Method for measuring working junction temperature and thermal resistance of electronic component by utilizing vacuum environment

A technology of electronic components and vacuum environment, applied in the field of research and development, can solve the problem of limited temperature-sensitive parameters of temperature measurement, and achieve the effect of reducing measurement error and reducing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

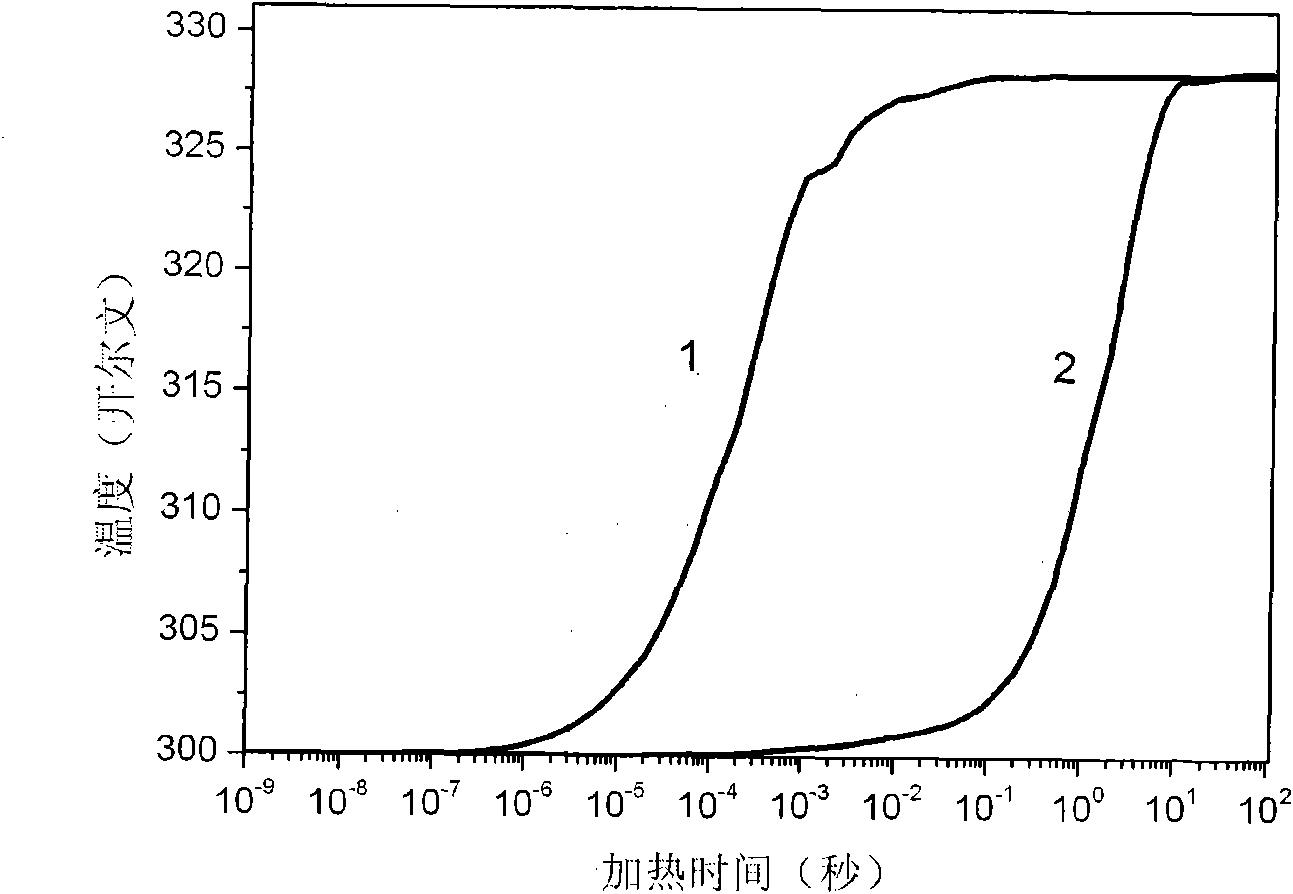

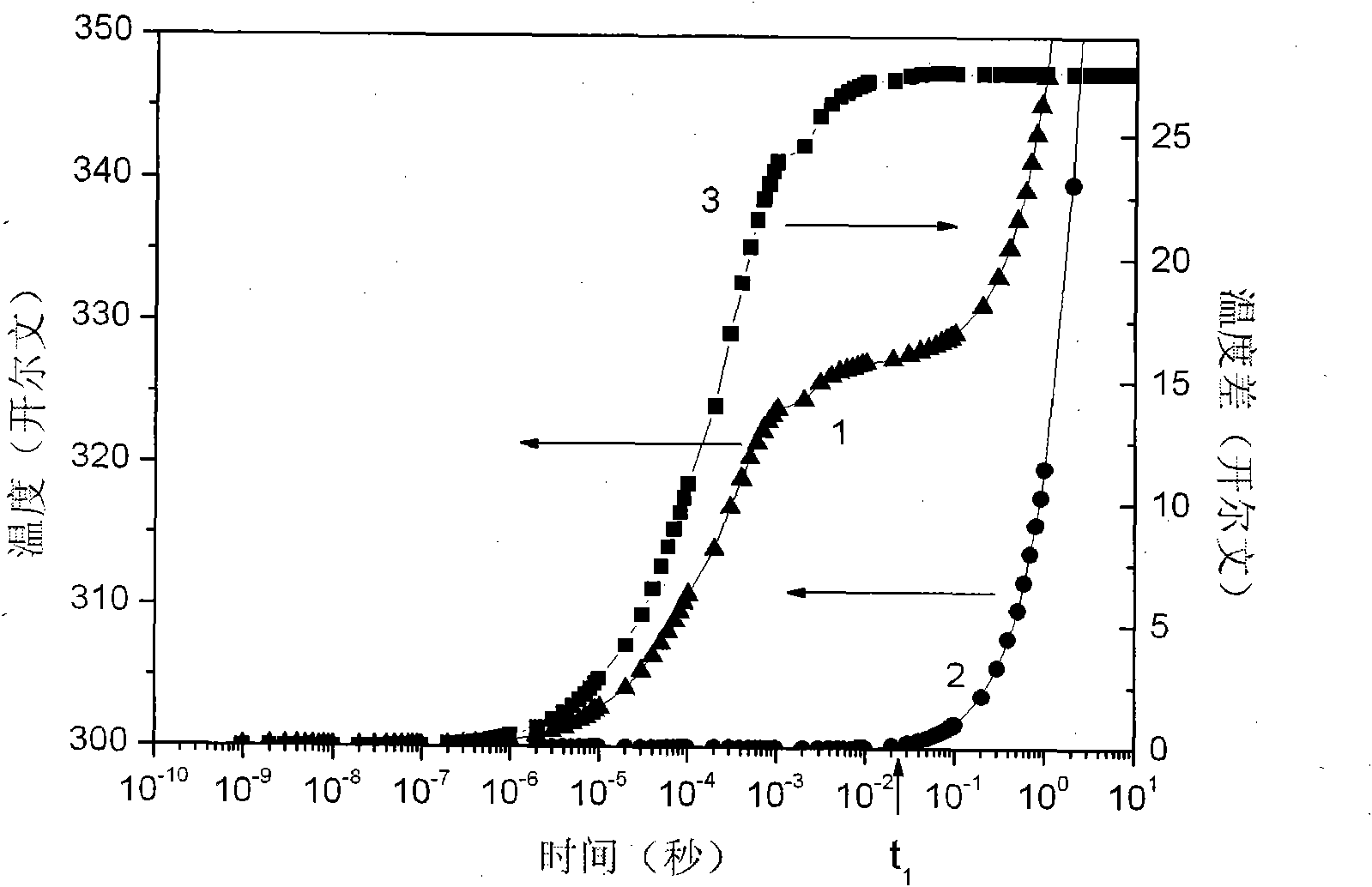

