Mine-processing process for extracting iron, reducing fluorine and reducing potassium and sodium of oxide iron ore with high fluorine and high potassium and sodium

An iron oxide ore, high potassium sodium technology, applied in flotation, chemical instruments and methods, magnetic separation, etc., can solve the problems of furnace wall thickening, pellet pulverization, and coke performance damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

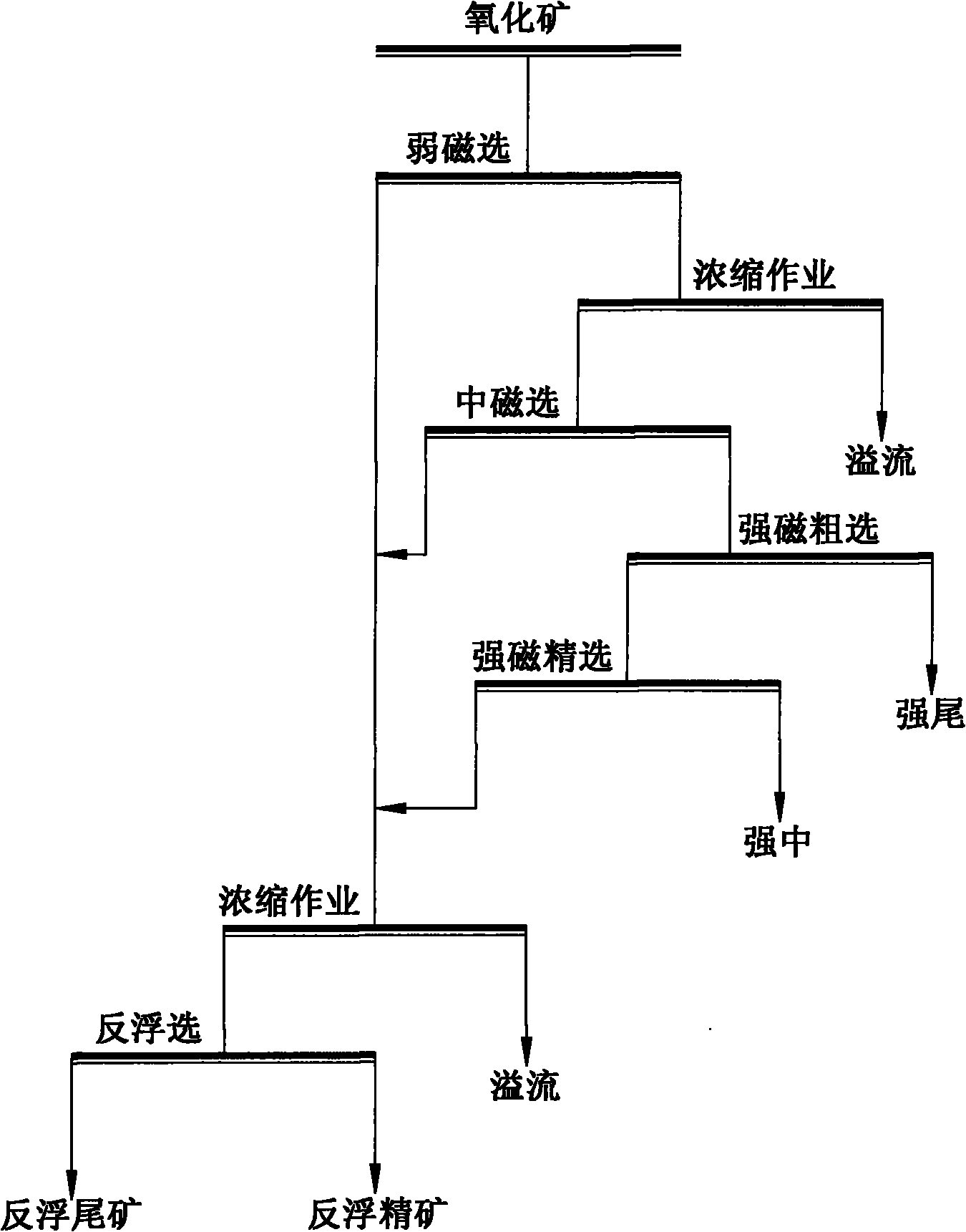

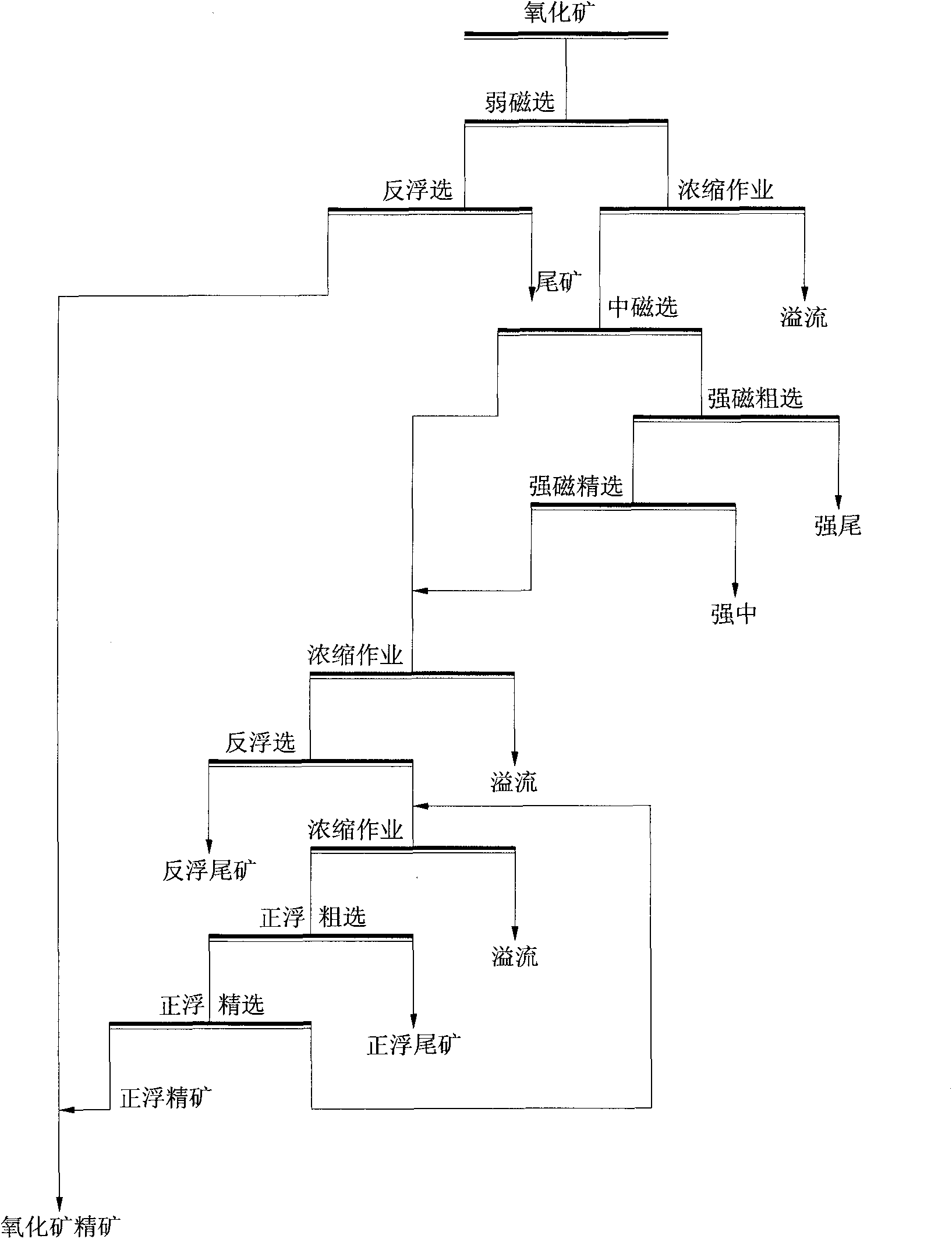

