Moving-bed biofilm oxidation ditch

A moving bed biofilm and oxidation ditch technology, which is applied in the field of high-efficiency moving bed biofilm oxidation ditch, can solve the problems of limited denitrification and phosphorus removal effect of the oxidation ditch, and large floor area, so as to improve the efficiency of oxygen mass transfer and utilization, occupy The effect of small area and long residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

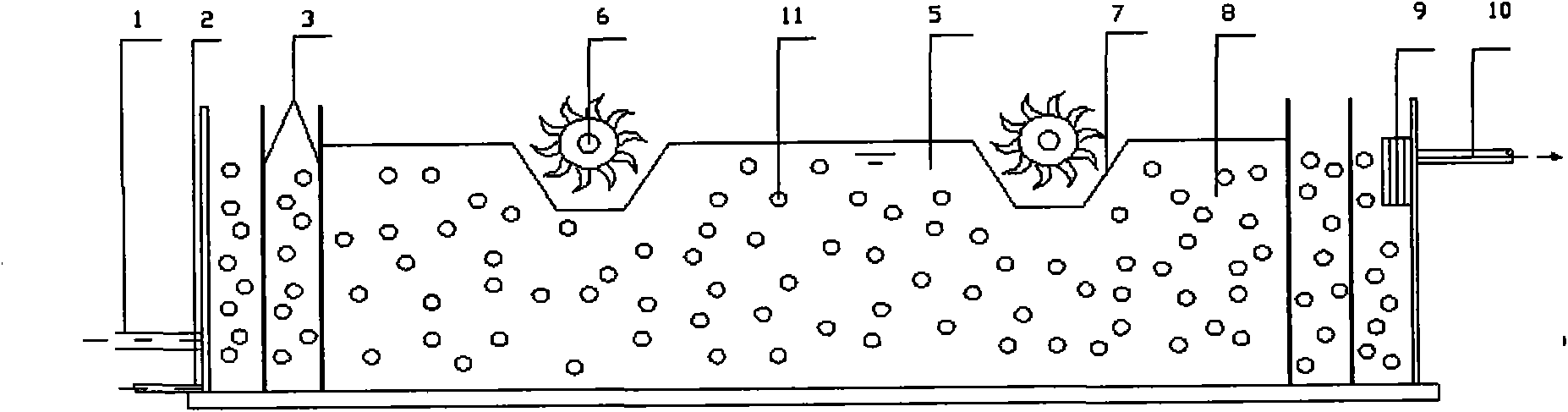

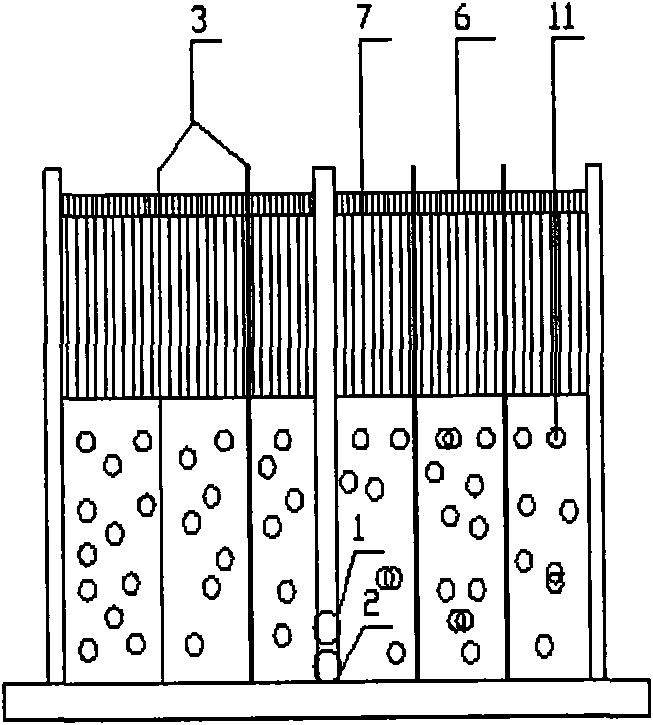

[0027] like Figure 1-3 The shown mechanical aeration moving bed biofilm oxidation ditch, the oxidation ditch adopts a single ditch type, including a ditch body, the ditch body is provided with a water inlet 1, a water outlet 10 and a mud outlet 2, and the ditch body is provided with a guide wall 3 And the aeration rotary brush 6, the ditch is filled with movable filler 11, the aeration rotary brush 6 is provided with a rotary brush screen 7, and the water outlet 10 is provided with a water outlet screen 9.

[0028] The mobile filler 11 is a hollow cylindrical filler made of polypropylene with a density of 0.98g / cm 3 , the height-diameter ratio is 0.5, and the specific surface area is 500m 2 / m 3 .

[0029] The oxidation ditch is aerated by the aeration rotary brush 6. In order to make the moving filler 11 and the mud-water mixture circulate in the ditch body, a rotary brush screen 7 is set outside the aeration rotary brush 6. 15-25cm.

[0030] The water outlet screen 9 i...

Embodiment 2

[0037] like Figure 4-6 The shown blast aeration moving bed biofilm oxidation ditch, the oxidation ditch adopts a single ditch type, including a ditch body, the ditch body is provided with a water inlet 1, a water outlet 10 and a mud outlet 2, and the ditch body is provided with a diversion wall 3. The flow propeller 12 and the microporous aeration pipe 13 are filled with movable fillers 11 in the ditch. The water outlet 10 is provided with a water outlet screen 9, and the water outlet screen 9 is placed in the pool of the water outlet 10.

[0038] The movable filler 11 is a hollow cylindrical filler made of polyethylene with a density of 0.95g / cm 3 , the height-diameter ratio is 0.3, and the specific surface area is 300m 2 / m 3 .

[0039] On the inner side of the pool of the mud discharge port 2, there is a mud discharge screen. The mud discharge screen is made into a cylindrical shape, and one end is open to connect with the mud discharge pipeline, and the other end is bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com