Heater coil device for preparing high resistance zone-melting monocrystalline silicon in vacuum condition

A technology for heating coils and zone melting of silicon, which is applied in the directions of single crystal growth, single crystal growth, self-zone melting method, etc., can solve the problem of low crystallization rate, inability to achieve continuous purification of large-diameter raw materials, and inability to obtain high-resistance single crystals and other problems to achieve the effect of preventing the collapse of the molten zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A heating coil device for preparing high-resistance melting silicon single crystals in a vacuum atmosphere, comprising a heating coil device for melting and purifying polysilicon in a vacuum zone and a heating coil device for vacuum crystallization of silicon single crystals, and the two devices are used in conjunction;

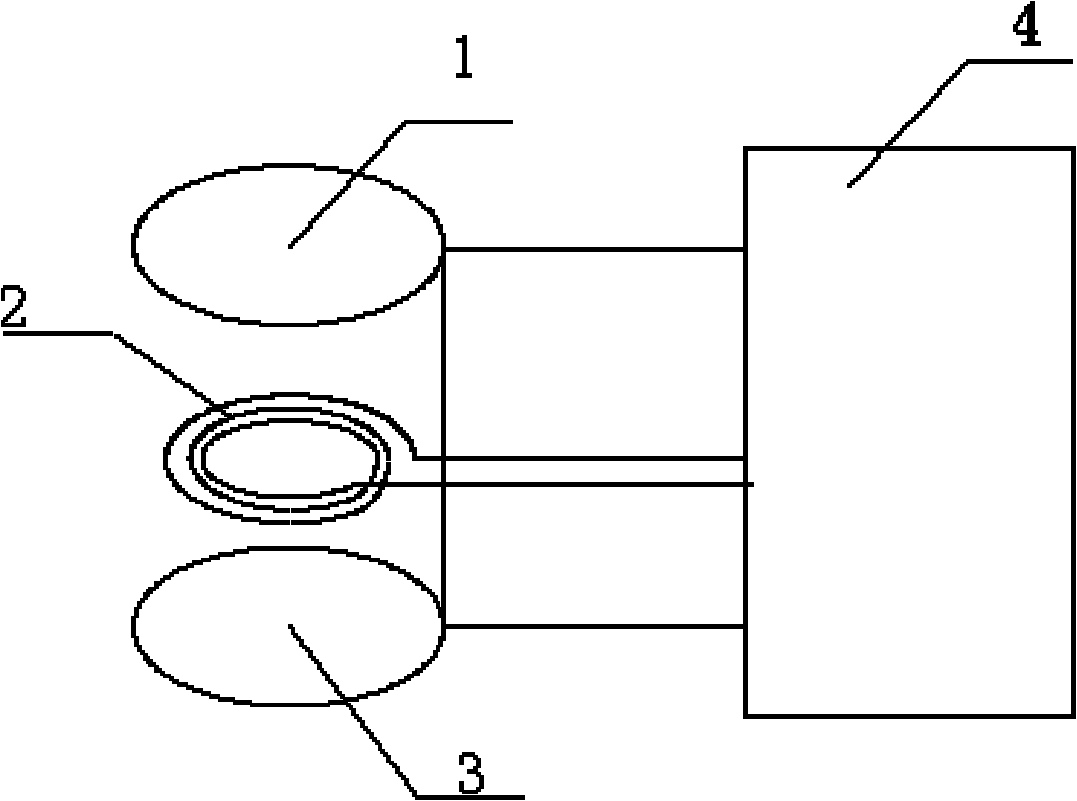

[0044] Such as figure 1 As shown, the polycrystalline silicon vacuum zone melting and purification heating coil device includes an upper short-circuit ring 1, a multi-turn heating coil 2, a lower short-circuit ring 3, and an upper short-circuit ring 1 from top to bottom. They are parallel to each other and perpendicular to the direction of crystal movement. Welded on the electrode cylinder 4, the diameter of the upper and lower short-circuit rings is slightly larger than the outer diameter of the multi-turn heating coil 2;

[0045] The distance from the upper short-circuit ring 1 to the multi-turn heating coil 2 is 7 mm, the distance from the lower sho...