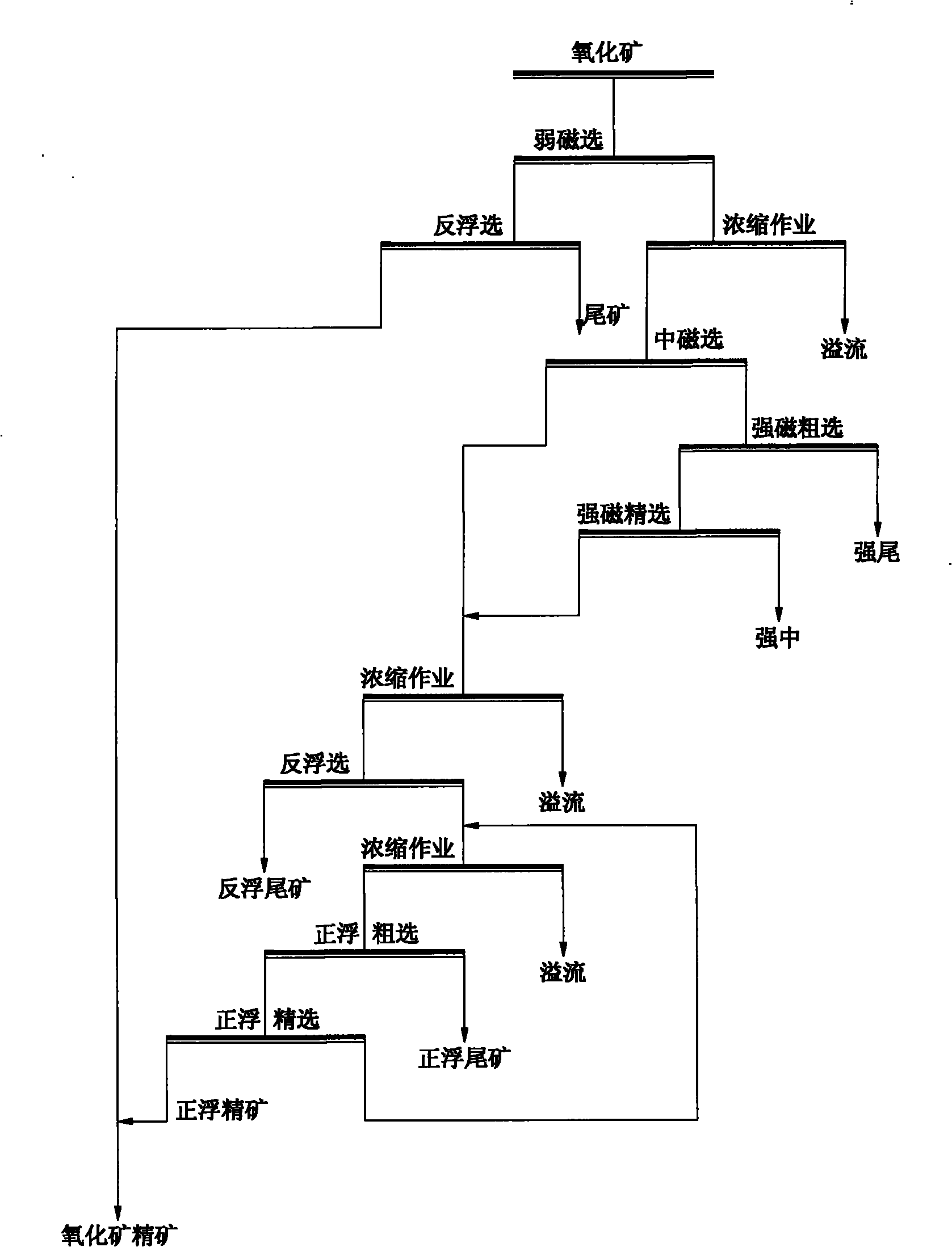

Method used

Image

Examples

Embodiment Construction

[0028] In order to further describe the present invention, the following is an example of Baotou Steel Baiyan Obo iron oxide ore dressing, in conjunction with the accompanying drawings and examples, the present invention high-fluorine, high-potassium sodium iron oxide ore to increase iron and reduce fluorine, reduce potassium and sodium mineral processing technology in more detail description of.

[0029] The ore sample is a medium-lean oxide ore. The results of multi-element analysis of the raw ore are shown in Table 1, the mineral composition analysis is shown in Table 2, and the iron phase analysis is shown in Table 3.

[0030] Table 1 Results of multi-element analysis of raw ore (%)

[0031]

Element

TF

FeO

SFe

Fe 2 o 3

F

SiO 2

MgO

CaO

content

31.8

8.9

9.3

7.29

18.05

Element

BaO

K 2 o

Na 2 o

P

S

ReO

Nb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic induction | aaaaa | aaaaa |

| Magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com