Multi-layer printed circuit board machining process

A multi-layer circuit board and processing technology, which is applied in the direction of multi-layer circuit manufacturing, etc., can solve the problems of low residual copper rate, low alignment accuracy, and inconsistency of finished product size, so as to overcome the inaccurate alignment and high alignment. High precision and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

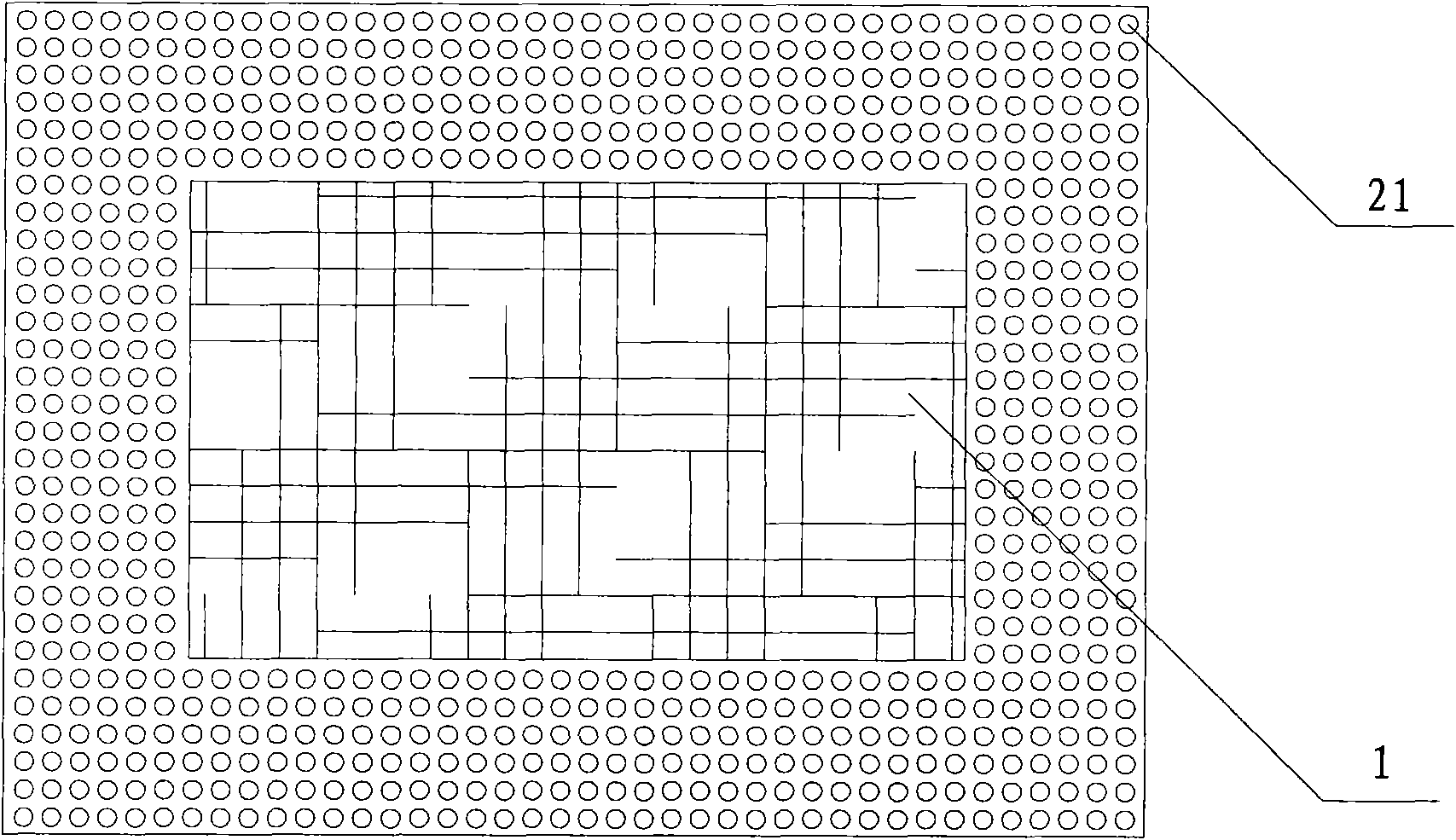

[0030] see image 3

[0031] The multilayer printed circuit board processing technology provided in this embodiment includes the following steps in sequence:

[0032] 1) Make a line pattern 1 and a frame pattern on the copper clad laminate, the frame pattern is composed of a frame pattern I2 and a frame pattern II3, from the center area of the copper clad laminate to the outside: line pattern 1, frame pattern I2, frame pattern II3 . The structure of the frame pattern I is a circular copper-clad point 21, and the exposed substrate is between the circular copper-clad points 21; between bare substrates. Among them, the interval between the circular copper clad points 21 is 0.5 mm to 1 mm, the diameter of the circular copper clad points ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com