Sandy alumina preparation method

A technology of aluminum oxide and aluminum hydroxide, applied in the field of light metal metallurgy, can solve the problem of inability to circulate in the preparation process, and achieve the effects of shortened decomposition time, good fluidity and uniform particle distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

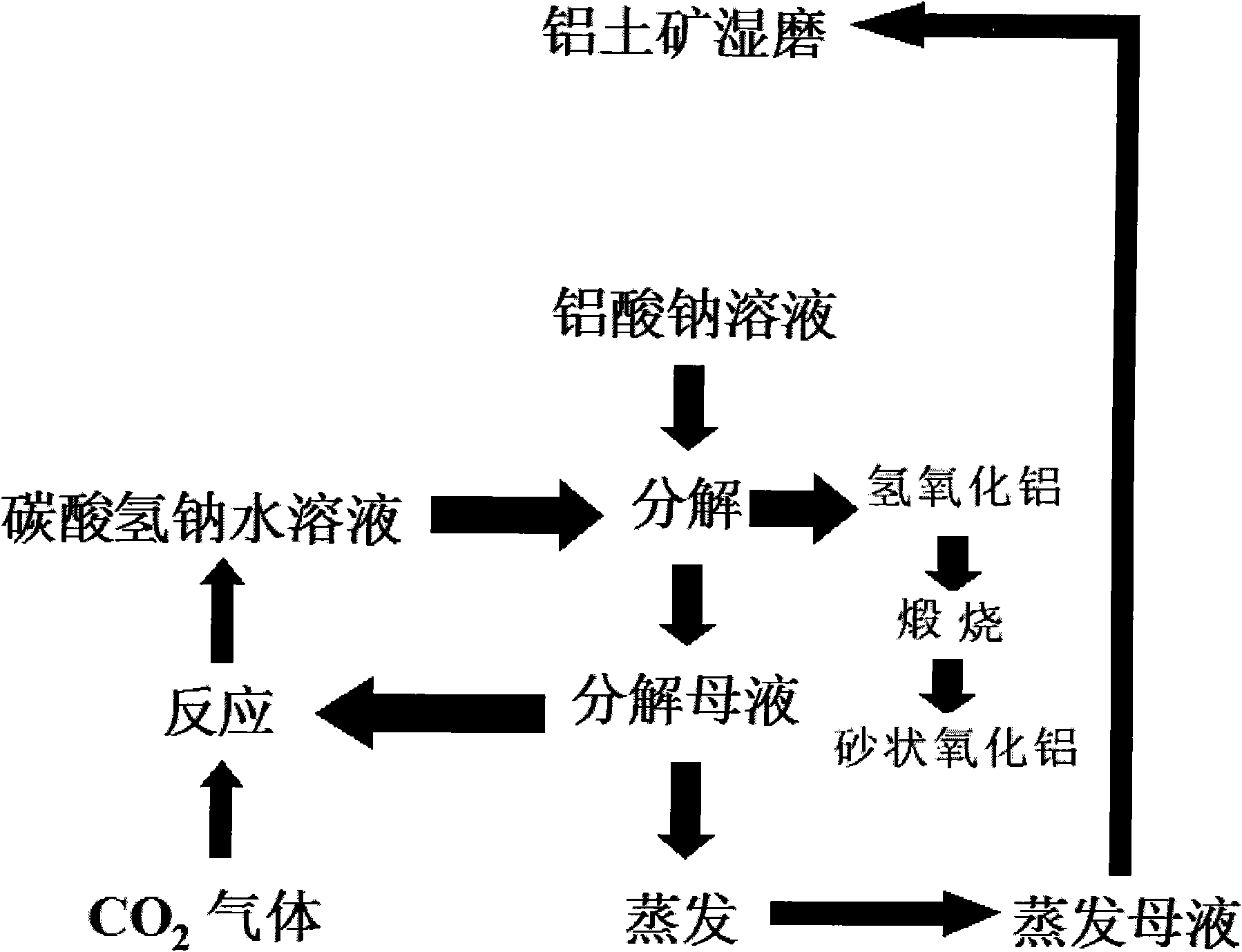

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Evaporate the sodium aluminate semen after desilication in industrial alumina production to the composition: Na 2 O180g / L, Al 2 o 3 211.5g / L, molar ratio 1.4. Get sodium bicarbonate 50g and dissolve in the deionized water of 1000mL, obtain the aqueous solution of the sodium bicarbonate of 50g / L.

