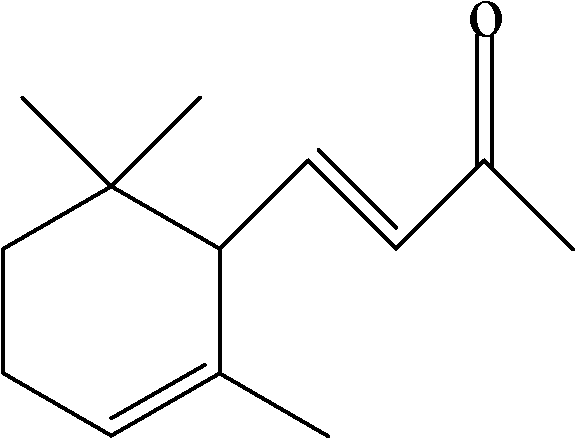

Method for synthesizing 4,5-epoxy-alpha-ionone

A technology of ionone and synthesis method, which is applied in 4 fields, can solve the problems of many by-products, difficult recovery, low product selectivity, etc., and achieve the effect of simple process and no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Add 20.0ml of α-ionone, 10.0ml of chloroform and 0.50g of Au / MCM-41 molecular sieve catalyst into the autoclave, feed 1.0Mpa oxygen, react at 60°C for 12h, and detect the reaction solution by GC-MS chromatography, α - The conversion of ionone is 98%, the selectivity of 4,5-epoxy-α-ionone is 75%.

Embodiment 2-4

[0018] According to the method and steps of Example 1, but the solvent used is ethanol, acetonitrile, acetone. The results are respectively: the conversion rate of α-ionone is 75%, the selectivity of 4,5-epoxy-α-ionone is 60%; the conversion rate of α-ionone is 91%, 4,5-epoxy The selectivity of -α-ionone was 63%; the conversion rate of α-ionone was 95%, and the selectivity of 4,5-epoxy-α-ionone was 70%.

Embodiment 5

[0020] According to the method and steps of Example 1, but the reaction time is 8h. The results were: the conversion rate of α-ionone was 81%, and the selectivity of 4,5-epoxy-α-ionone was 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com