Process for compact natural gas liquefying and floating production

A floating production and natural gas technology, applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems of poor applicability at sea, low efficiency, and small processing capacity of nitrogen expansion process, and achieve poor applicability, easy installation, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

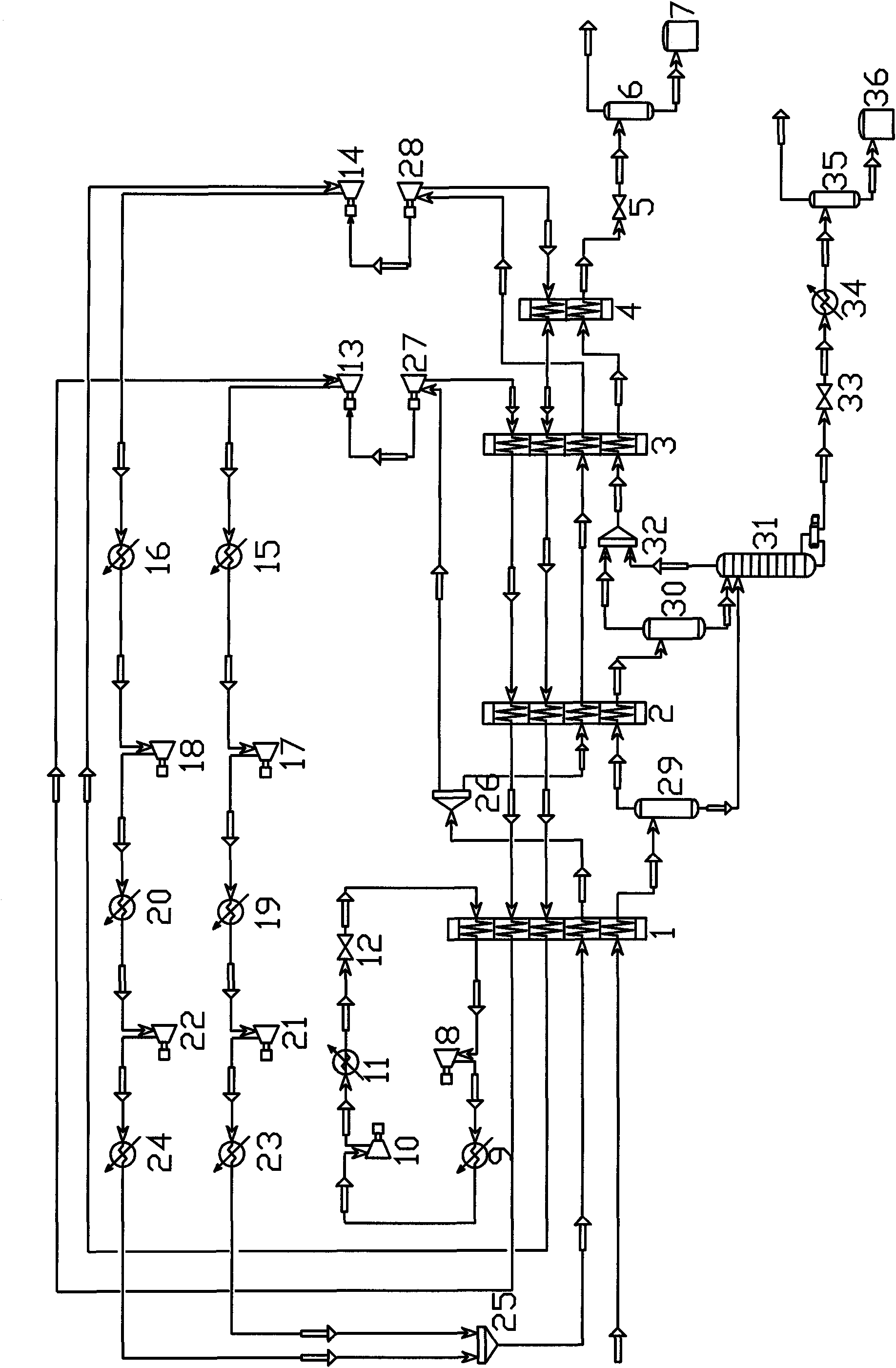

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0020] like figure 1 As shown, it is assumed that the pressure of the pretreated natural gas is 5.0MPa and the temperature is 34.5°C. The liquefaction process consists of a propane precooling cycle, a double nitrogen expansion refrigeration cycle, natural gas deheavy hydrocarbons, and a liquefaction pipeline.

[0021] In the propane pre-cooling cycle, propane is compressed to 1.6MPa by propane compressors 8 and 10, and after each stage of compression, it is cooled to 35°C by water coolers 9 and 11, and the propane is completely liquefied, and then the pressure is reduced to 0.13MPa, the temperature drops to -36°C. At this time, the propane is a gas-liquid two-phase, and enters the heat exchange cold box 1 to pre-cool natural gas and nitrogen refrigerants.

[0022] In the nitrogen expansion refrigeration cycle, the high-pressure nitrogen is pre-cooled t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com