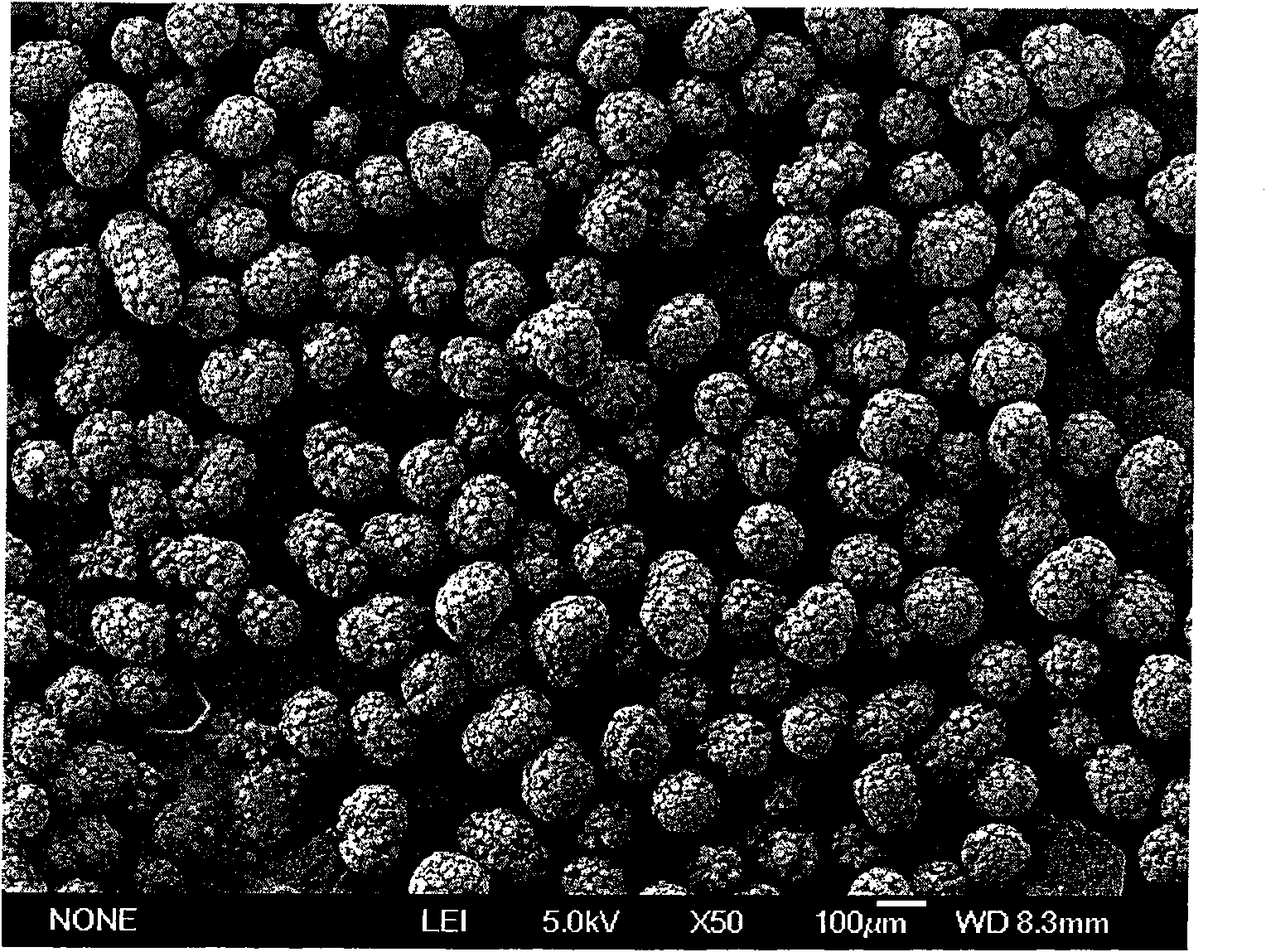

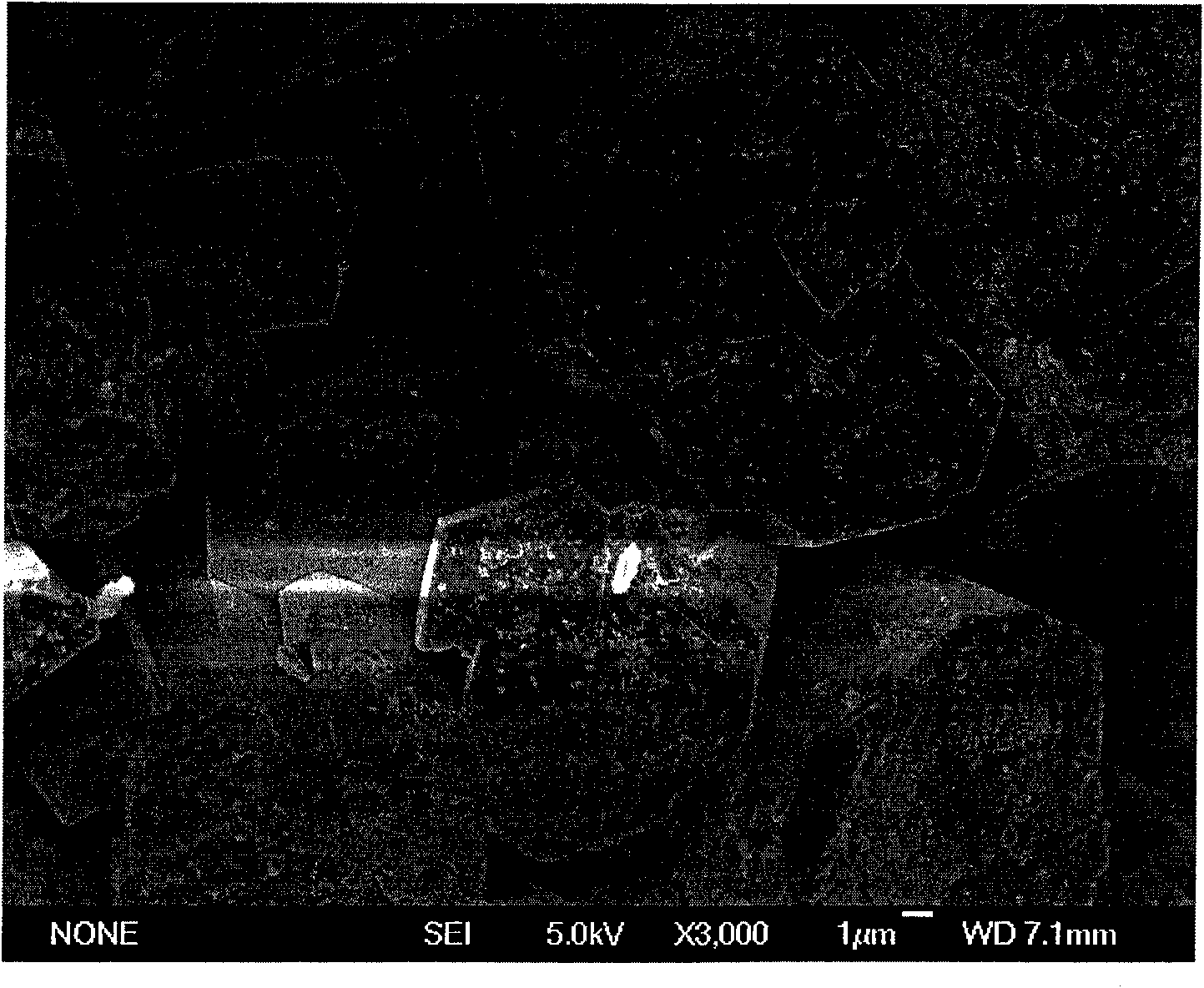

[0031] Add sodium bicarbonate aqueous solution to the sodium aluminate semen dropwise at a rate of 1 mL / min. This process is carried out in a constant temperature water bath at 80°C. After the reaction is completed, the solid-liquid mixture is separated, and the solid phase is washed with water until the washing liquid is Neutral, dry at 80°C for 24 hours to obtain aluminum hydroxide product, and calcinate aluminum hydroxide at 1000°C for 2 hours to obtain sandy alumina product. The main component of decomposition mother liquor is sodium carbonate, this decomposition mother liquor is at 40 ℃, reacts with carbon dioxide gas for 2 hours, and sodium carbonate is converted into...

Embodiment 2

[0034] 50g / L aqueous sodium bicarbonate solution is added dropwise to the sodium aluminate solution at a rate of 1mL / min, the composition of the sodium aluminate solution is: Na 2 O 178.25g / L, Al 2 o3 195.5g / L, molar ratio 1.5, the process is carried out in a constant temperature water bath at 70°C, after the reaction, the solid-liquid mixture is separated, the solid phase is washed with water until the washing liquid is neutral, and dried at 80°C for 12 hours to obtain The aluminum hydroxide crystal product is calcined at 1000° C. for 2 hours to obtain a sandy alumina product. The average particle size of the alumina product in this method is 95 μm. The decomposed mother liquor reacts with carbon dioxide gas to obtain a sodium bicarbonate solution again, which is used as a raw material for preparing the sandy alumina of the present invention.

Embodiment 3

[0036] Add 100g / L aqueous sodium bicarbonate solution dropwise to the sodium aluminate solution at a rate of 1mL / min, the composition of the sodium aluminate solution is: Na 2 O 178.25g / L, Al 2 o 3 210.5g / L, molar ratio 1.4, the process is carried out in a constant temperature water bath at 60°C. After the reaction, the solid-liquid mixture is separated, the solid phase is washed with water until the washing liquid is neutral, and dried at 80°C for 24 hours to obtain The aluminum hydroxide product is calcined at 1000° C. for 2 hours to obtain a sandy alumina product, and the particle size of the alumina product in this method is 88 μm. The decomposed mother liquor reacts with carbon dioxide gas to obtain a sodium bicarbonate solution again, which is used as a raw material for preparing the sandy alumina of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com