Continuous esterification and ester exchange process used for producing biodiesel

A biodiesel, transesterification technology, applied in the petroleum industry, biofuels, fatty acid esterification and other directions, can solve problems such as increased energy consumption, and achieve the effect of extensive raw material adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

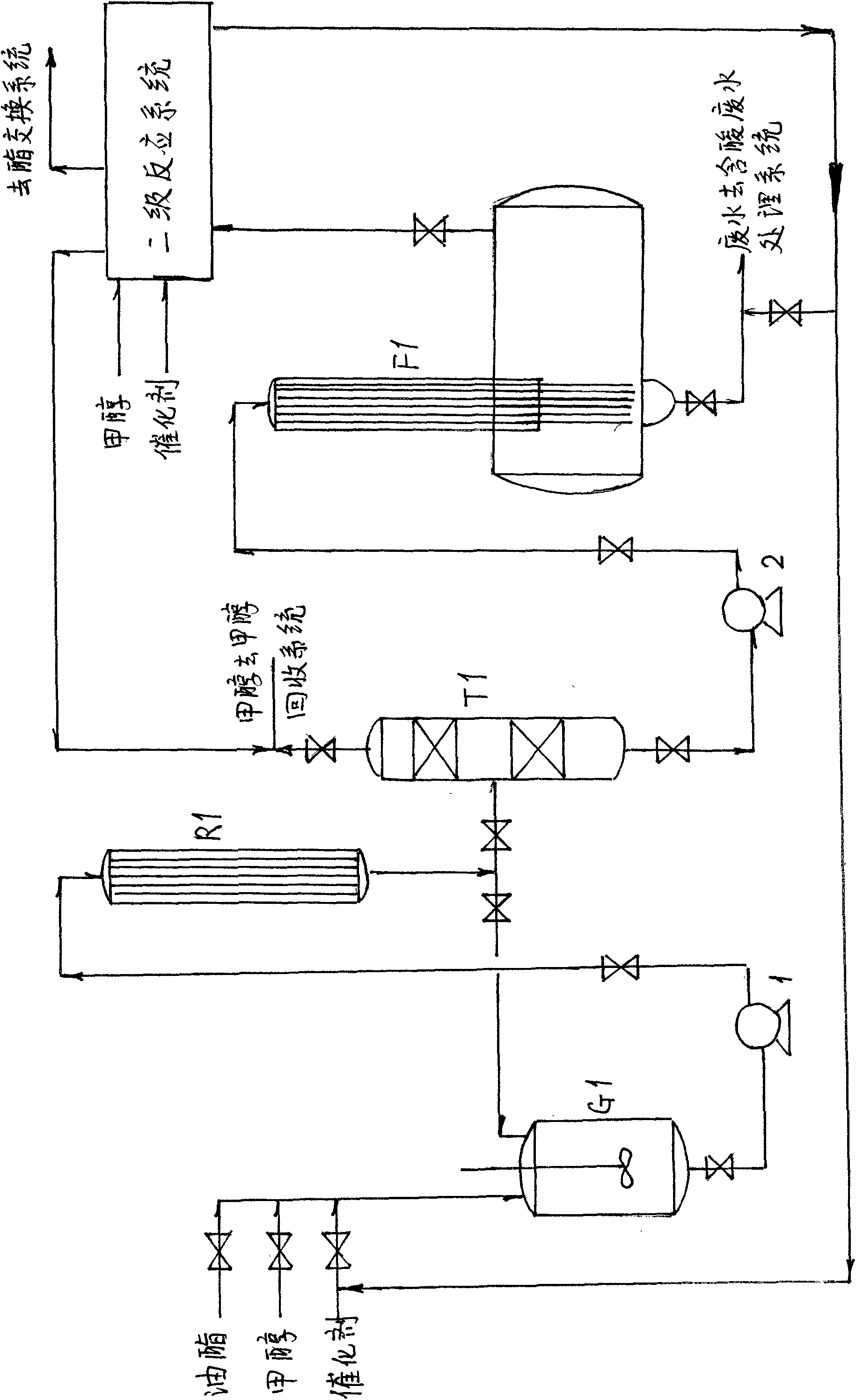

[0026] process such as figure 1 and figure 2 shown. The esterification fiber membrane reactor R1 is cylindrical with a height of 3000 mm and a diameter of 500 mm, filled with metal fibers with a diameter of 0.1 mm (provided by Nanjing Jinlian Technology Co., Ltd., the same below). The transesterification fiber membrane reactor R2 is cylindrical with a height of 3000mm and a diameter of 500mm, filled with metal fibers with a diameter of 0.1mm. The diameter of the water separation part of the fiber membrane water separator F1 is 600mm and the height is 5000mm.

[0027] One-level esterification feed, acid number 152mgKOH / g, water content is less than 1%, waste oil of saponification value 186, feed rate is 2000kg / hour, methanol (98%) feed rate is 400kg / hour, sulfuric acid ( 98%) feed rate was 16 kg / hour.

[0028] 12000kg / hour of material from the esterification fiber membrane reactor R1 returns to the esterification mixing tank R1, and the rest enters the methanol removal t...

Embodiment 2

[0034] One-level esterification feed, acid value 122mgKOH / g, water content is less than 1%, the acidified palm oil of saponification value 198, feed rate is 2000kg / hour, methanol (98%) feed rate is 400kg / hour, sulfuric acid (98%) The feed rate was 16 kg / hour. 12000kg / hour of material from the esterification fiber membrane reactor R1 returns to the esterification mixing tank R1, and the rest enters the methanol removal tower T1.

[0035] Secondary esterification feed, methanol (98%) feed rate is 200kg / hour, sulfuric acid (98%) feed rate is 4kg / hour. 12000kg / hour of material from the esterification fiber membrane reactor returns to the esterification mixing tank R1, and the rest enters the methanol removal tower.

[0036] Feed for transesterification, methanol (98%) feed rate is 200 kg / hour, solid KOH feed rate is 12 kg / hour. 11,000kg / hour of material from the transesterification fiber membrane reactor R2 returns to the transesterification mixing tank R2, and the rest enters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com