Unit cell of fuel battery

A fuel cell and single cell technology, applied in the direction of fuel cells, fuel cell parts, battery electrodes, etc., can solve problems such as increased load, increased mechanical load of electrolyte membrane, and insufficient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

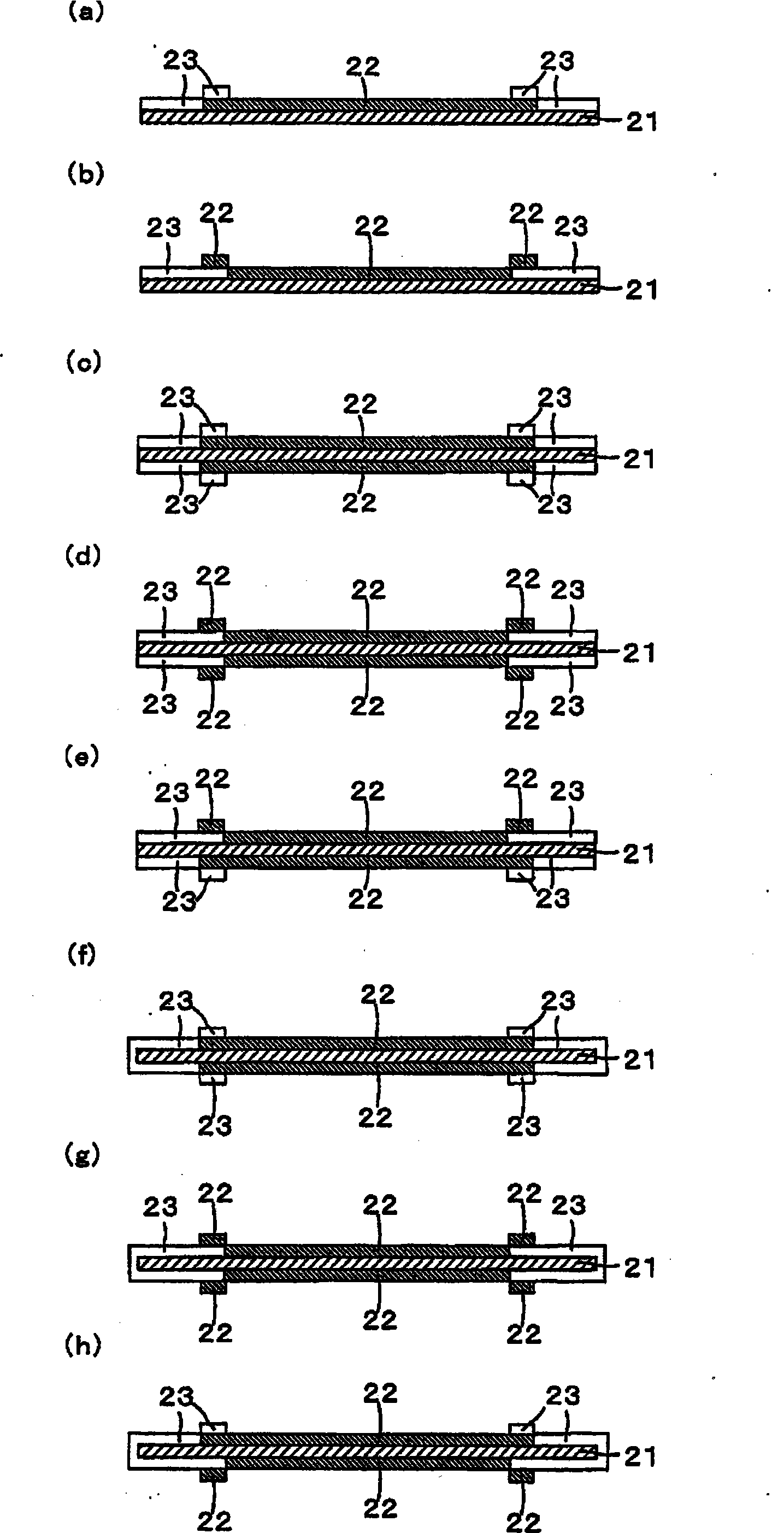

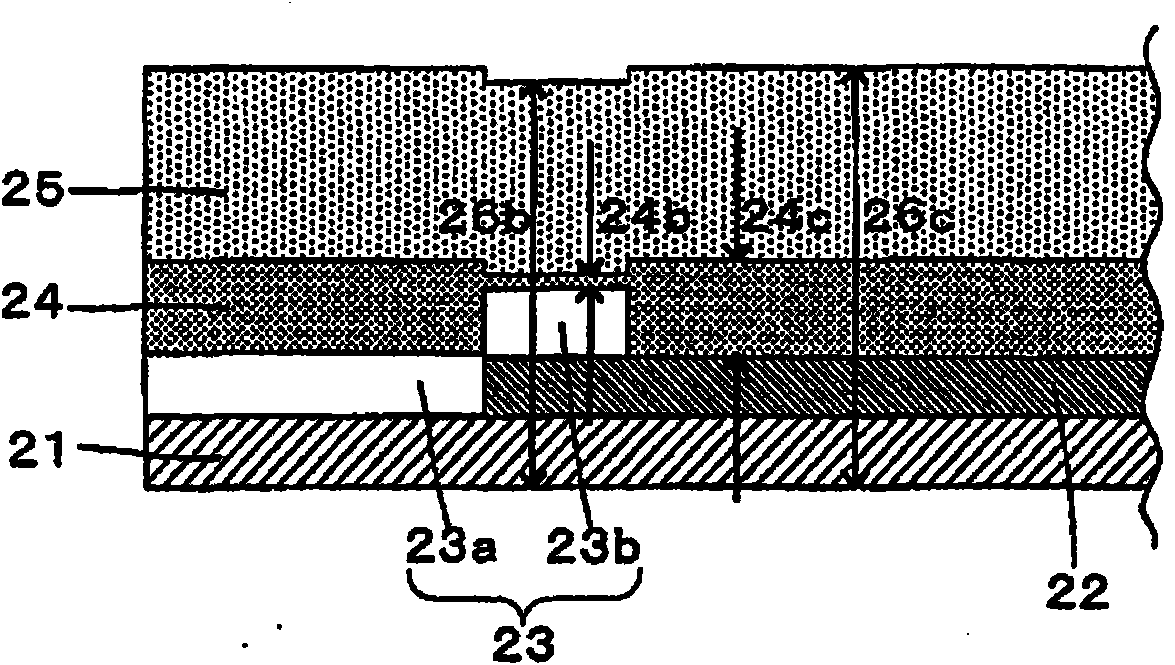

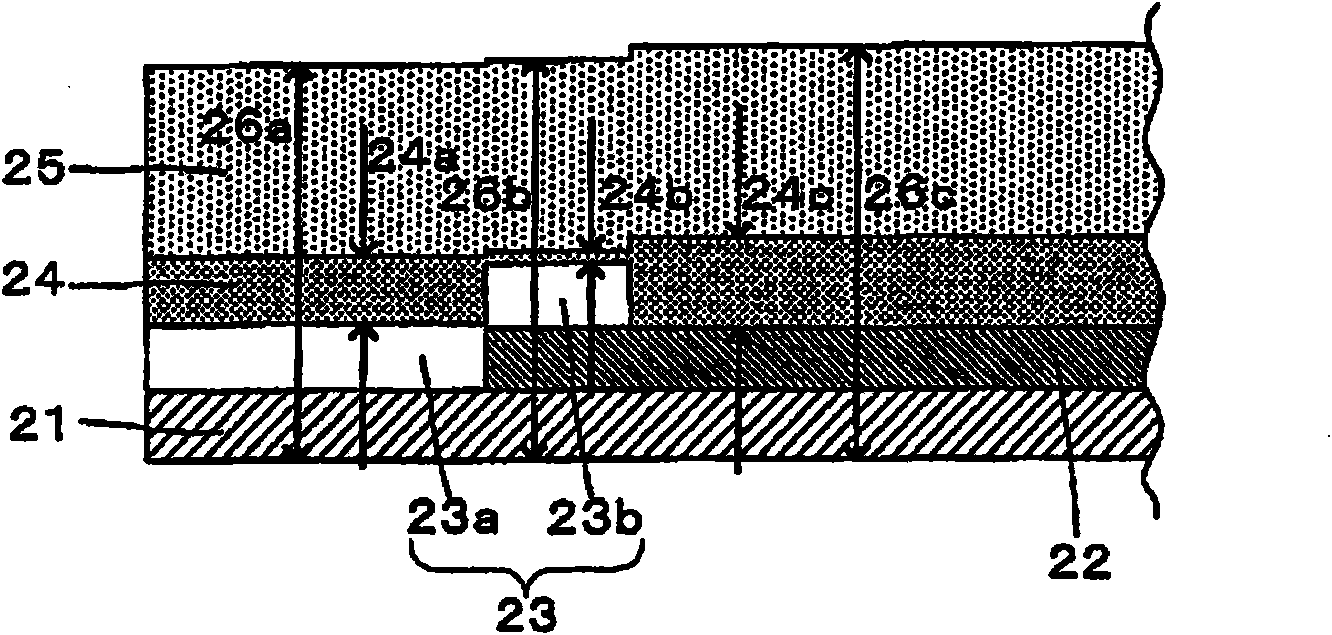

[0111] A unit cell of a fuel cell according to the present invention has a membrane electrode assembly having an anode electrode including an anode catalyst layer and a gas diffusion layer on one side of a solid polymer electrolyte membrane, and a pair of separators, and on the other side of the solid polymer electrolyte membrane. One side has a cathode electrode including a cathode catalyst layer and a gas diffusion layer, and the unit cell of the above-mentioned fuel cell is characterized in that, on at least one side of the anode side and the cathode side of the above-mentioned solid polymer electrolyte membrane, the above-mentioned anode or cathode catalyst layer It has a size and shape slightly smaller than that of the solid polymer electrolyte membrane and the gas diffusion layer, and the outer peripheral portion of the solid polymer electrolyte membrane and the gas diffusion layer exposed from the outer periphery of the anode or cathode catalyst layer The outer periphera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com