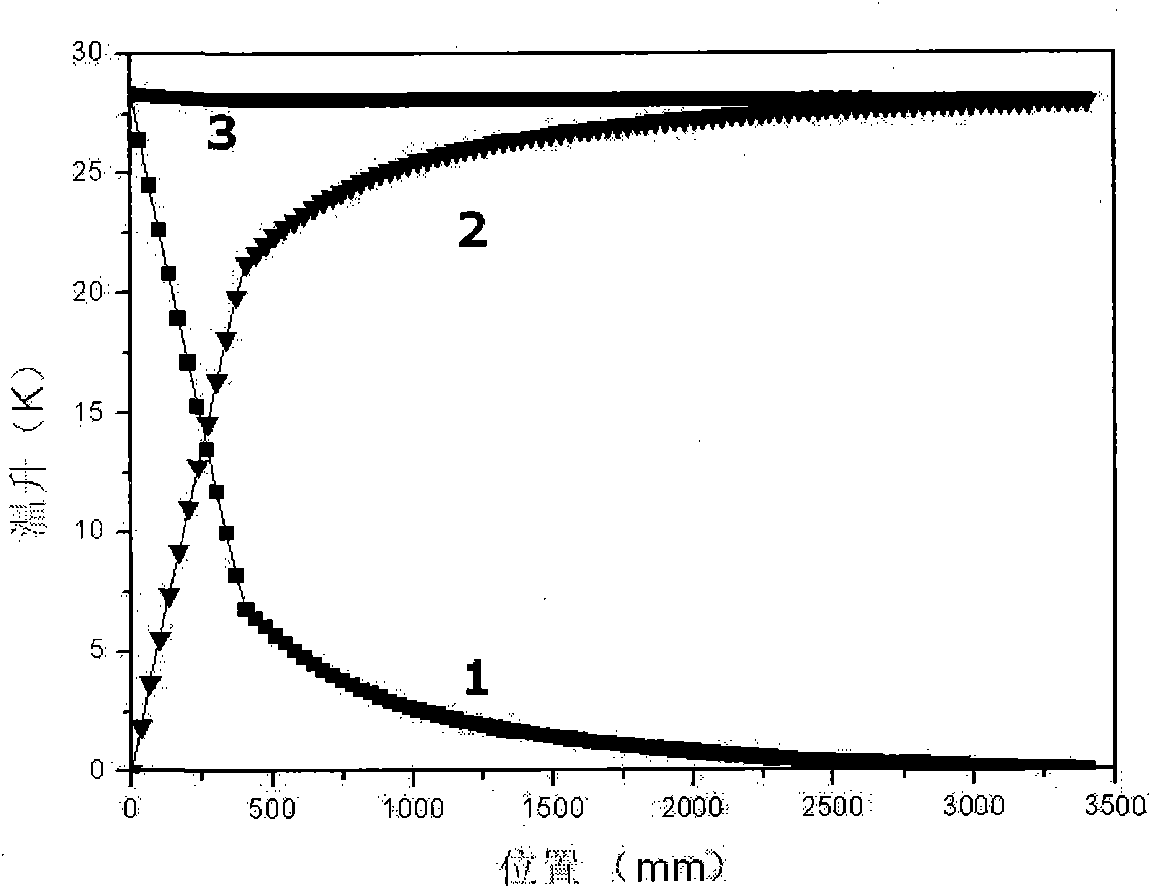

Embodiment Construction

[0035] 1. Use a vacuum system 1 that is connected to an external measuring device via internally sealed terminals. The device under test is power VDMOS, normal working voltage V=3.5V, I=1.2A, working power p=V*I=4.2W, working power is controlled by computer;

[0036] 2. Select two temperature-sensitive resistors. In this embodiment, two 100-ohm platinum resistors are used. One is placed on the upper part of the shell, and the other is placed on the bottom of the heating film. The other end of the film is in contact with the bottom of the shell. The two platinum resistors are connected to the external 1mA current source through the internal terminal. The voltages at both ends of the resistors are respectively connected to the high-speed acquisition board. The heating power of the heating film is connected to the external power supply. When the heating power is applied, the high-speed acquisition board is triggered to collect temperature sensitive data. The voltage across the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com