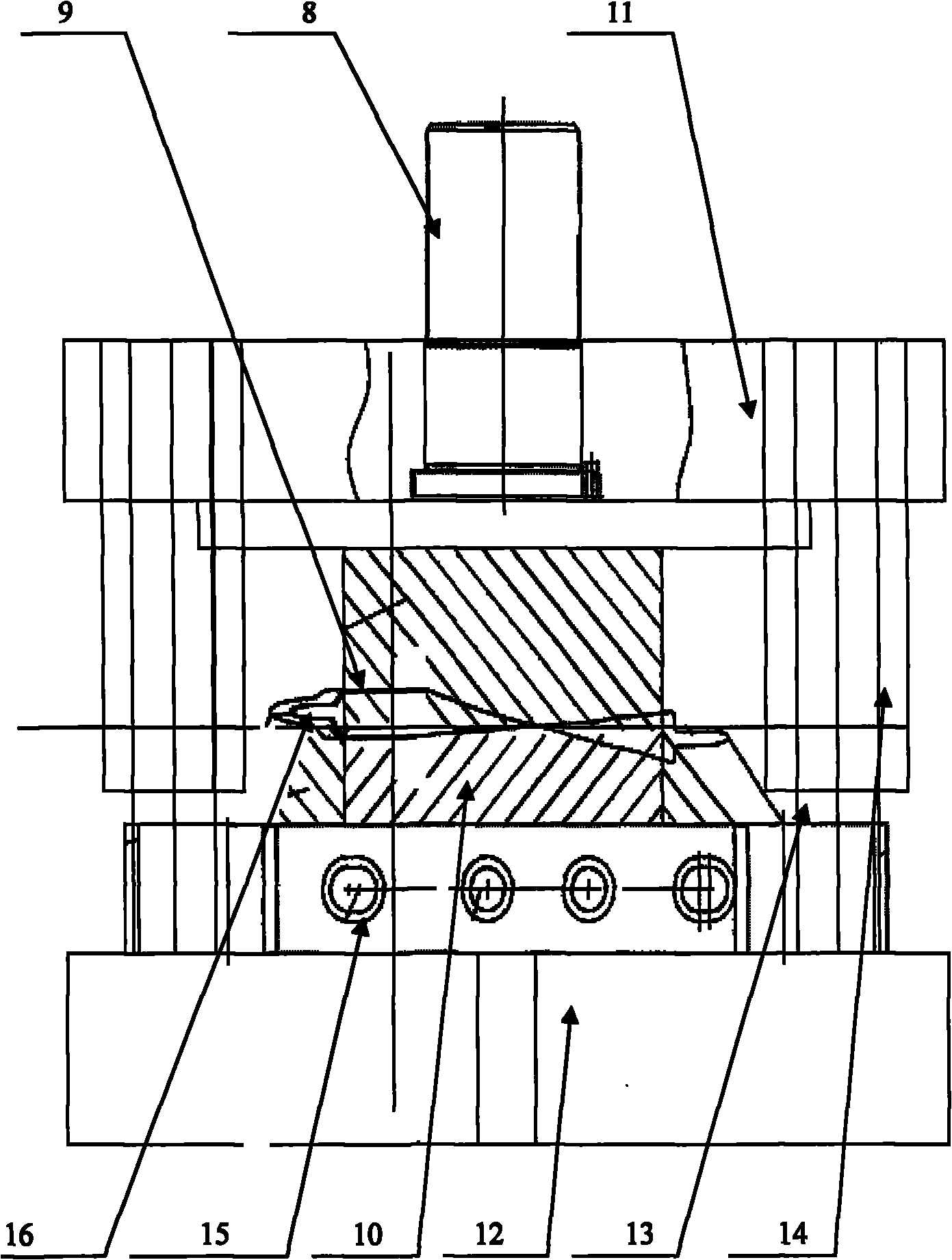

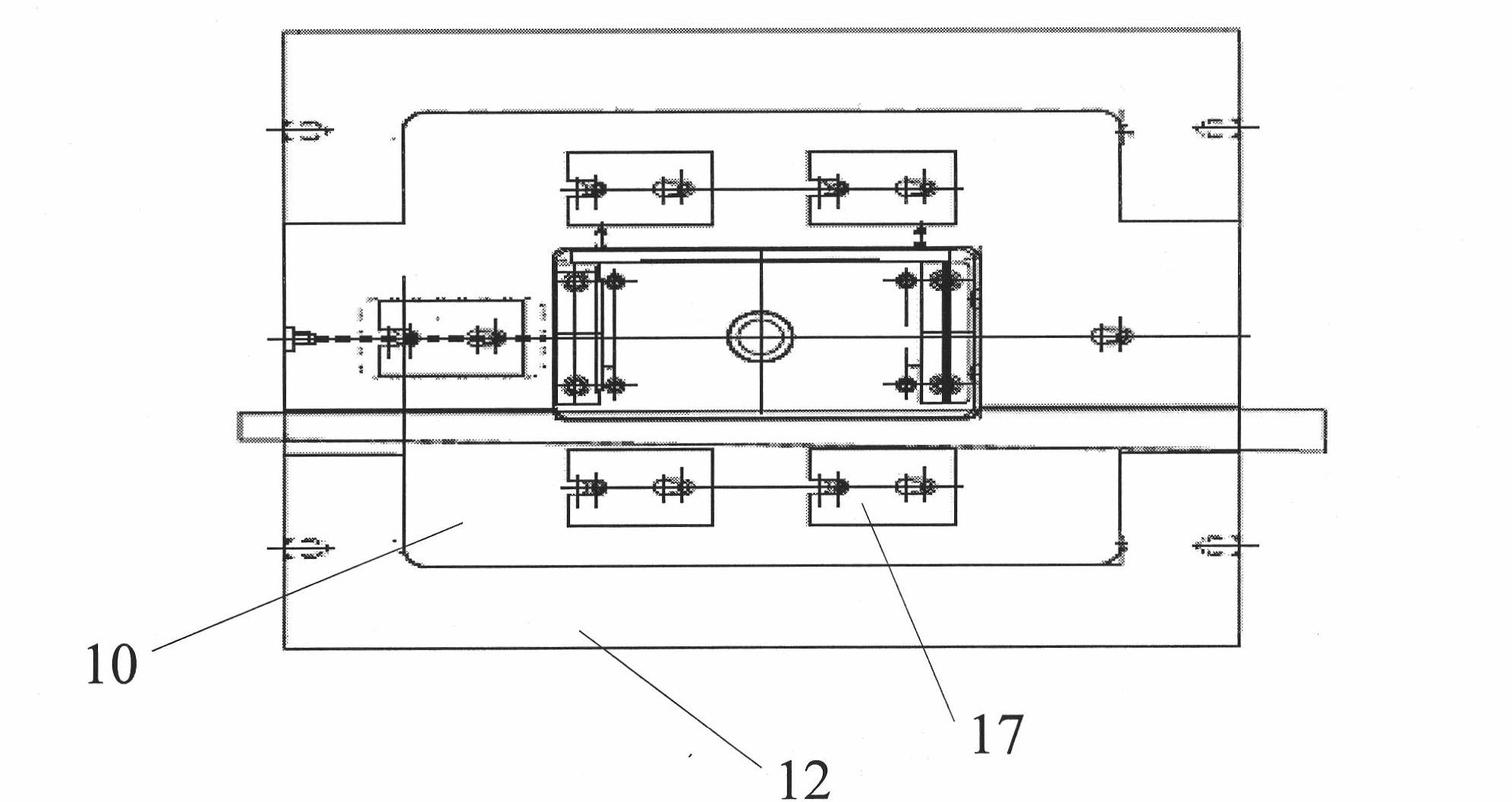

[0028] Use bolts to fix the bearing plate on the lower mold, apply mold lubricant on the mold, place the upper and lower molds on the upper and lower mold bases respectively, and place the blade forgings in the upper and lower molds. There are two reverse arc sections, the reverse arc section of the air intake side starts from the 5mm inside the air intake side of the blade forging, and ends at the mold airfoil profile extending 3mm from the air intake side, and the reverse arc section of the exhaust side The arc section starts at 5mm inside the exhaust edge of the blade forging and ends at the die airfoil profile at the 3mm extension of the exhaust edge. The dimensional accuracy of the gap between the end surface of the impac...

Embodiment 2

[0035] Coat the glass lubricant on the surface of the pre-forged blade forging, the thickness of the glass lubricant is 0.4mm, then heat the blade forging to 40°C below the transformation point of the blade forging, and keep it warm for 25min.

[0036] Use bolts to fix the bearing plate on the lower mold, apply mold lubricant on the mold, place the upper and lower molds on the upper and lower mold bases respectively, and place the blade forgings in the upper and lower molds. There are two reverse arc segments, the reverse arc segment of the air intake side starts from the 4mm inside the air intake edge of the blade forging, and ends at the mold airfoil profile extending 3mm from the air intake edge, and the reverse arc segment of the exhaust edge The arc section starts from 4mm inside the exhaust edge of the blade forging, and ends at the die airfoil profile at the 3mm extension of the exhaust edge. The dimensional accuracy of the gap between the end surface of the impact plat...

Embodiment 3

[0043] Coat the glass lubricant on the surface of the pre-forged blade forging, the thickness of the glass lubricant is 0.5mm, and then heat the blade forging to 30°C below the transformation point of the blade forging, and keep it warm for 30min.

[0044]Use bolts to fix the bearing plate on the lower mold, apply mold lubricant on the mold, place the upper and lower molds on the upper and lower mold bases respectively, and place the blade forgings in the upper and lower molds. There are two reverse arc sections, the reverse arc section of the air inlet side starts from the 3mm inside the air inlet edge of the blade forging, and ends at the mold airfoil profile extending 2mm from the air inlet edge, and the reverse arc section of the exhaust edge The arc segment starts at 3mm inside the exhaust edge of the blade forging, and ends at the die airfoil profile at the 2mm extension of the exhaust edge. The dimensional accuracy of the gap between the end surface of the impact plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com