Microwave medium ceramic material with low-temperature sintering spinel structure and preparation method thereof

A microwave dielectric ceramic and low-temperature sintering technology is applied in the field of microwave dielectric ceramic materials, low-temperature sintered spinel structure microwave dielectric ceramic materials and their preparation, which can solve the problems of reducing the size of microwave circuits, and achieve excellent microwave performance and simple chemical composition. , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

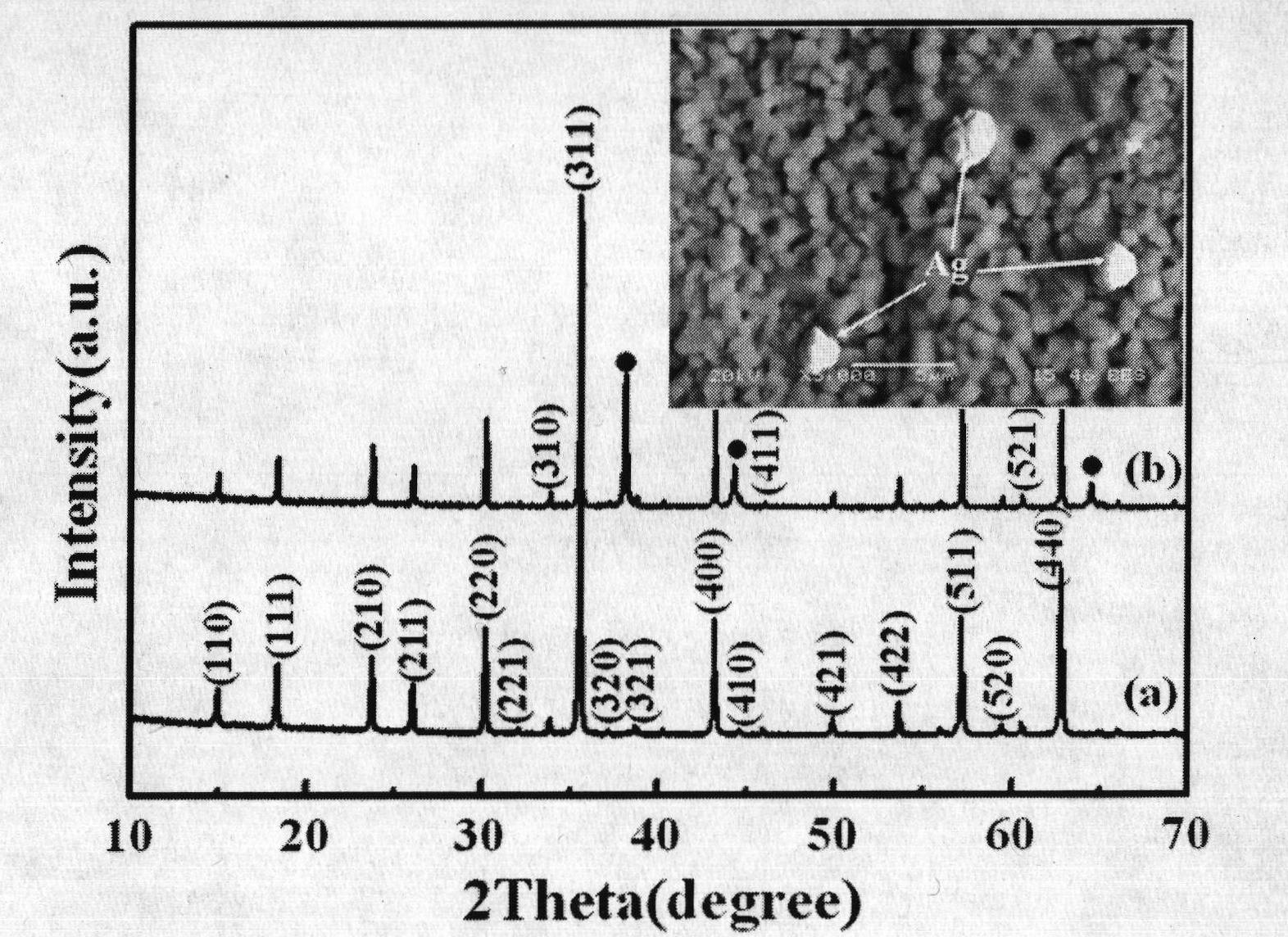

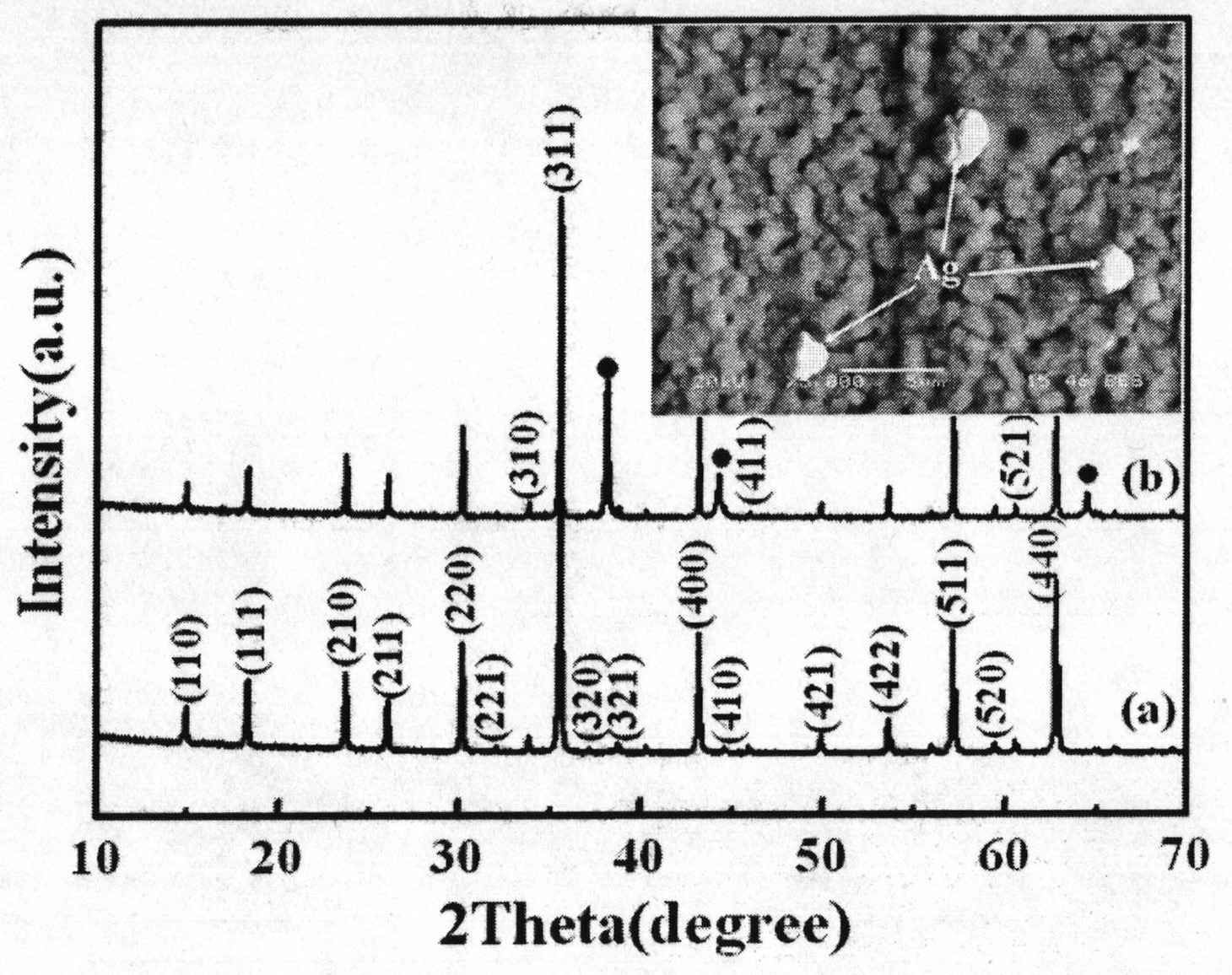

Image

Examples

Embodiment 1

[0019] (1) First, the chemical raw material Li 2 C0 3 , ZnO and TiO 2 Moore Billy 2 CO 3 :ZnO:TiO 2 = 1:1:3 to prepare the main powder;

[0020] (2) Then mix the prepared main powder evenly, add alcohol to the main powder according to the mass ratio of the main powder and alcohol as 1:1, and mix for 4 hours by wet grinding method, and grind it at 120-140 Dry at ℃, sieve with 80-mesh sieve, press into block after sieving, and then raise the pressed block raw material from room temperature to 850-950°C at a heating rate of 5°C / min Insulated for 4 hours, made into a sintered block;

[0021] (3) Pulverize the burnt block made above, add alcohol to the powder according to the mass ratio of powder and alcohol as 1:1, put it in a nylon jar and ball mill it for 4 hours, take it out, put it in an oven at 120-140 Dry at ℃, press into small discs after granulation, deglue at 500-600℃, and get porcelain material after cooling in the furnace, and then sinter the ceramic material at ...

Embodiment 2

[0023] (1) First, the chemical raw material Li 2 CO 3, ZnO and TiO 2 Moore Billy 2 CO 3 :ZnO:TiO 2 = 1:1:3 to prepare the main powder;