Embodiment 2

[0053] A heating coil device for preparing high-resistance melting silicon single crystals in a vacuum atmosphere, including a heating coil device for melting and purifying polysilicon in a vacuum zone and a heating coil device for silicon single crystal crystallization, and the two devices are used in conjunction;

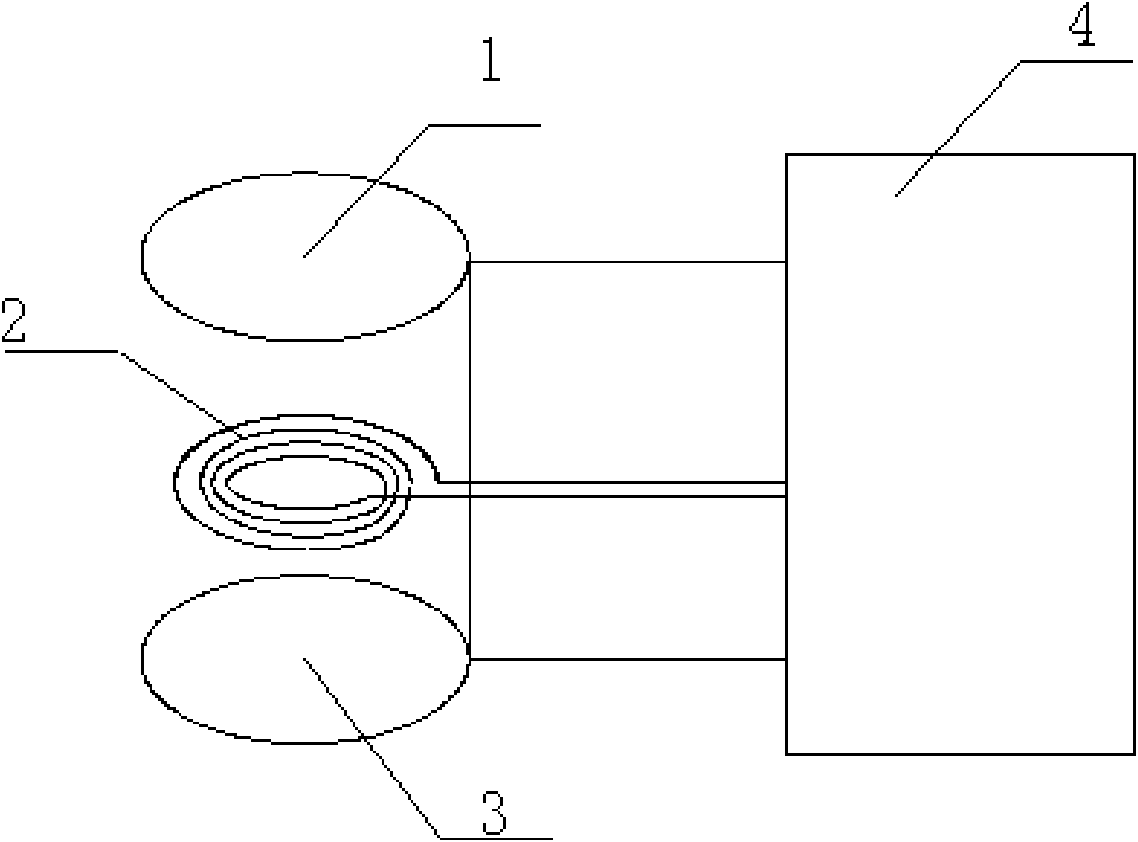

[0054] Such as figure 2 As shown, the polysilicon vacuum zone melting and purification heating coil device includes an upper short-circuit ring 1, a multi-turn heating coil 2, a lower short-circuit ring 3, and an upper short-circuit ring 1 from top to bottom, which are parallel to each other and perpendicular to the direction of crystal movement, and Welded on the electrode cylinder 4 respectively, and the diameter of the upper and lower short-circuit rings is slightly larger than the outer diameter of the multi-turn heating coil 2;

[0055] 1 The upper short-circuit ring 1 is 14mm away from the incense-type multi-turn heating coil, the distance between the lower...

