Formula of non-painted automobile bumper with metal luster and production process thereof

A technology for automobile bumpers and metallic luster, applied in the direction of bumpers, etc., can solve the problems of difficult painting process, low coating adhesion, inability to use for a long time, etc., and achieve excellent light aging resistance, short molding cycle, and not easy to fall off. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

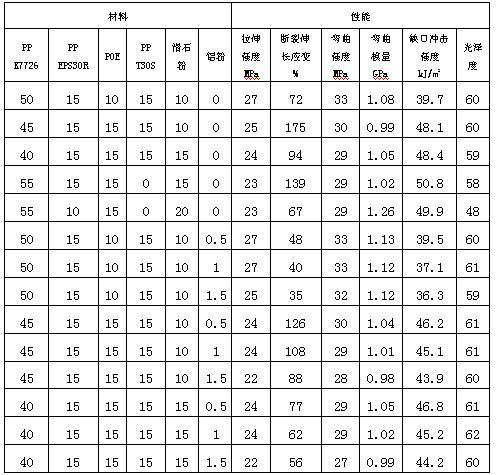

Examples

Embodiment 1

[0017] Embodiment 1 of the present invention: a paint-free automobile bumper with metallic luster, calculated in parts by weight, 50 parts of PP of grade K7726, 15 parts of grade EPS30R and 15 parts of grade T30S were mixed, and then mixed PP and 10 parts were mixed. Parts of POE, 1.5 parts of silver dollar aluminum powder and 10 parts of talc powder were blended, and mixture A was obtained after thorough mixing; mixture A was added to a twin-screw extruder, and melted at 200 ° C and screw speed of 300 rad / min and extruding and granulating to obtain plastic granules B; adding the plastic granules B into an injection molding machine for injection molding to obtain bumper C.

Embodiment 2

[0018] Embodiment 2 of the present invention: paint-free automobile bumper with metallic luster, calculated in parts by weight, mix 55 parts of brand K7726, 20 parts of brand EPS30R and 10 parts of PP of brand T30S, then mix the PP with 11 Parts of POE, 0.5 parts of silver dollar aluminum powder and 12 parts of talc powder were blended, and mixture A was obtained after thorough mixing; mixture A was added to a twin-screw extruder and melted at 230 ° C and screw speed of 300 rad / min and extruding and granulating to obtain plastic granules B; adding the plastic granules B into an injection molding machine for injection molding to obtain bumper C.

Embodiment 3

[0019] Embodiment 3 of the present invention: paint-free automobile bumper with metallic luster, calculated in parts by weight, 45 parts of PP of grade K7726, 15 parts of grade EPS30R and 5 parts of grade T30S were mixed, and then mixed PP and 12 parts were mixed. Parts of POE, 1 part of silver dollar aluminum powder and 20 parts of talc powder were blended, and mixture A was obtained after thorough mixing; mixture A was added to a twin-screw extruder, and melted at 170 ° C and screw speed of 300 rad / min and extruding and granulating to obtain plastic granules B; adding the plastic granules B into an injection molding machine for injection molding to obtain bumper C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com