[0024] (2) Then mix the prepared main powder evenly, add alcohol to the main powder according to the mass ratio of the main powder and alcohol as 1:1, use wet grinding method to mix for 4 hours, and grind it at 120°C Dry, sieve with 80-mesh sieve, press into block after sieving, and then raise the pressed block raw material from room temperature to 850 °C at a heating rate of 5 °C / min and keep it at this temperature for 4 hours to prepare into a burnt block;

[0025] (3) pulverize the sintered block made above, carry out secondary ball milling for 4 hours, add 0.5% BaCu (B 2 o 5 ), made into powder, according to the volume ratio of powder and alcohol is 1:1, add alcohol to the powder, put it into a nylon tank and ball mill for 4 hours, take it out, put it in an oven and dry it at 120°C, and granulate Afterwards, it is pressed into sm...

Embodiment 3

[0027] (1) First, the chemical raw material Li 2 CO 3 , ZnO and TiO 2 Moore Billy 2 CO 3 :ZnO:TiO 2 = 1:1:3 to prepare the main powder;

[0028] (2) Then mix the prepared main powder evenly, add alcohol to the main powder according to the mass ratio of the main powder and alcohol as 1:1, use wet grinding method to mix for 8 hours, and grind it at 130°C Dry, sieve with 80-mesh sieve, press into block after sieving, and then raise the pressed block raw material from room temperature to 850 °C at a heating rate of 5 °C / min and keep it at this temperature for 4 hours to prepare into a burnt block;

[0029] (3) pulverize the burnt block made above, carry out secondary ball milling for 4 hours, add BaCu (B 2 o 5 ), and made into powder, according to the volume ratio of powder and alcohol is 1:1, add alcohol to the powder, put it into a nylon tank and ball mill for 4 hours, take it out, put it in an oven and dry it at 125°C, and granulate After that, it is pressed into small...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Τf | aaaaa | aaaaa |

| Εr | aaaaa | aaaaa |

| Εr | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com