Embodiment 3

[0064] A heating coil device for preparing high-resistance melting silicon single crystals in a vacuum atmosphere, including a heating coil device for melting and purifying polysilicon in a vacuum zone and a heating coil device for silicon single crystal crystallization, and the two devices are used in conjunction;

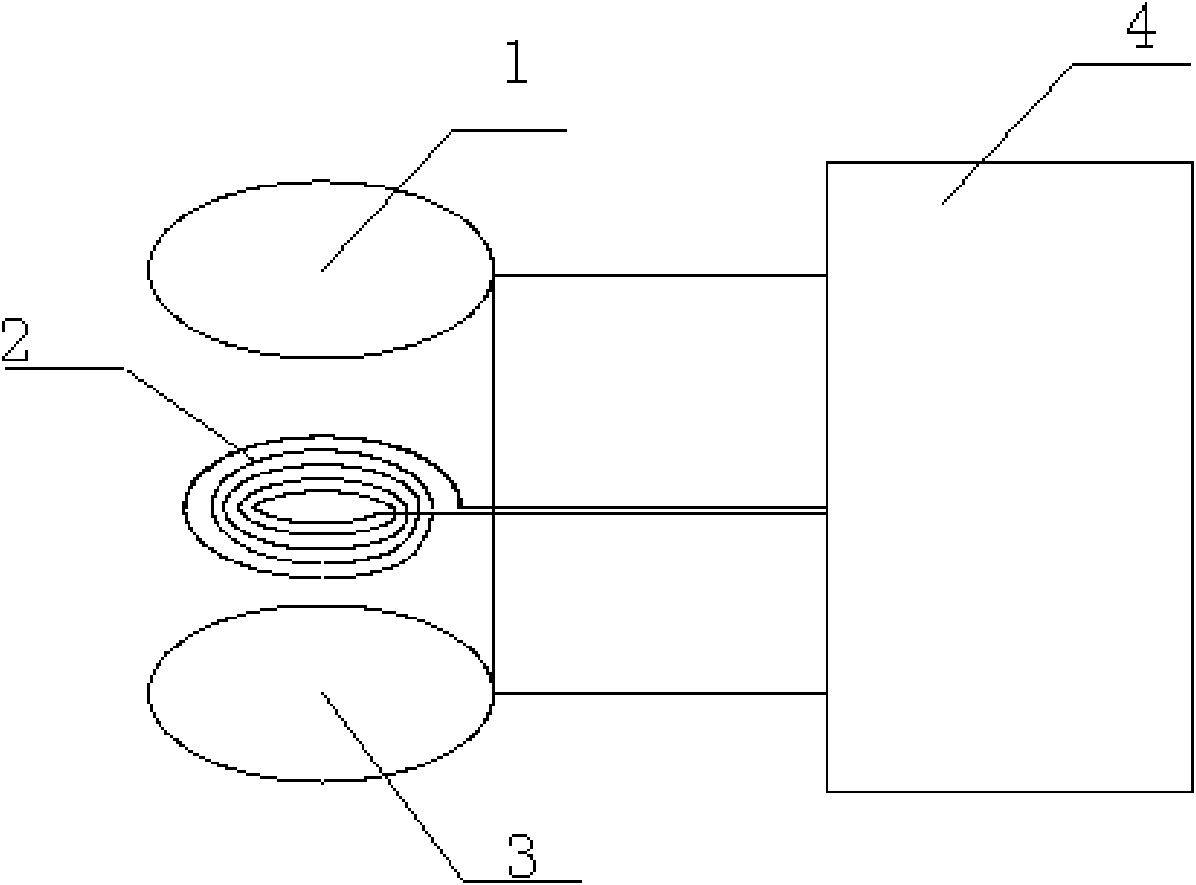

[0065] Such as image 3 As shown, the polysilicon vacuum zone melting and purification heating coil device includes an upper short-circuit ring 1, a multi-turn heating coil 2, a lower short-circuit ring 3, and an upper short-circuit ring 1 from top to bottom, which are parallel to each other and perpendicular to the direction of crystal movement, and It is fixedly connected to the electrode cylinder 4 by screws, and the diameter of the upper and lower short-circuit rings is slightly larger than the outer diameter of the multi-turn heating coil 2;

[0066] The upper short-circuit ring 1 is 10 mm away from the incense-type multi-turn heating coil 2 , and the distanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com